Torpedo ladle with mechanical limiting control system

A control system, torpedo tank technology, applied in the direction of manufacturing tools, casting melt containers, metal processing equipment, etc., can solve the problems of inaccurate and malfunctioning torpedo tanks, achieve good vertical tipping protection and avoid safety Accidents, the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to clearly illustrate the technical characteristics of the present invention, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

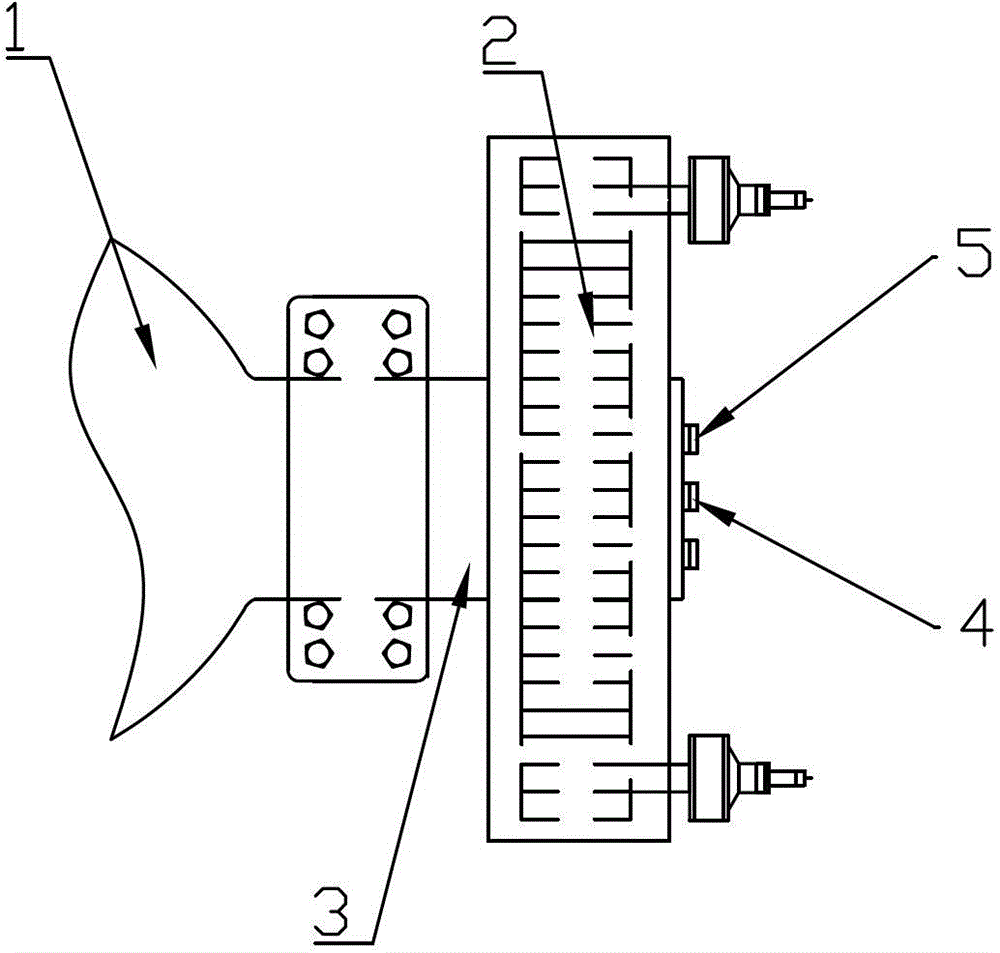

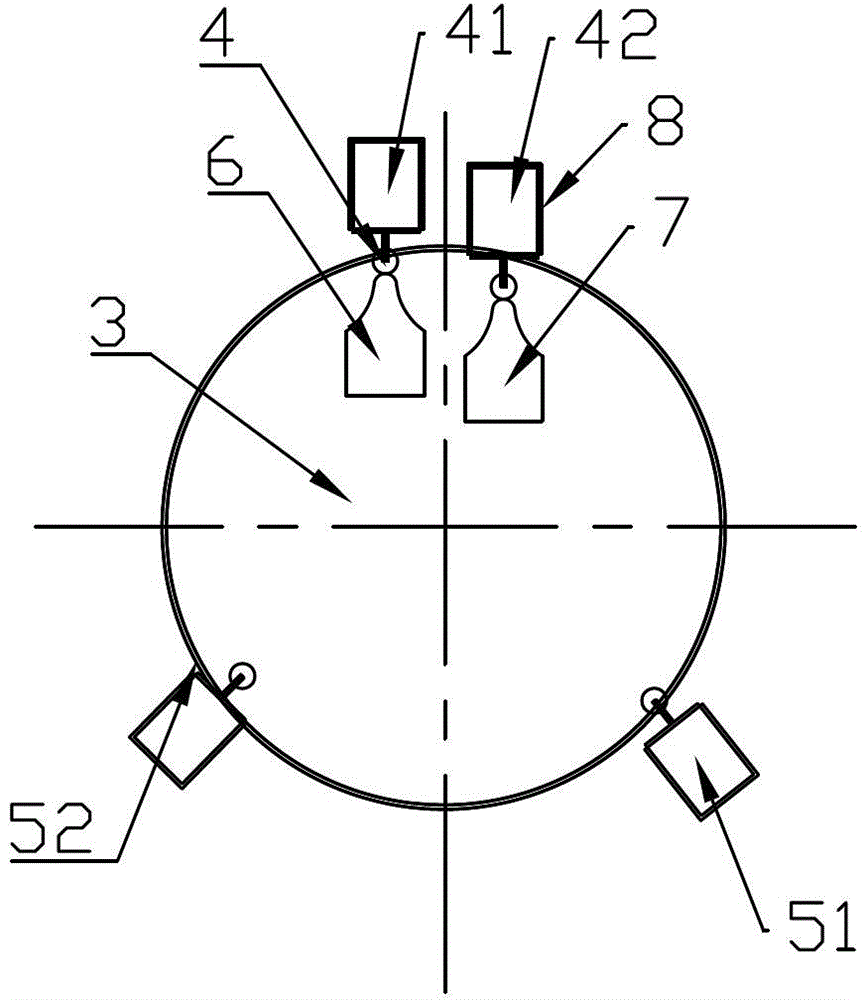

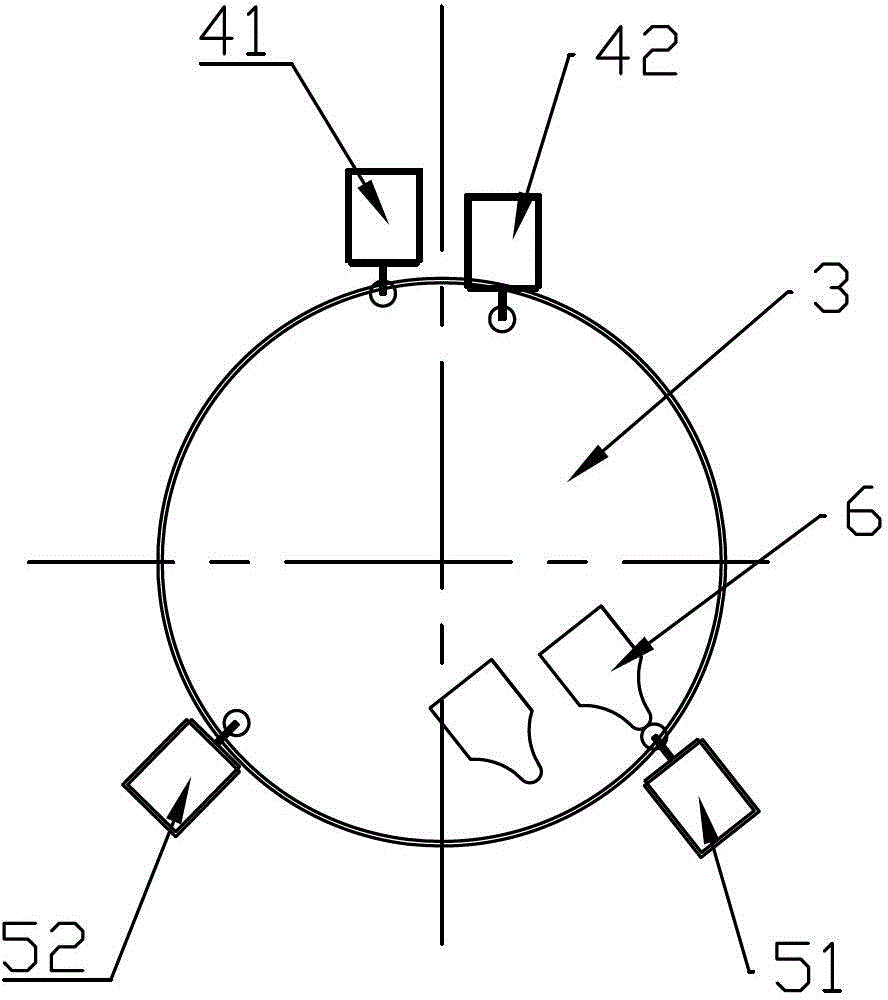

[0016] Such as Figure 1~4 As shown, the present invention provides a torpedo tank with a mechanical limit control system, which includes a torpedo tank body 1 and a tank body driving device 2, and the end of the tank body transmission shaft 3 provided at the end of the torpedo tank body 1 is provided with a vertical The limit device 4 and the left and right tipping limit device 5, the vertical limit device 4 includes a mechanical limit I41 and a mechanical limit II42 and a limit contact I6 corresponding to the mechanical limit I41 and the mechanical limit II42 and limit contact II7; the mechanical limit I41 and mechanical limit II42 are respectively arranged on the steel plate fixing bracket 8 provided outside the tank drive shaft 3, the limit contact I6 and limit co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com