Cutting device

A cutting and knife holder technology, applied in metal processing and other directions, can solve the problems of affecting the use effect, rough bevel lines, complicated process, etc., and achieve the effect of convenient folding, saving time and labor, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

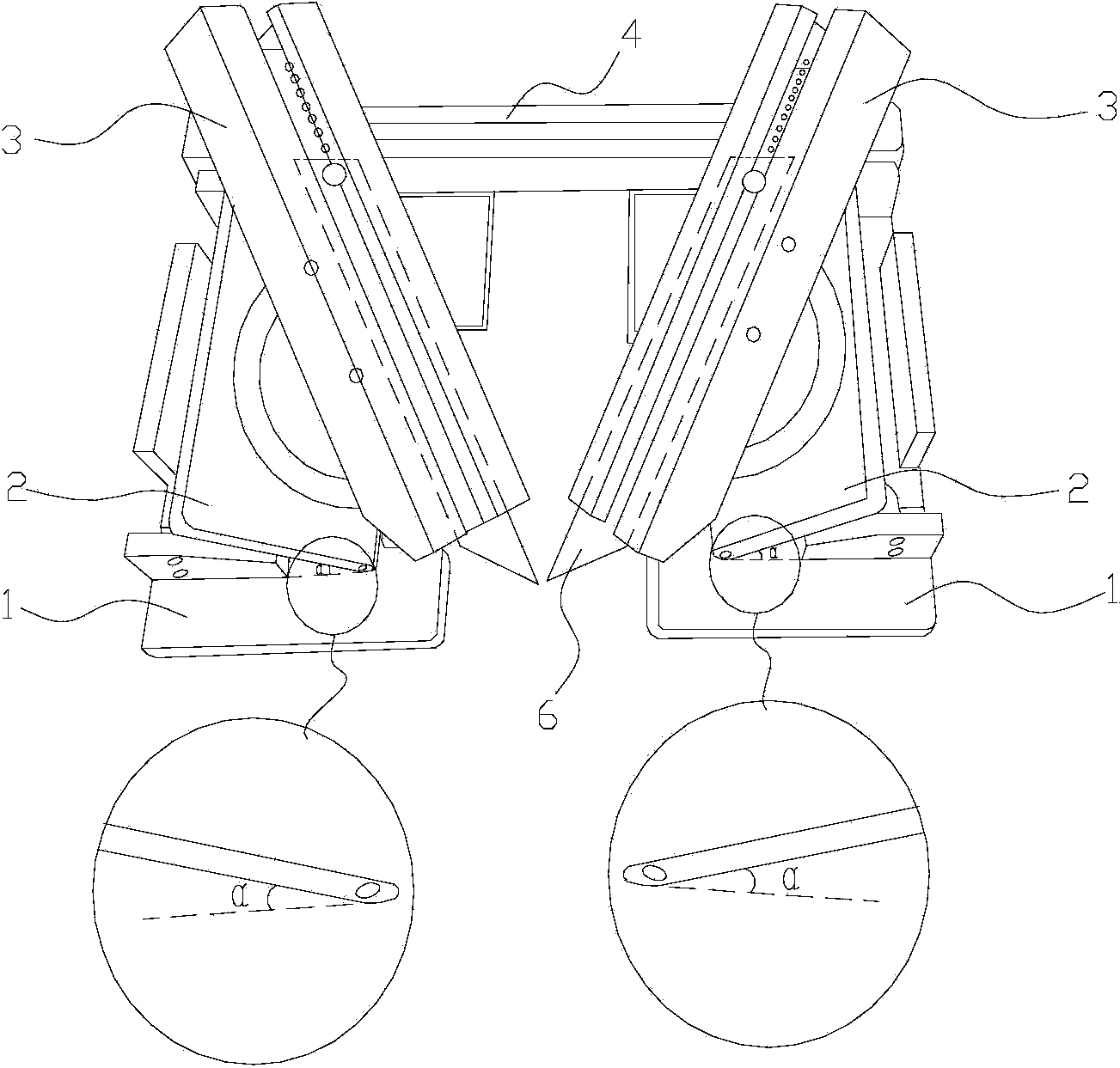

[0027] Attached below figure 1 to attach Figure 13 The present invention is described in further detail.

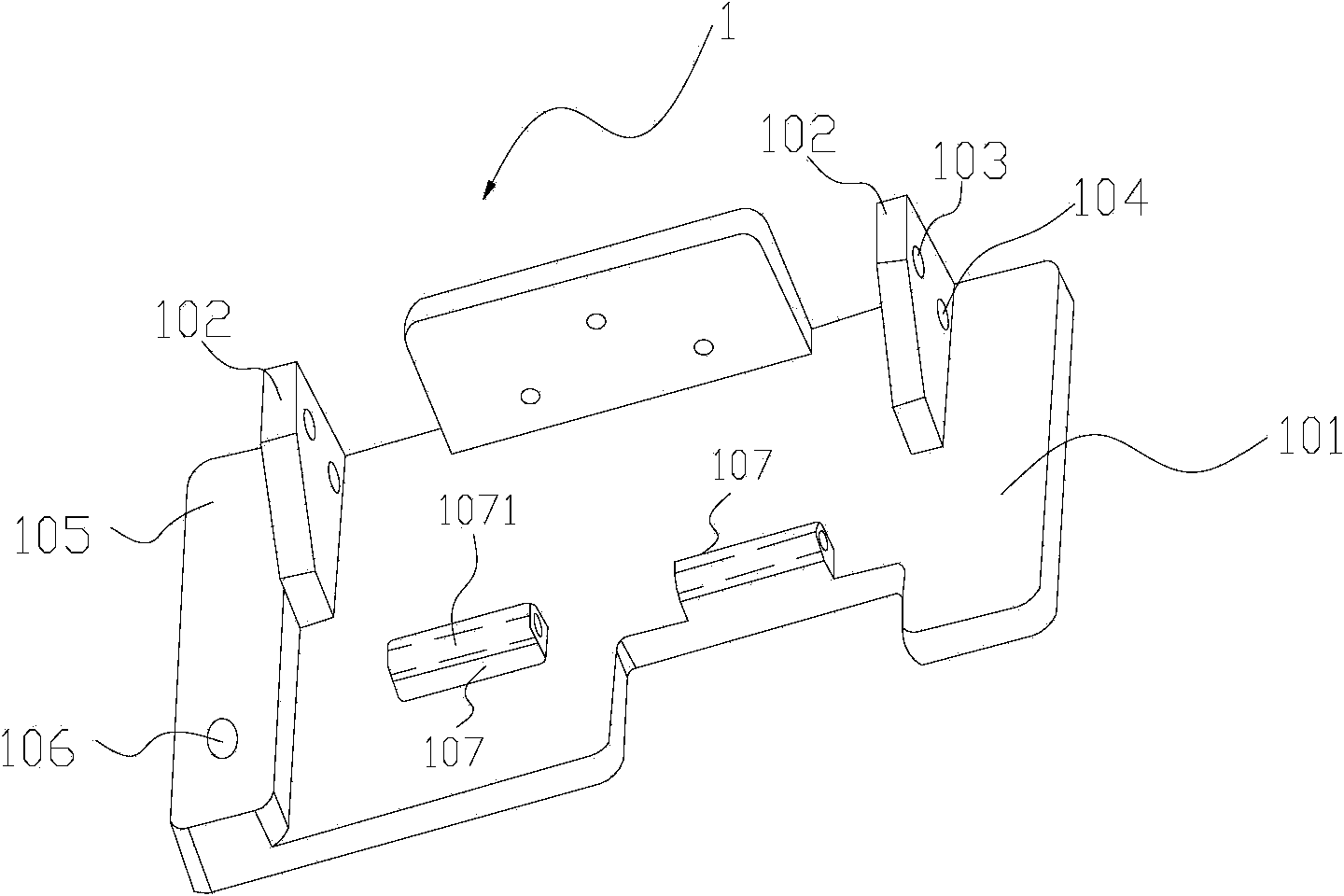

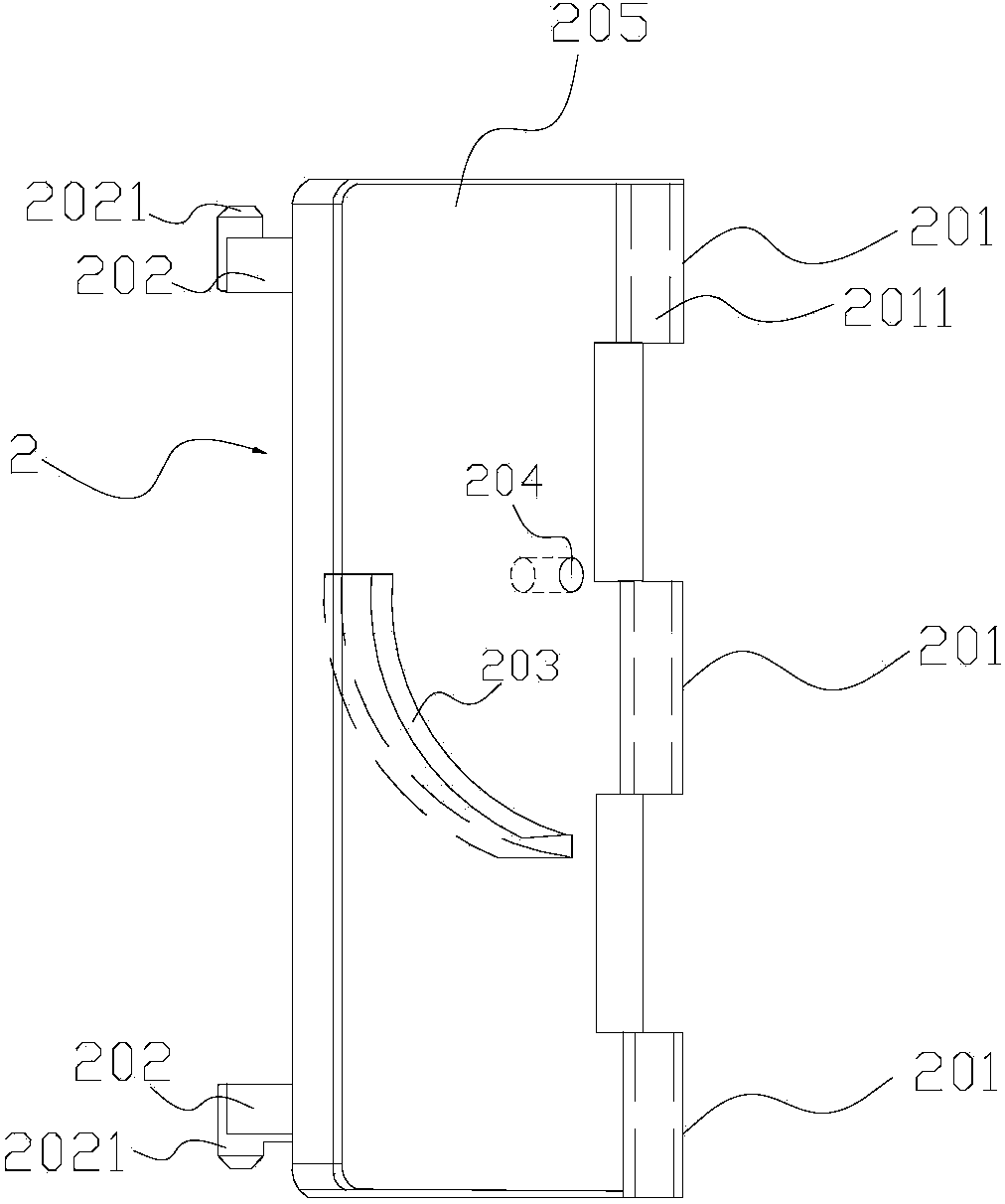

[0028] The cutting device in the present embodiment is placed horizontally, with reference to figure 1 , a cutting device, comprising two left-right symmetrical knife rests and a connecting mechanism 4 connecting the two knife rests. Wherein, the two tool holders are arranged at intervals. Each knife holder may comprise a base 1 , an angle forming member 2 and a knife case 3 . Each angle forming member 2 has an inclined surface, both of which are inclined inwardly, ie both inwardly of the longitudinal edge of the base 1 . The knife case 3 is provided on the slope of the angle forming member 2 . The angle forming member 2 is provided on the base 1 . The degree of inclination of the slope can be represented by the included angle α. Concrete combination figure 1 , figure 2 with image 3 , the sloping plate 205 is the slope of the angle forming member 2 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com