Four-wheel aligner calibrating device based on belt drive

A technology of four-wheel aligner and verification device, which is applied in wheel testing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention is described in detail below in conjunction with accompanying drawing:

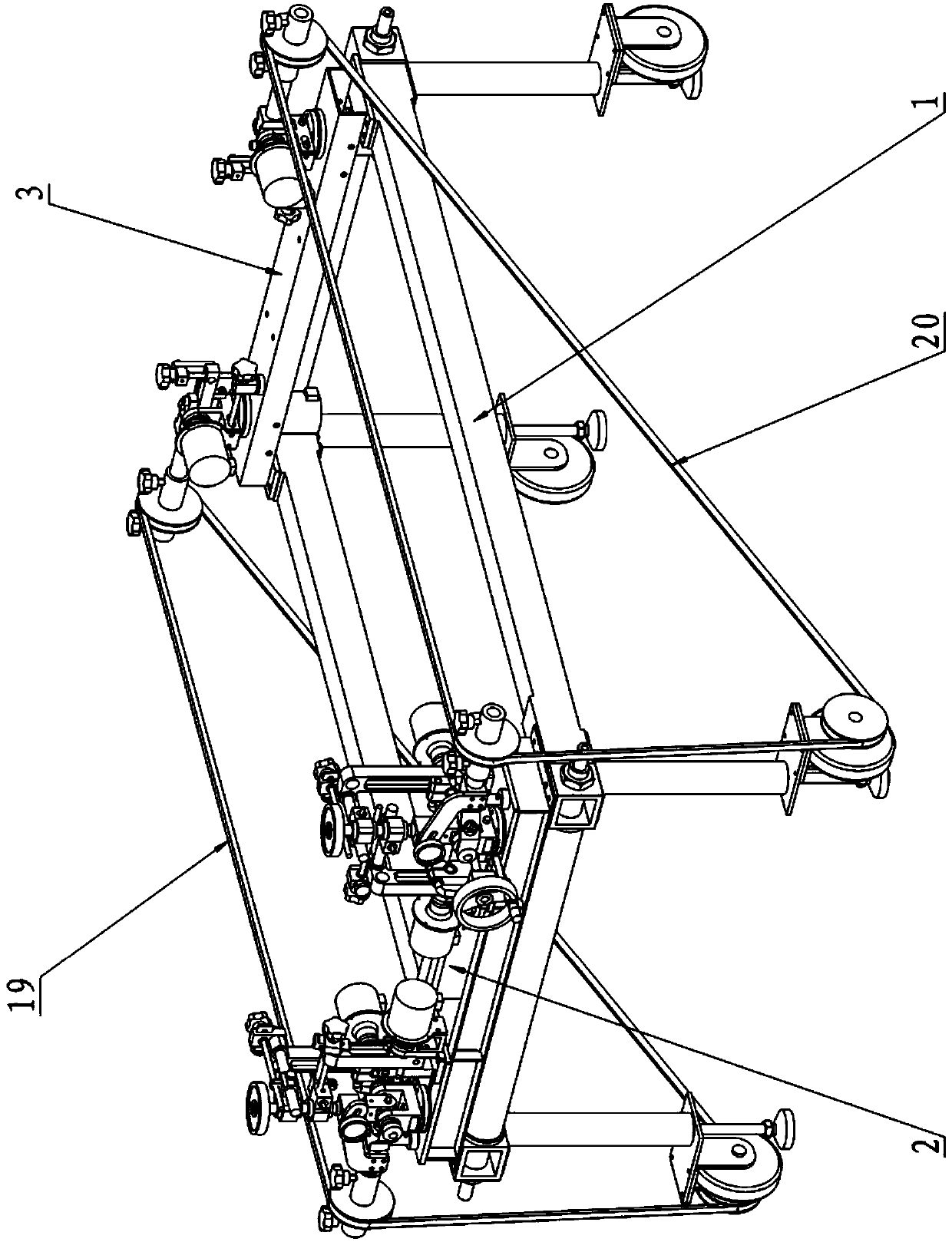

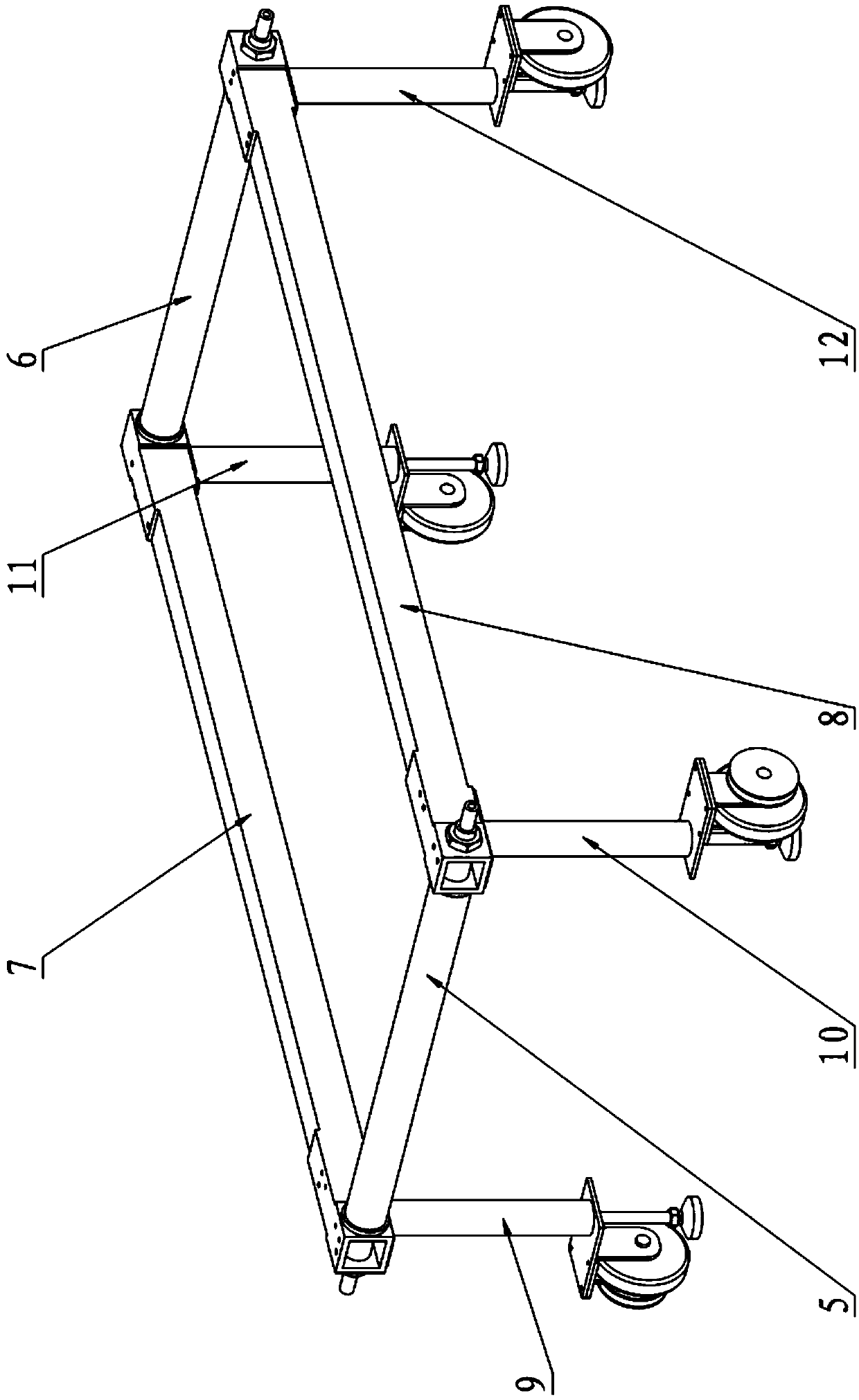

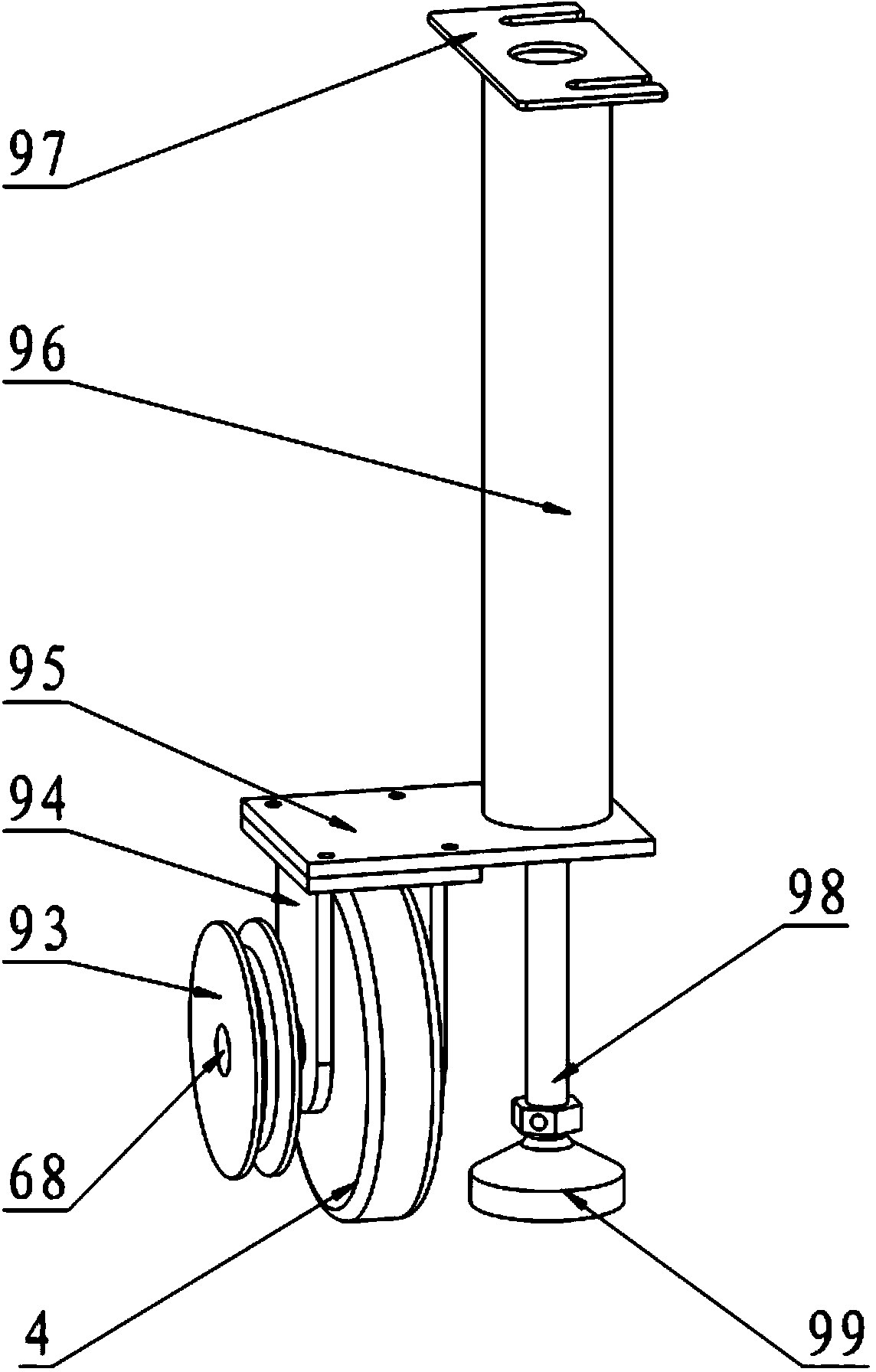

[0068] refer to figure 1 , the verification device based on the belt-driven four-wheel aligner of the present invention is mainly composed of the toe-in zero point inspection frame 1, the front frame inspection part 2, the background frame inspection part 3 and the belt drive (including the right belt drive 19 and the left belt drive 20) composition. The toe-in zero-point inspection frame 1 is used as the installation base of the front-end frame inspection part 2 and the back-end frame inspection part 3 to complete the inspection of the toe-in zero point of the four-wheel aligner; the front-end frame inspection part 2 is installed on the toe-in zero-point inspection frame 1 The right longitudinal beam 7 and the left longitudinal beam 8 are fixedly connected by bolts on the front mounting platform, and the caster angle, kingpin inclination angle, toe-in angle, camber angle and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com