Triaxial coal and gas multi-outbursting test pressure-relief method

A multiple outburst and gas technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problem of large briquette test pieces, which can be as short as a few minutes, as long as more than ten hours, or even a few days; Long test preparation cycle and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

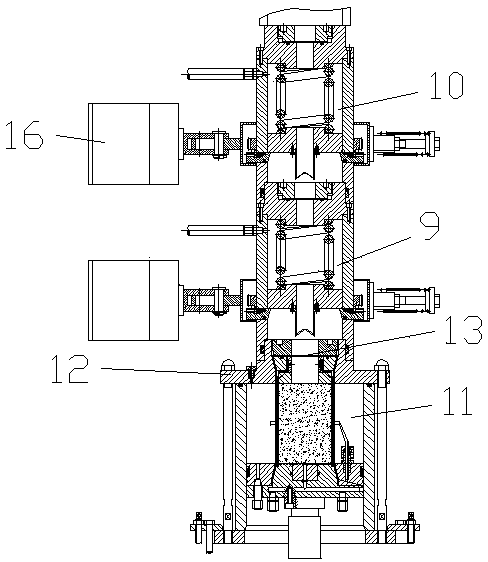

[0023] Triaxial coal and gas multiple outburst test pressure relief method, the first pressure chamber 9 and the second pressure chamber 10 are used in the test pressure relief method.

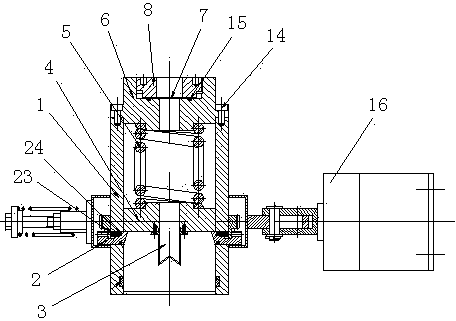

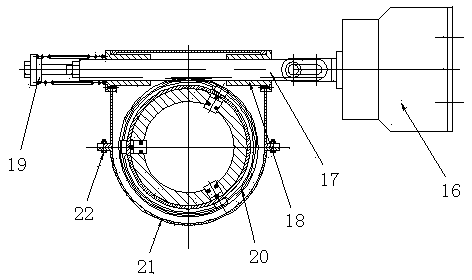

[0024] Both the first pressure chamber 9 and the second pressure chamber 10 include a pressure chamber sleeve 1, a spring locking pin 2, a piercing knife 3, an energy storage spring seat 4, an energy storage spring 5, a top cover 6, and a sealing aluminum sheet 7. The sealing screw plug 8 and the locking pin driving mechanism. At least two through holes are evenly distributed on the circumference of the pressure chamber sleeve 1 (in this embodiment, three through holes are evenly distributed on the circumference of the pressure chamber sleeve 1), and each through hole is provided with a sleeve extending into the pressure chamber. The spring locking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com