Equipment box door and upstream dual-power-circuit-breaker interlocking control mechanism

A technology for circuit breakers and equipment boxes, applied to circuits, electric switches, electrical components, etc., can solve problems such as potential safety hazards, heavy attention burden of control personnel, accidental electric closing of circuit breakers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

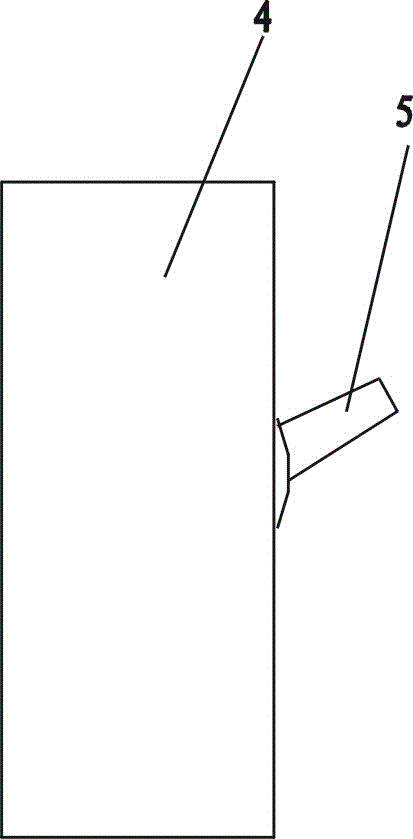

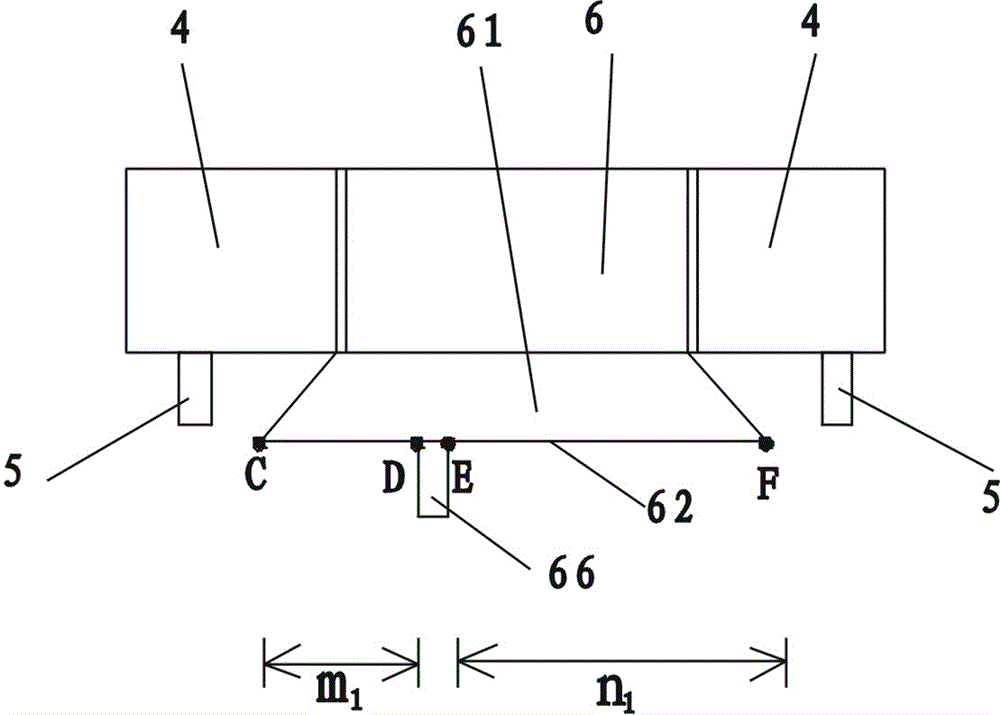

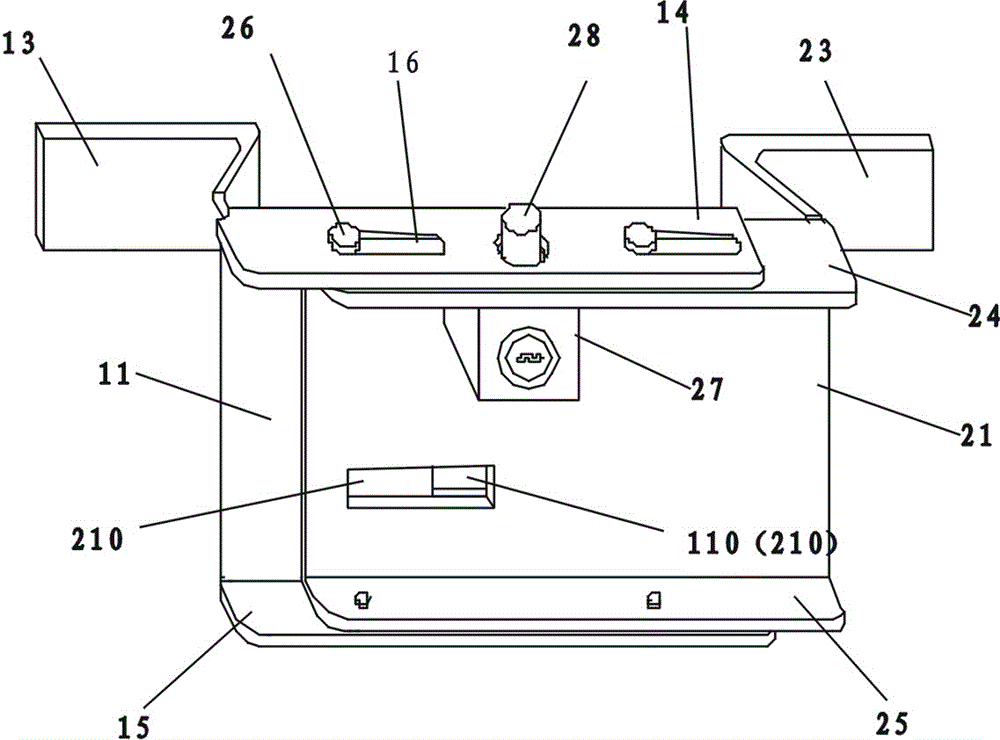

[0047] Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, an equipment box door and an upstream double power supply circuit breaker interlock control mechanism, including an equipment box 7, the equipment box is provided with an equipment box door 71, the equipment box door 71 is provided with a door lock 72, and the door lock 72 is provided with a first lock Core 73 and key 74, the first lock core 73 is provided with the lock key restriction pull-out structure that restricts key 74 to be pulled out under unlocking state; There is a circuit breaker between them, and the two power supplies supply power to the equipment box through the circuit breaker respectively. The power supply relationship is as follows: Figure 6 indicated by the dotted arrow in the middle; Figure 7 , Figure 8 , Figure 10 As shown, a control box 6 is installed between the left and right circuit breakers 4, and each circuit breaker 4 is provided with a control handle 5 that can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com