Large-current resistive load box

A resistive load box and high current technology, applied in the improvement of basic electrical components, etc., can solve problems such as fire, easy-to-burn ceiling, etc., achieve simple and convenient adjustment, solve unreliable contact, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

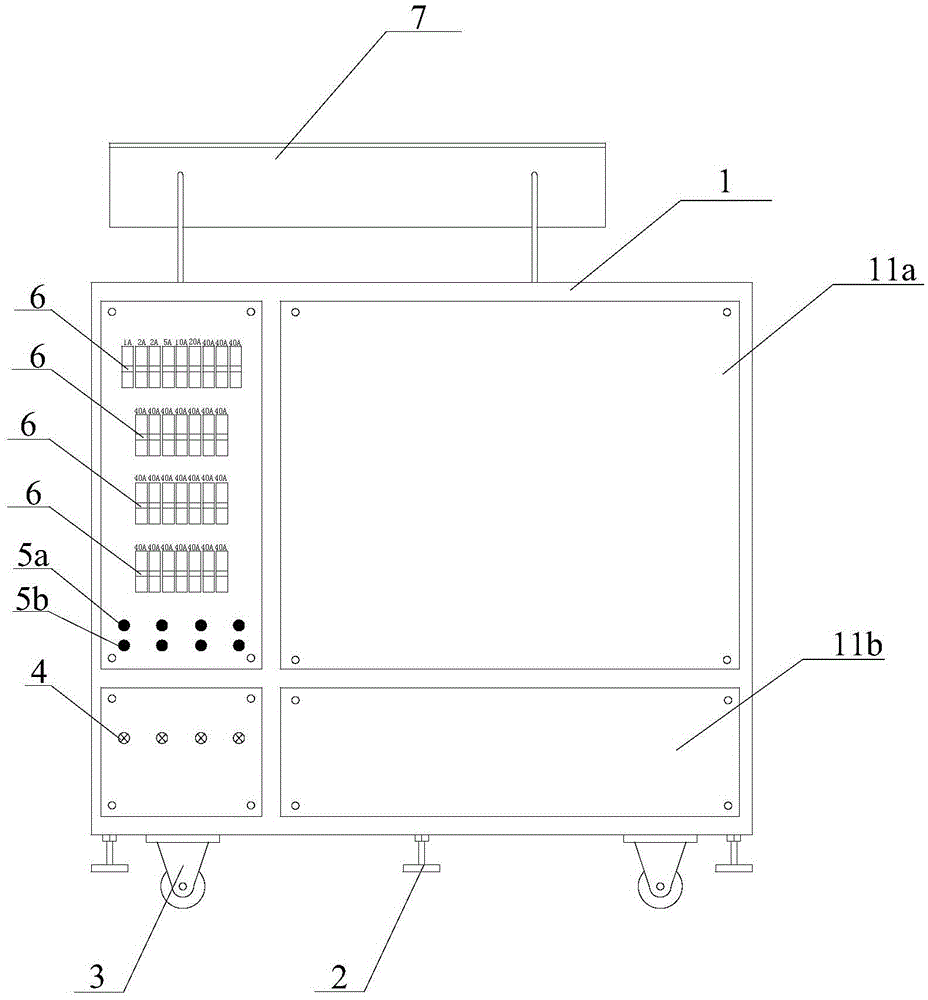

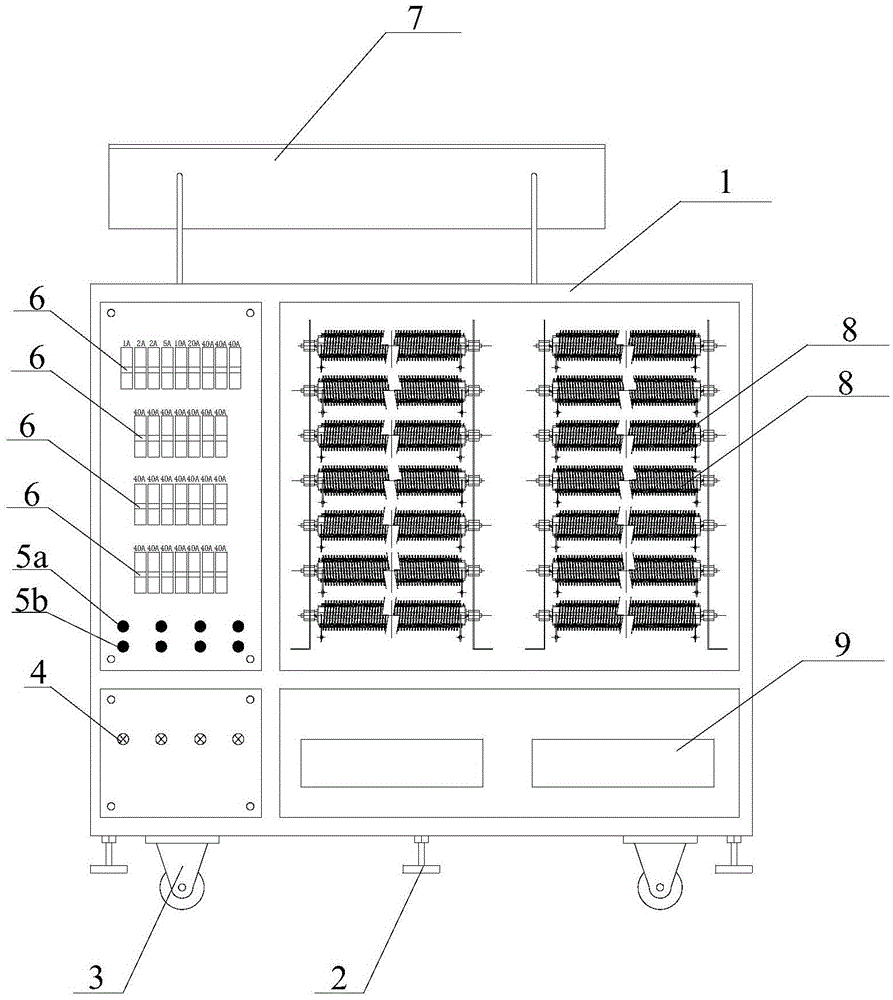

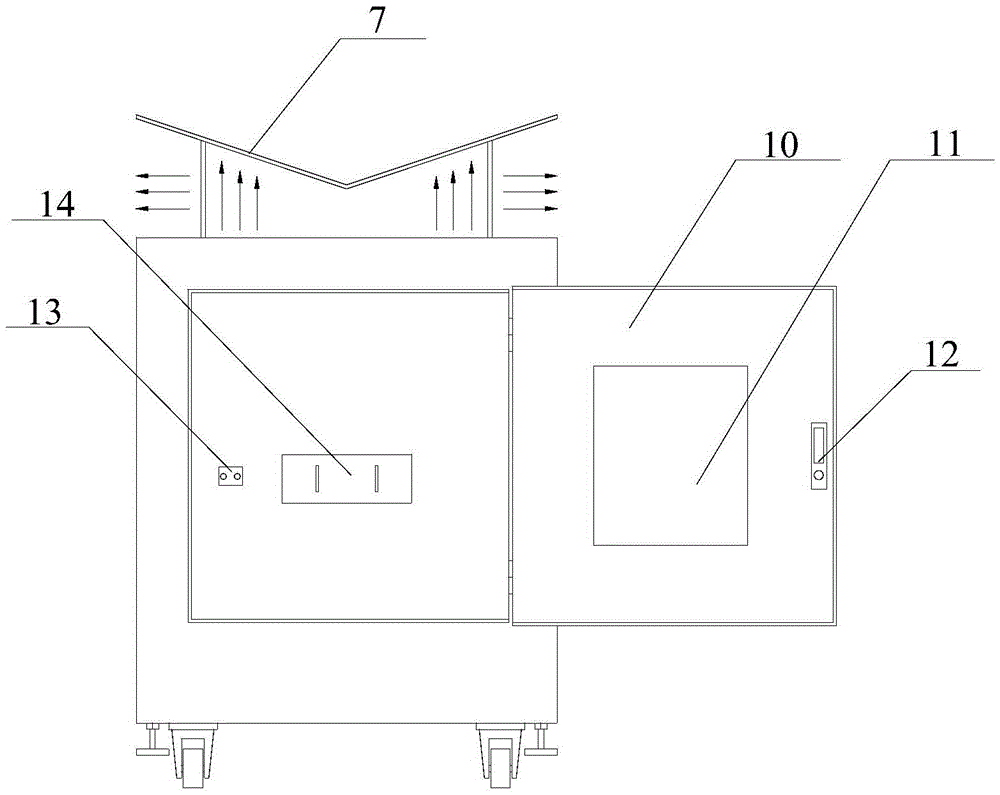

[0018] High-current resistive load box, the load voltage is 270VDC, the total current is 1000A, 1A increments, the maximum current is 1000A, its structure is as follows figure 1 — Figure 5 As shown, it includes a box body 1. The side plates around the box body 1 are steel cold plates, and the upper top plate and the lower bottom plate adopt a mesh structure to prevent debris from entering and facilitate air circulation. The bottom of the box body 1 is equipped with moving wheels 3 and ground feet 2, which are convenient for moving and fixing the large-current resistive load box. The front of the box body 1 is provided with an operation panel and two baffles 11a, 11b, the operation panel and the baffles 11a, 11b are fixed on the box body 1 by four screws at the four corners, and the upper end of the box body 1 has an insulating frame , the insulating fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com