A kind of sintering mold for sealing terminal block

A terminal block and mold technology, which is applied in the assembly/disassembly, connection, circuit/collector parts and other directions of contact pieces, can solve the problems of unqualified sealed terminal blocks, leakage of terminal blocks, low efficiency, etc., and achieve simple design , prevent leakage, improve the effect of qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

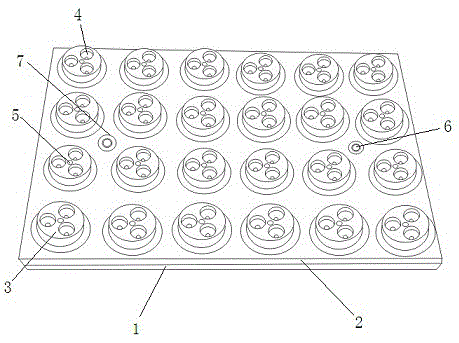

[0015] Such as figure 1 As shown, a sintering mold for sealing a terminal block includes a base plate 1 and a sintering mold plate 2. The shape of the base plate 1 and the sintering mold plate 2 are the same, both of which are rectangular. The base plate 1 and the sintering mold plate 2 are located on the base plate 1 The positioning posts 6 on the top are snapped together, and there are two positioning posts 6, which are symmetrically distributed on the engaging surface of the substrate 1 and the sintering mold plate 2, and the sintering mold plate 2 is provided with a positioning hole 7 corresponding to the positioning post 6, The substrate 1 can be placed in the sintering furnace after the sintering mold is placed. Even if it shakes, it can ensure that the terminal does not leak from the glass column placement hole in the sintering mold, which improves the product q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com