Wireless receiver automatic assembly equipment

A wireless receiver and automatic assembly technology, which is applied in assembly machines, metal processing equipment, metal processing, etc., can solve the problems of low production efficiency and incomplete automation, and achieve the goals of improving use efficiency, optimizing layout, and reducing floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

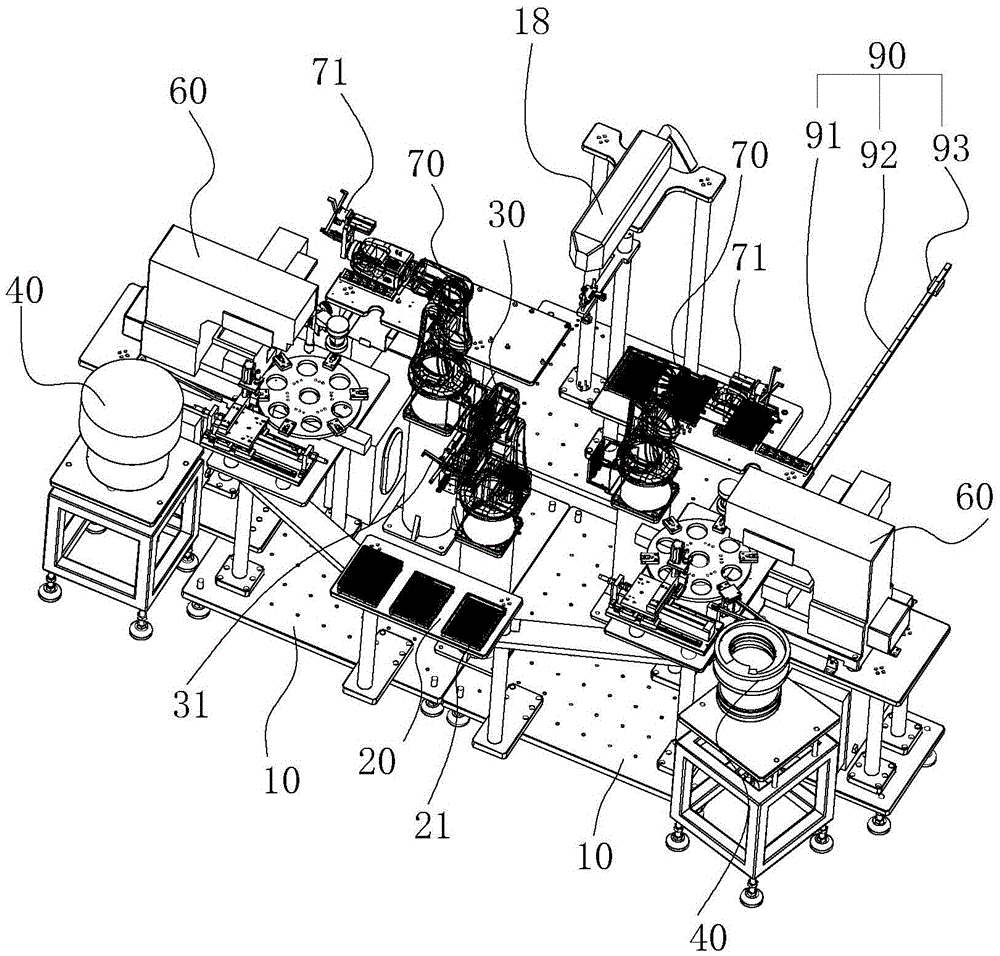

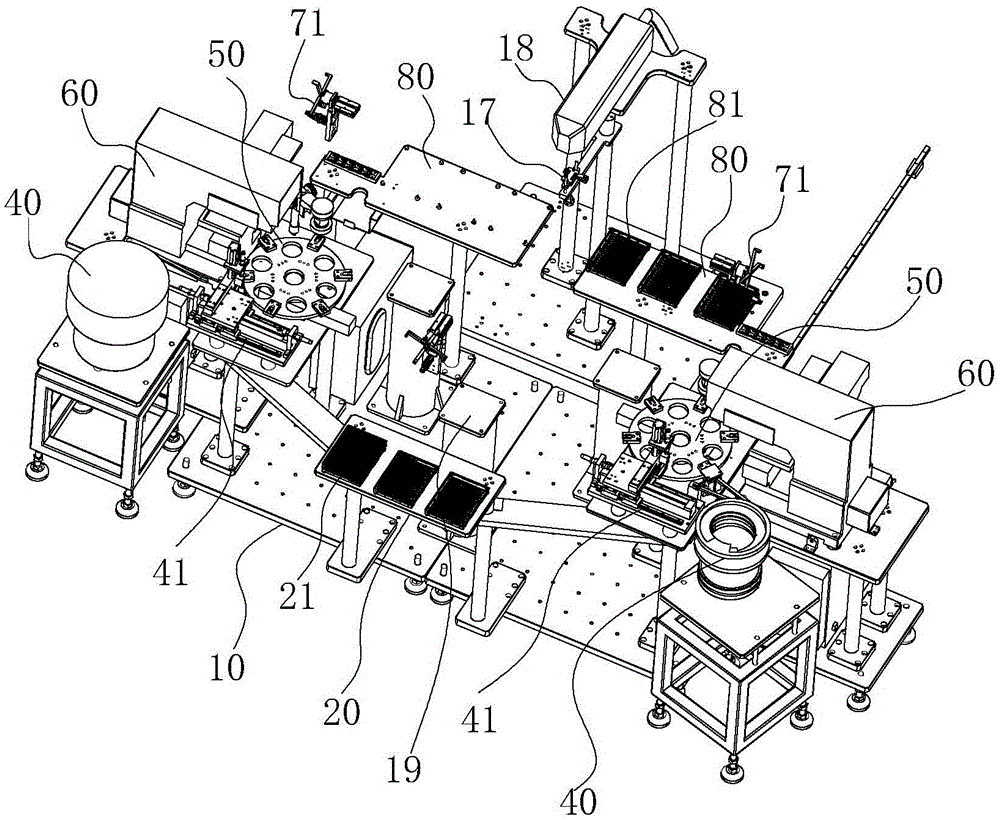

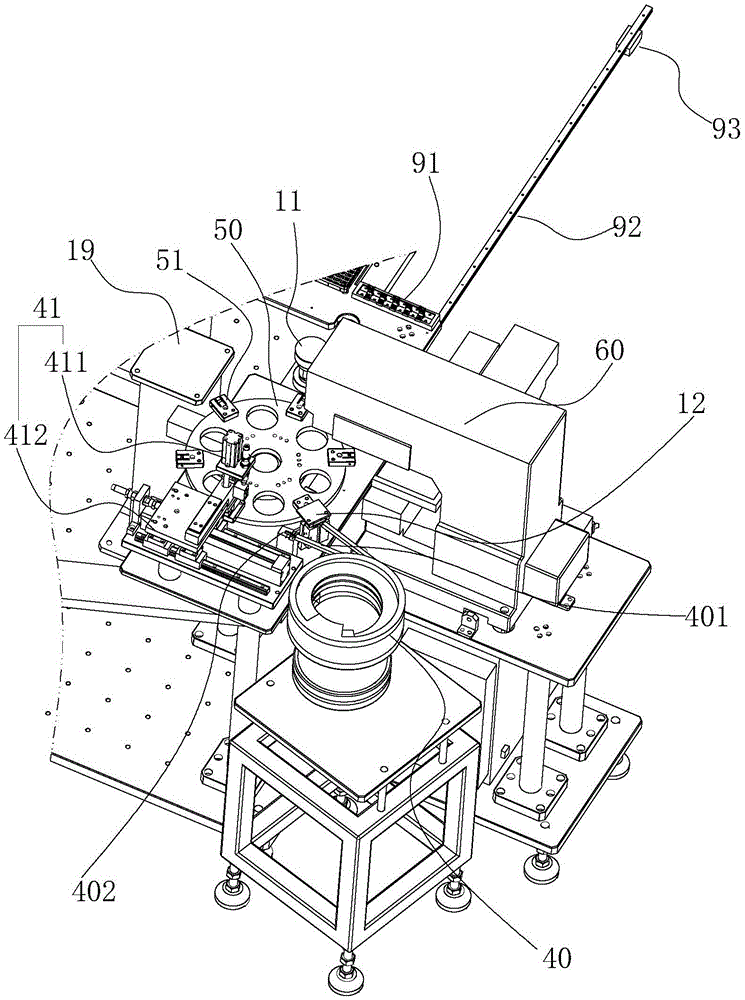

[0051] Such as Figure 1-Figure 5 As shown, the wireless receiver automatic assembly equipment of the present invention includes the following major components:

[0052] The base 10 plays the role of support and fixed connection, and fixes the major components together; the base 10 is provided with a visual sensor 11, and the visual sensor 11 corresponds to the visual detection station of the turntable, and controls the printing characters on the back cover. Carry out testing to judge whether characters such as pad-printed LOGO are up to standard.

[0053] The shell feeding platform 20 is fixed on the base 10 and is provided with a plurality of shell magazines 21 for providing shells. In this embodiment, the turntable worktables on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com