Electronic cigarette assembling equipment

A technology for assembling equipment and electronic cigarettes, which is applied in the direction of assembly machines, metal processing equipment, tobacco, etc., can solve the problems of difficult assembly quality assurance, high assembly cost, and poor product uniformity, so as to improve assembly efficiency, have more stations, and realize The effect of fully automatic installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

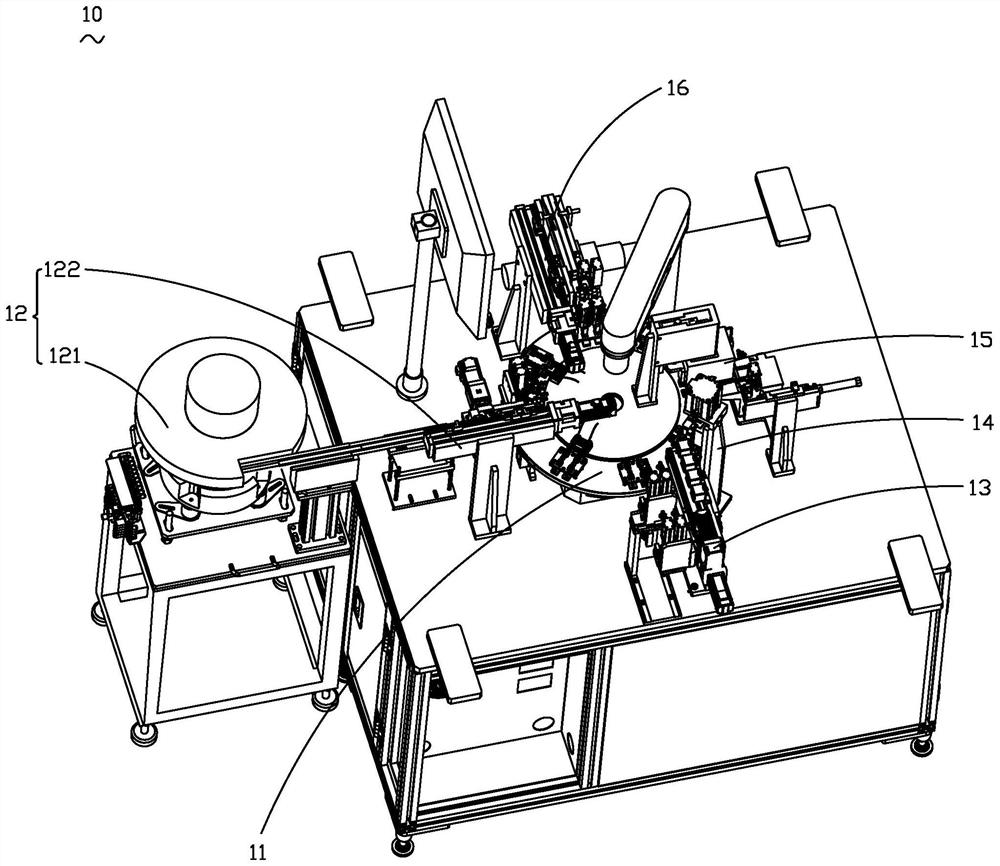

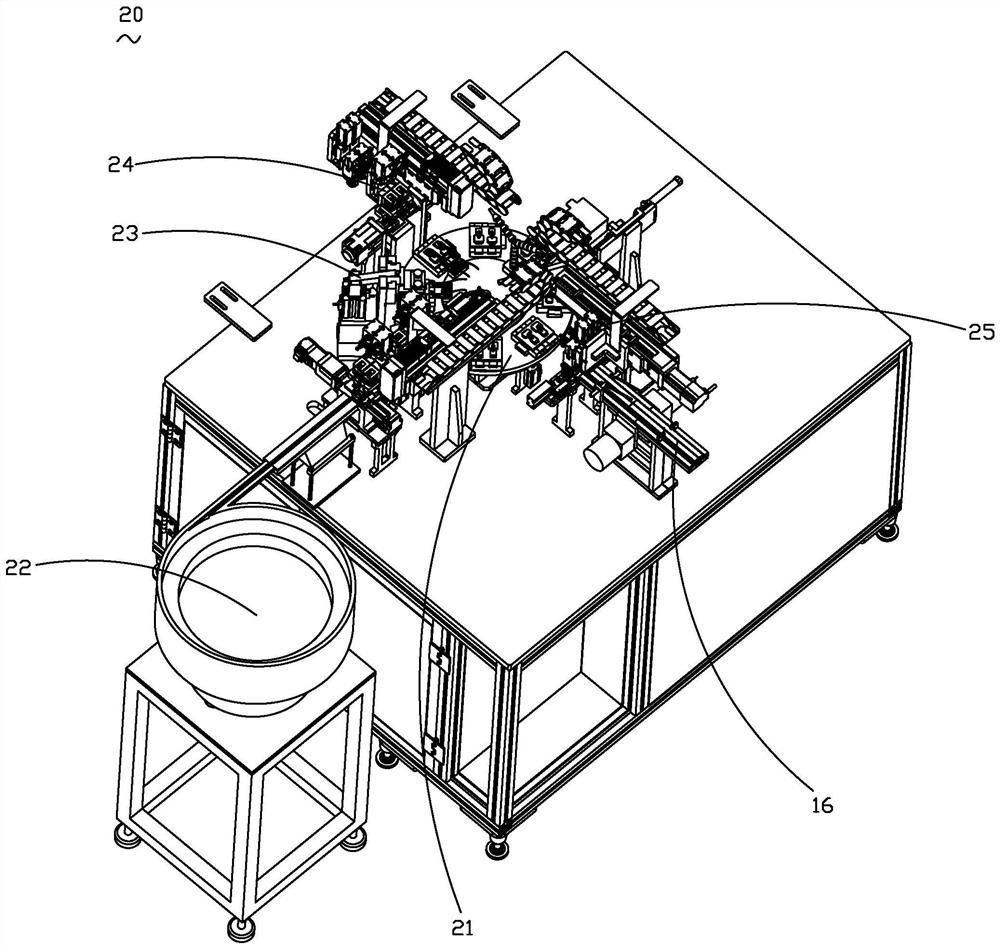

[0043] Embodiment 1: as Figures 1 to 10 As shown, the e-cigarette assembly equipment of this embodiment includes a machine frame, and a pod bracket installation station 10 and an atomizing core base installation station 20 arranged on the machine frame.

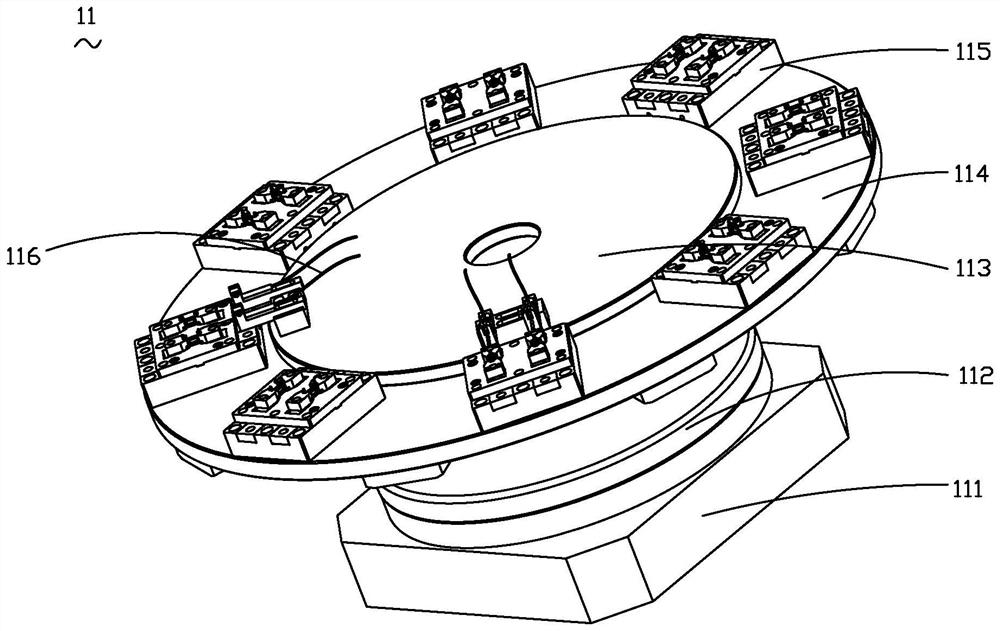

[0044] The pod holder installation station 10 is used to assemble the first assembly and the pod holder 4 to form a second assembly, which specifically includes a bracket turntable assembly 11 and a bracket feeding device respectively arranged on the periphery of the bracket turntable assembly 11 12. The first assembly transfer device 13, the bracket riveting device 14, the second assembly defective product detection device 15 and the second assembly discharge device 16; the bracket turntable assembly 11 is used to carry the parts to be assembled, And transport the parts to be assembled to the next station by rotating; the first assembly transfer device 13 is used to transfer the first assembly to the pod holder on the brack...

Embodiment 2

[0058] Embodiment 2: On the basis of Embodiment 1, the electronic cigarette assembly equipment of this embodiment may also include a ceramic atomizing core seal installation station, a pod holder seal installation station, an oil cup installation station, and auxiliary parts Install the workstation to realize the fully automated operation of e-cigarette assembly, improve assembly efficiency and assembly accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com