Fuel filler neck provided with an attachment device

A technology for fastening devices and fuel filling, which is applied to power devices, arrangements combined with internal combustion engine fuel supply, hoses, etc., and can solve problems such as being unable to maintain positions independently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

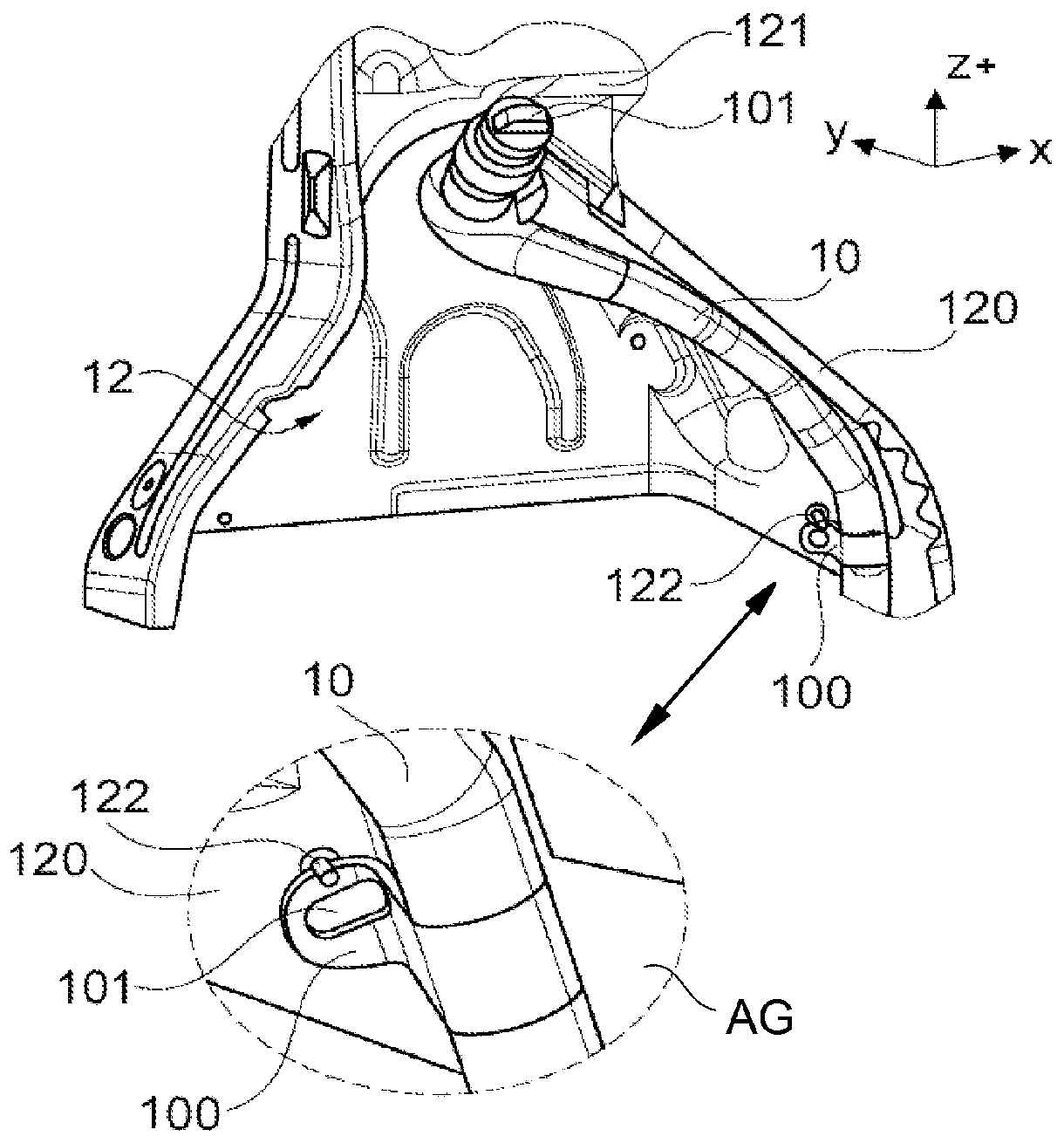

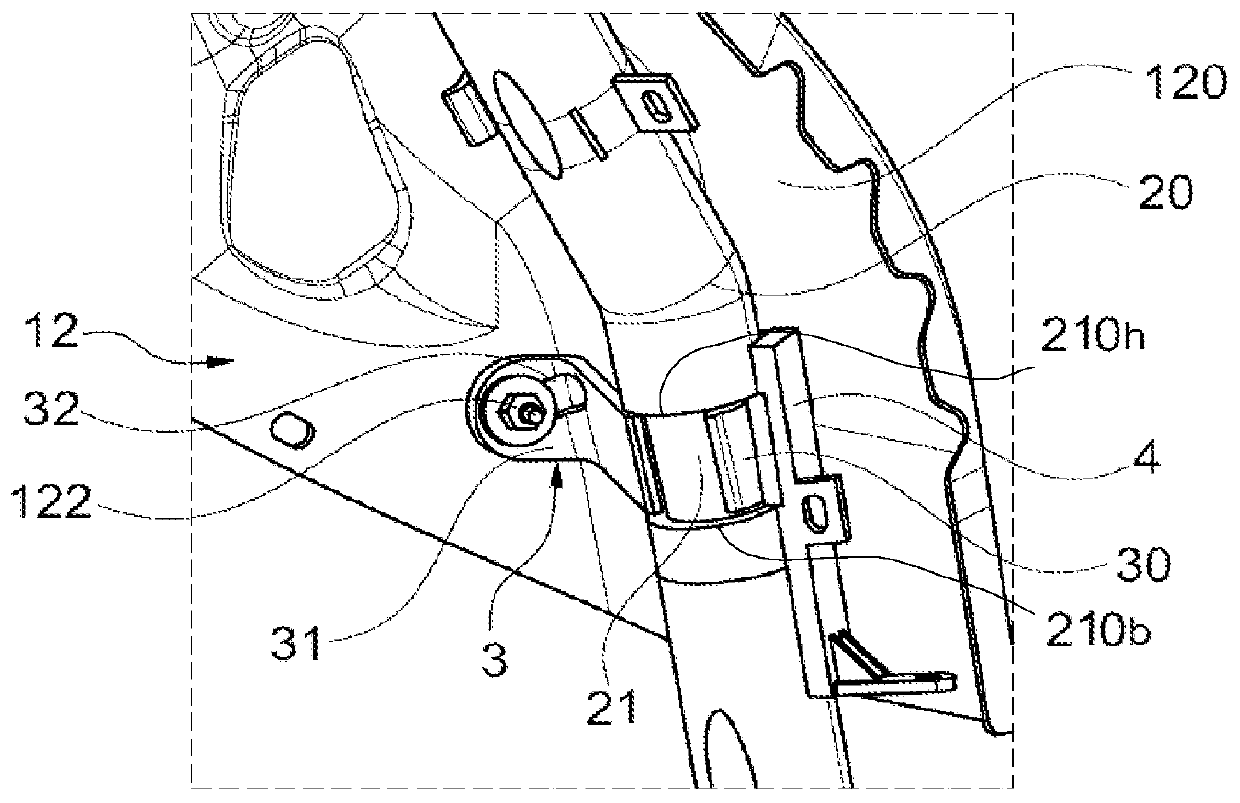

[0021] refer to Figure 2 to Figure 4 as well as Figure 5A , Figure 5B , a specific embodiment 20 of the fuel filler pipe according to the invention, and its fastening in the wheel arch 12 will now be described.

[0022] The fuel filler pipe 20 is usually a part made of plastic and comprises a pivotable fastening claw 3 . The pivotable fastening pawl 3 is mounted in a rigid or semi-rigid part of the tube 20 . More specifically, in this particular example, as figure 2 As shown, the fastening pawl 3 is pivotally mounted on a portion 21 of the tube 20 forming a rotational support. The rotational support part 21 is a cylindrical part, which here has an outer diameter which is smaller than the outer diameter of the tube. The swivel support portion 21 is delimited in height by two opposing annular shoulders 210h, 210b to prevent translation of the pivotable fastening pawl 3 .

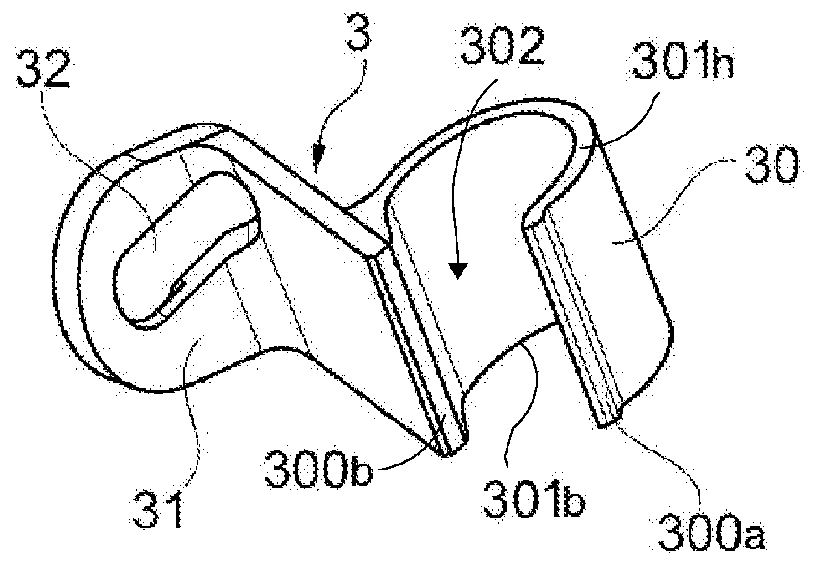

[0023] Such as image 3 As shown, the pivotable fastening claw 3 mainly includes a ring member 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com