AGV used for automatic assembling

An automatic assembly and trolley technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as error-prone, incomplete positioning, and missing screws, so as to improve quality, accurate feeding process, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

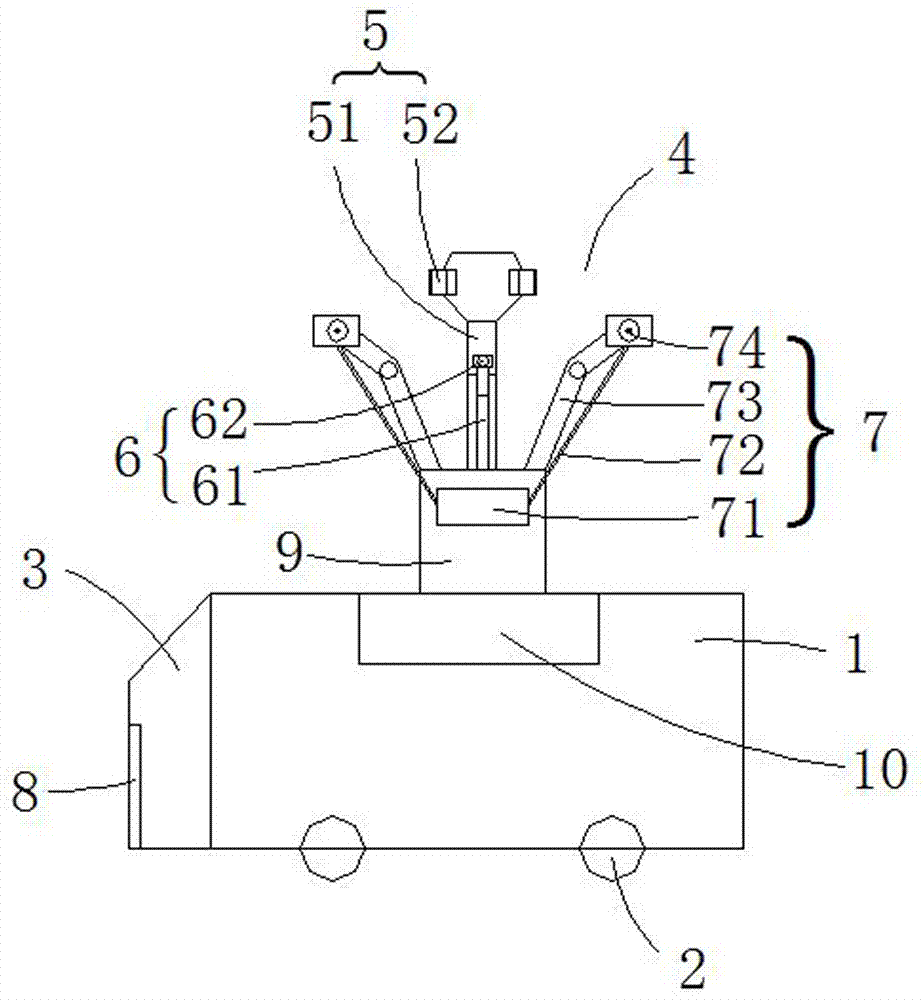

[0022] A kind of AGV dolly for automatic assembly of the present invention, as figure 1 As shown, it includes a vehicle body 1, a roller 2 arranged under the vehicle body 1, an automatic guiding system 3 arranged in the vehicle body 1, and an automatic assembly system 4 arranged above the vehicle body 1; the automatic assembly system 4 includes a clamping device 5. The positioning detection device 6 and the screw installation device 7; the clamping device 5 includes a first mechanical arm 51 and a pair of jaws 52 arranged at the end of the first mechanical arm 51; the positioning detection device 6 includes a second The mechanical arm 61 and the induction device 62 arranged at the end of the second mechanical arm 61; the screw installation device 7 includes a screw storage device 71, a screw delivery device 72, a pair of third mechanical arms arranged on both sides of the first mechanical arm 51 arm 73, and a screw installation head 74 arranged at the end of the third mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com