Inversely assembled type bearing seat of press machine

A bearing seat and press technology, applied in the field of mechanical presses, can solve the problems of inability to adjust the bearing clearance, abnormal operation of the press, inconvenient space layout, etc., and achieve the effect of convenient adjustment, convenient bearing clearance, and overall quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

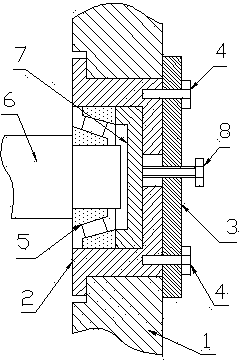

[0010] In the figure, this type of reverse-mounted bearing seat of a press includes a machine body 1, a bearing seat 2, an end cover 3, a fastening screw 4, a bearing 5, a gear shaft 6, an adjusting sleeve 7, and an adjusting screw 8. The reverse-mounted bearing of the press is installed in the hole on the side of the machine body 1, and the bearing seat 2 is installed and fixed through the fastening screw 4 and the end cover 3. The bearing 5 is installed in the inner hole of the bearing seat 2, and the bearing 5 is installed in the inner hole. There is a gear shaft 6, and an adjusting sleeve 7 is fixed in the inner hole of the bearing seat 2. The outer circle of the adjusting sleeve 7 is close to the outer circle of the bearing 5, and a fixed sleeve is fixed at the center of the end cover 3 An adjustment screw 8 , the head of the adjustment screw 8 fits the adjustment sleeve 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com