Car rim and spinning process thereof

A spinning process and rim technology, which is applied to rims, vehicle parts, transportation and packaging, etc., can solve the problems of insufficient strength of automobile rims, heavy weight of automobile rims, and large driving resistance, etc., to achieve light weight, meet driving requirements, reduce The effect of driving resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

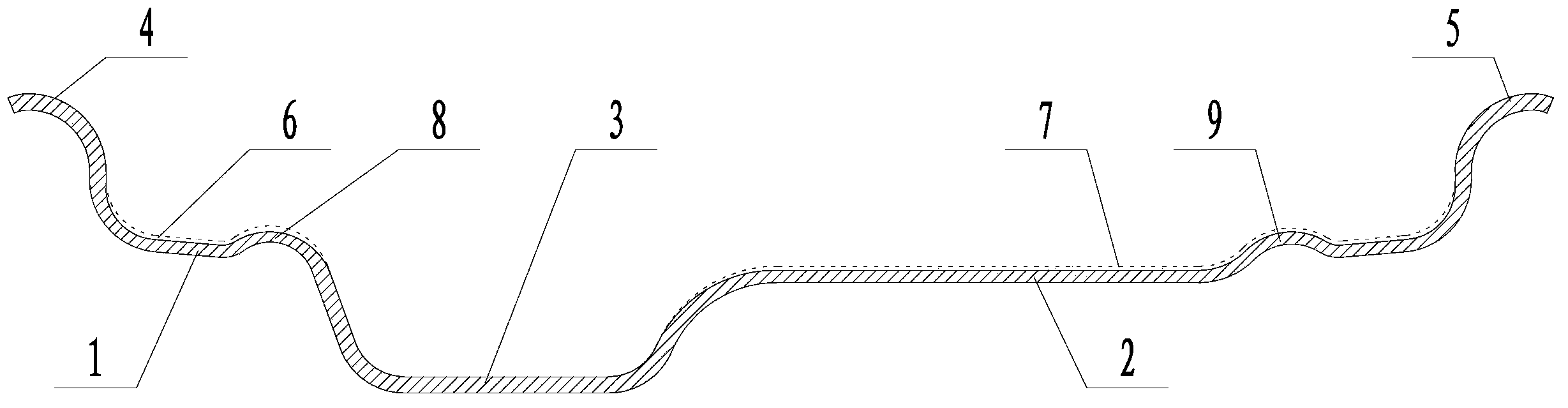

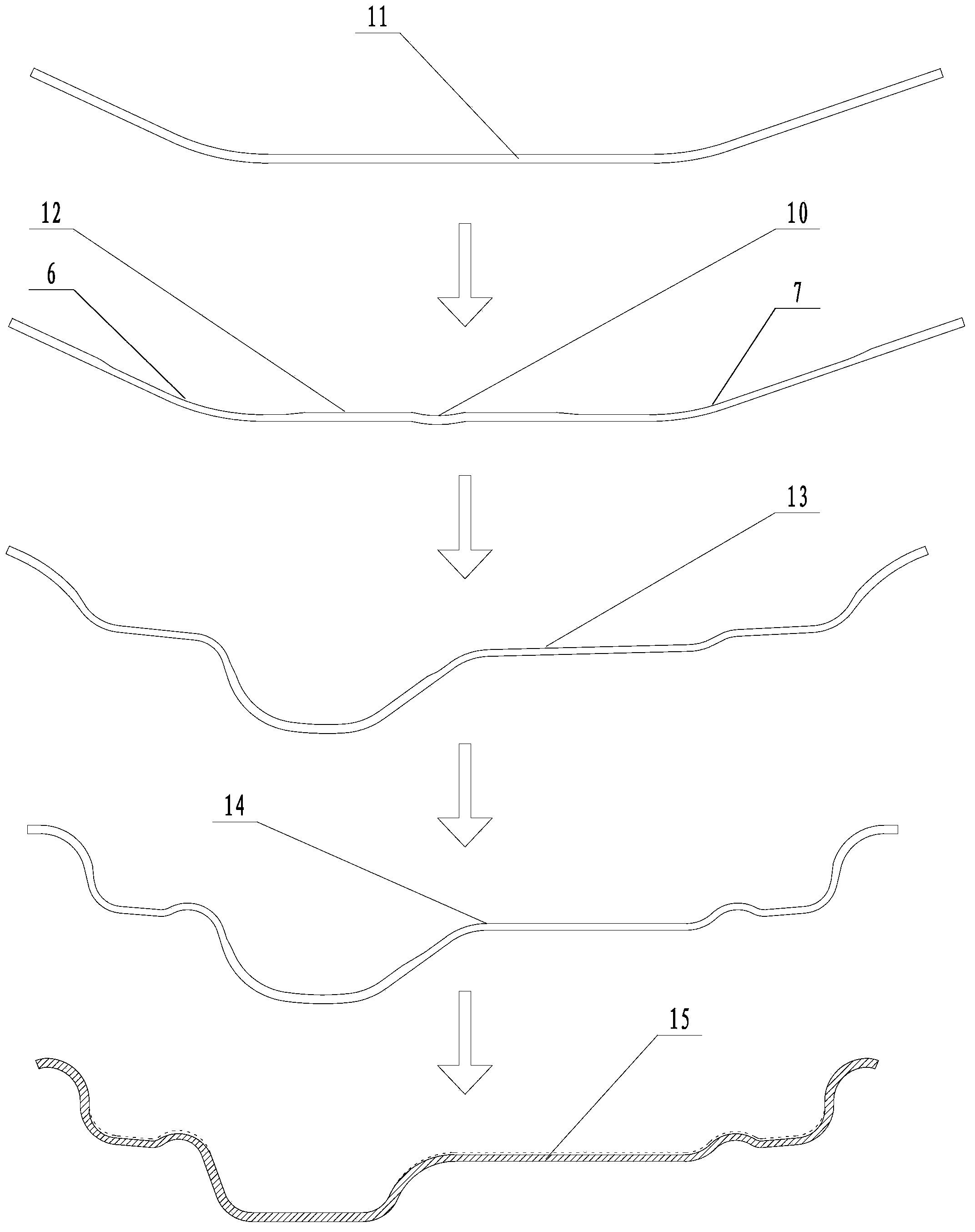

[0029] Embodiment: a kind of automobile rim (referring to attached figure 1 ), including the outer bead seat 1, the inner bead seat 2, the bottom groove 3 arranged between the inner bead seat and the outer bead seat, the outer rim 4 connected to the end of the outer bead seat, and the bottom groove connected to the end of the inner bead seat The inner rim 5, the outer bead seat serves as a short shoulder bead seat, and the inner bead seat serves as a long shoulder bead seat. The outer surfaces of the outer bead seat and the inner bead seat are respectively provided with an outer spinning area 6 and an inner spinning area 7, and the outer spinning area extends from the connection position between the outer bead seat and the outer rim to the connection between the outer bead seat and the bottom groove Position, the inner spinning area extends from the connection position between the inner bead seat and the inner rim to the connection position between the inner bead seat and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com