Novel despooling device

A pay-off device, a new type of technology, applied in the field of pay-off devices, can solve the problems of affecting work efficiency, high price, laborious aluminum core wire, etc., and achieve the effect of improving work efficiency, good mechanical stability and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

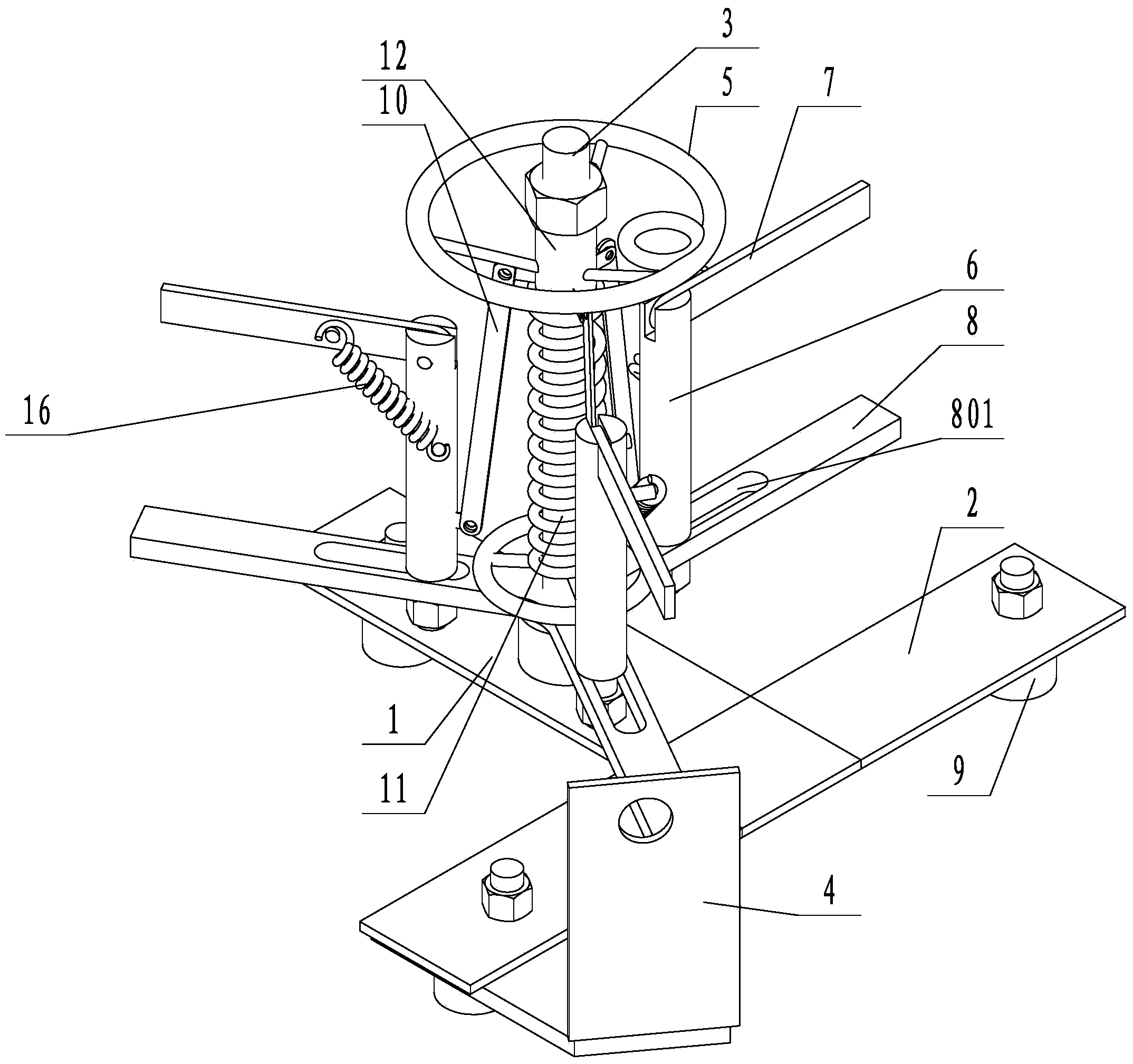

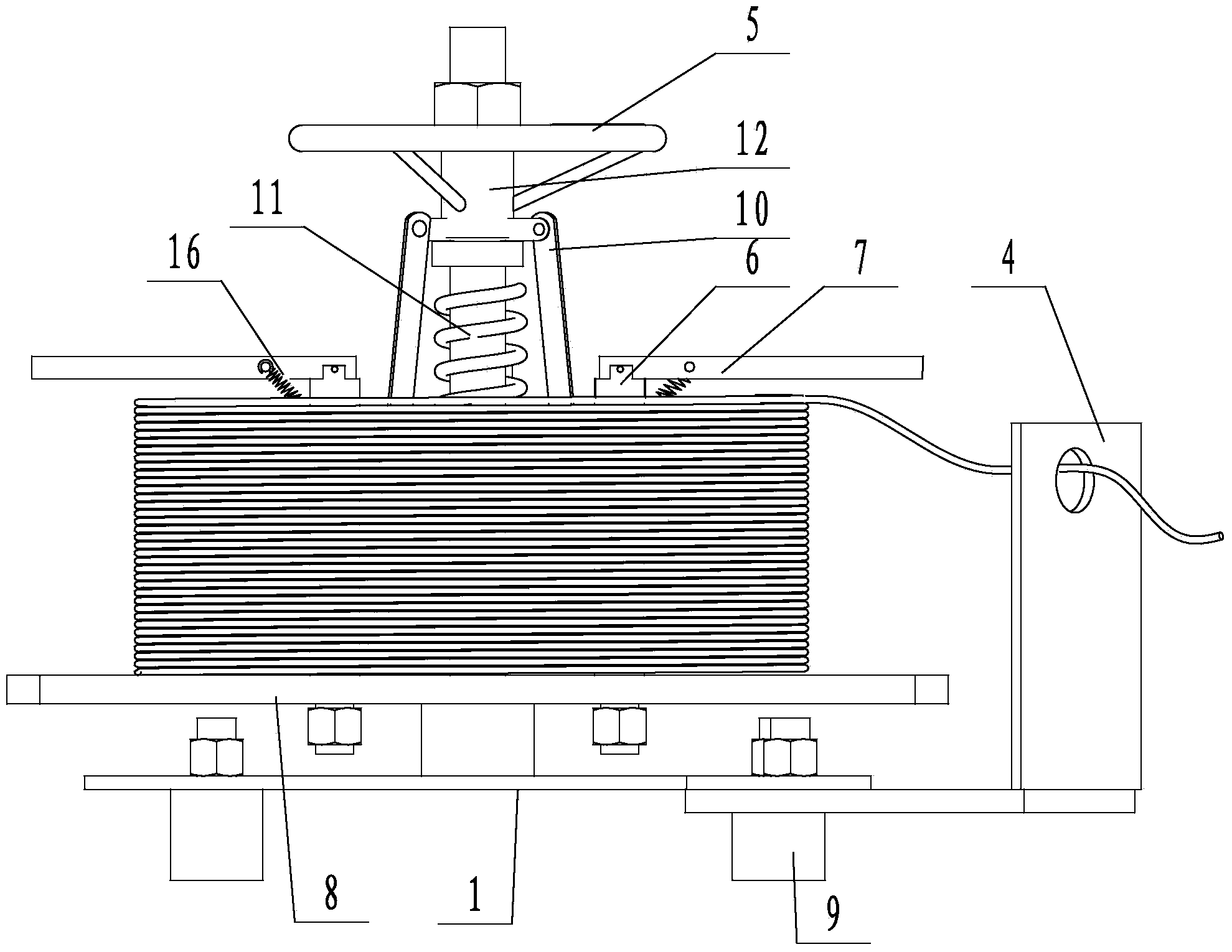

[0029] like figure 1 As shown, the present invention includes a base, a vertical shaft 3 arranged in the middle of the base, a guide frame 4 arranged on the base, a turntable connected in rotation with the vertical shaft 3, a hand plate 5 arranged above the turntable, and a plurality of evenly arranged spacers on the circumference. Frame; the middle part of the guide frame 4 is provided with a threading hole; the limit frame is detachably connected vertically on the turntable, and the turntable is provided with a plurality of waist-shaped grooves 801, and the limit frame can The groove 801 moves radially to adjust the radial size to meet the multi-standard reels; the limit frame includes a vertical rod 6 and a height limit rod 7, and the lower end of the vertical rod 6 is provided with external threads, and the lower end of the vertical rod 6 It is inserted into the waist-shaped groove and fixedly connected to the turntable through nuts; the vertical rod 6 is movably connected...

Embodiment 2

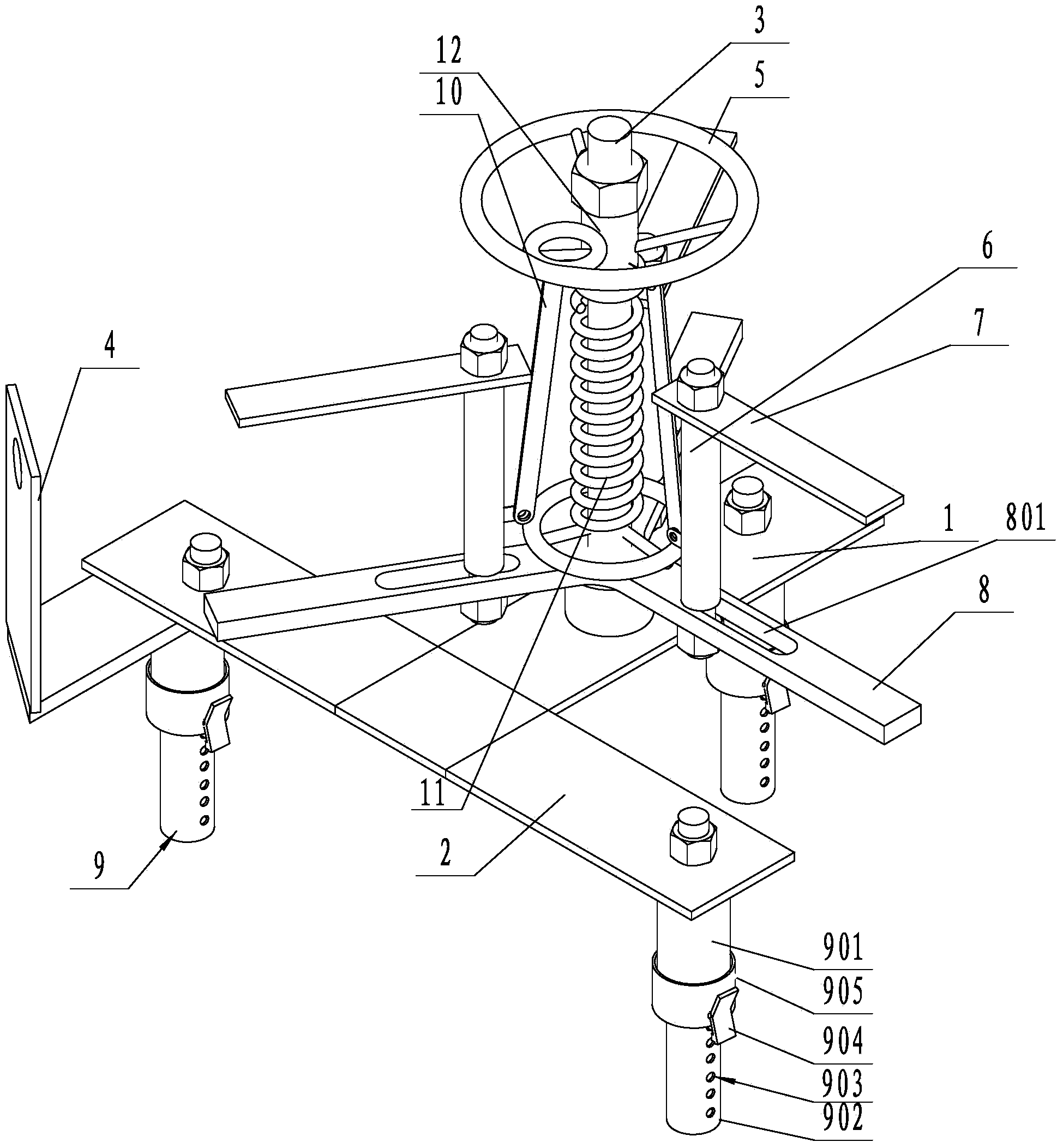

[0033] To adapt to different ground, especially slopes, or other uneven ground. like image 3 As shown, the difference from the first embodiment is that three height-adjustable legs 9 are provided under the base. The adjustable supporting foot 9 can be in the form of a screw, and the length of the screw can be determined by the rotation of the screw, or the adjustment of the length can be realized by connecting the sleeves one by one. In this embodiment, the support foot 9 includes an outer cylinder 901, an inner cylinder 902, and a positioning mechanism provided on the outer cylinder 901. The outer cylinder 901 is fixedly connected to the turntable, and the outer cylinder 901 is overlaid on the inner cylinder 902. , the outer cylinder 901 and the inner cylinder 902 have a clearance fit, the inner wall of the outer cylinder 901 is provided with at least one axial guide groove, the outer wall of the inner cylinder 902 is provided with a guide bar matching the guide groove of t...

Embodiment 3

[0035] To accommodate different reel sizes, such as Figure 4 As shown, the difference from Embodiment 1 is that each rotating bar is provided with an elongated bar 17 that can move on the rotating bar to change the size of the turntable, and the described elongated bar 17 and the rotating bar 8 are fixed by screws . The cross-section of the elongated bar 17 is "n"; the elongated bar 17 is outsourced on the rotating bar 8; the elongated bar 17 and the rotating bar 8 are provided with a plurality of through holes, and screws are inserted in the through holes to make the elongated bar 17 is fixed on the turning bar 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com