Epoxy resin composition for electronic packaging and preparation method thereof

An epoxy resin, electronic packaging technology, used in circuits, electrical components, electrical solid devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

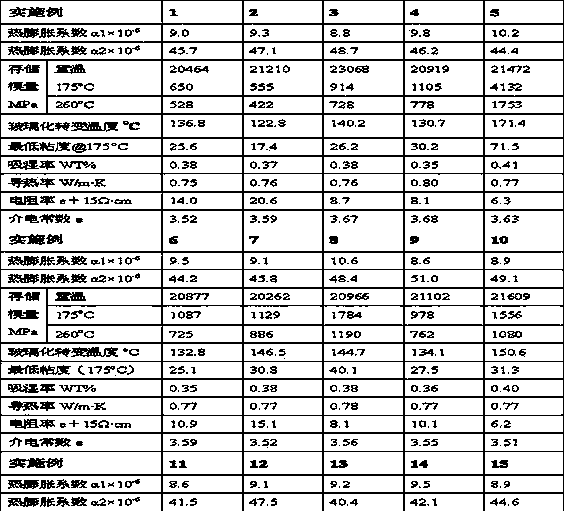

[0022] 3 parts of epoxy resin with naphthalene skeleton, 5 parts of dicyclopentadiene type epoxy resin, 2.5 parts of phenol novolac resin, 2.5 parts of phenol aralkyl novolac resin, 0.1 part of N, N'-dimethylaniline , 0.1 part of triphenylphosphine, 40 parts of spherical silica, 43 parts of fused silica, 0.8 part of coupling agent, 0.9 part of release agent, 1.3 part of stress modifier, 0.55 part of ion trapping agent, 0.25 After stirring evenly with a high-speed mixer, put it into a twin-screw extruder to heat, knead and extrude. The extruded product is calendered, cooled and crushed to obtain molding compound powder and test its performance. Product performance Listed in Table 1.

Embodiment 2

[0024] 8.4 parts of dicyclopentadiene type epoxy resin, 2.5 parts of phenol novolac resin, 2.1 parts of phenol aralkyl novolac resin, 0.1 part of N, N'-dimethylaniline, 0.1 part of triphenylphosphine, 40 parts of spherical Type silica, 43 parts of fused silica, 0.8 part of coupling agent, 0.9 part of mold release agent, 1.3 part of stress modifier, 0.55 part of ion trapping agent, 0.25 part of carbon black, after stirring evenly with a high-speed mixer, Put it into a twin-screw extruder for heating, kneading and extruding. The extruded product was calendered, cooled and pulverized to obtain molding compound powder and its properties were tested. The product properties are listed in Table 1.

Embodiment 3

[0026] 7.8 parts of epoxy resin with naphthalene skeleton, 2.5 parts of phenol novolac resin, 2.7 parts of phenol aralkyl phenolic resin, 0.1 part of N, N'-dimethylaniline, 0.1 part of triphenylphosphine, 40 parts of spherical Silicon dioxide, 43 parts of fused silica, 0.8 part of coupling agent, 0.9 part of mold release agent, 1.3 part of stress modifier, 0.55 part of ion trapping agent, 0.25 part of carbon black, after stirring evenly with a high-speed mixer, put into a twin-screw extruder for heating, mixing and extrusion, and the extruded product was calendered, cooled and pulverized to obtain molding compound powder and its properties were tested. The product properties are listed in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap