Viscosity reducing effect evaluation method and device of heavy oil viscosity reducer under stratum seepage condition

A technology of viscosity reducer and evaluation device for heavy oil, which is used in the fields of production of fluid, earth-moving drilling and production, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

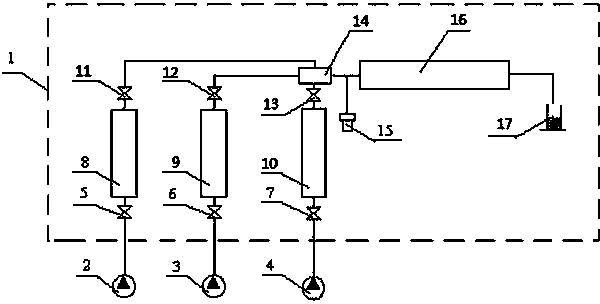

[0038] Example 1: Evaluation of the viscosity-reducing effect of oil-soluble viscosity reducer under formation seepage conditions

[0039] (a) Take 500mL of crude oil and simulated formation water with a salinity of 10000mg / L and add them respectively figure 1 Standby in the first high-pressure vessel (8) and the second high-pressure vessel (9) in the

[0040] (b) According to the concentration requirements of the viscosity reducer, add a viscosity reducer SLD with a mass concentration of 1% in the crude oil (the viscosity reducer SLD is a product that can be purchased in the existing market), mix well, and add it to the third high-pressure vessel 10 spare;

[0041] (c) According to the permeability of the target formation, select core 16, the diameter of the core is 2.54cm, the length is 20cm, and the gas permeability is 635×10 -3 μm 2 ;

[0042] (d) Adjust the temperature of the thermostat 1 to 70°C, keep the temperature constant for 8 hours, and simulate the formation...

Embodiment 2

[0052] Example 2: Evaluation of the viscosity-reducing effect of water-soluble viscosity reducer under formation seepage conditions

[0053] (a) Take 500mL of crude oil and simulated formation water with a salinity of 10000mg / L and add them respectively figure 1 Standby in the first high-pressure vessel (8) and the second high-pressure vessel (9) in the

[0054] (b) According to the concentration requirements of the viscosity reducer, add the viscosity reducer HED with a mass concentration of 1% in the simulated formation water (the viscosity reducer HED is a product that can be purchased in the existing market), mix well, and add the third high-pressure vessel 10 in standby;

[0055] (c) According to the permeability of the target formation, select core 16, the diameter of the core is 2.54cm, the length is 20cm, and the gas permeability is 686×10 -3 μm 2 ;

[0056] (d) Adjust the temperature of the thermostat 1 to 70°C, keep the temperature constant for 8 hours, and sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com