An Arrangement Structure Used for Lower Header of Boiler Wall

A technology for arranging structures and headers, applied in boiler drum/box headers, lighting and heating equipment, fluid heaters, etc. Stress and Expansion Stress, Effect of Material Use Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

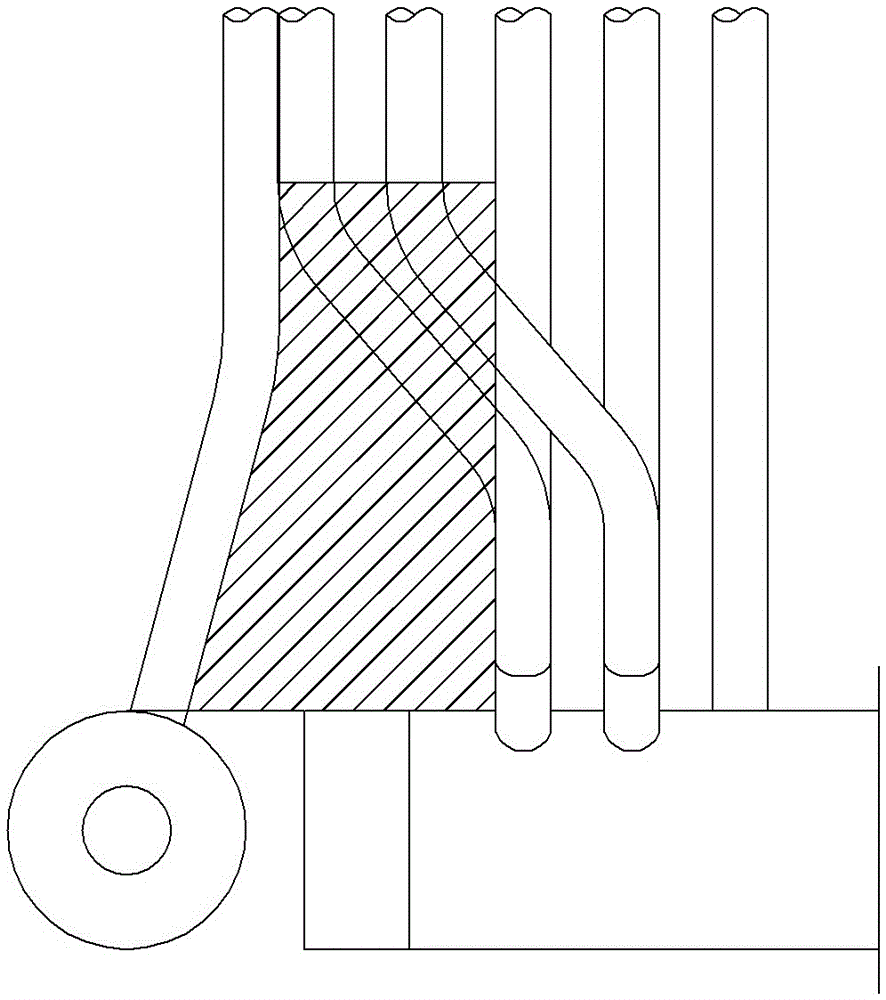

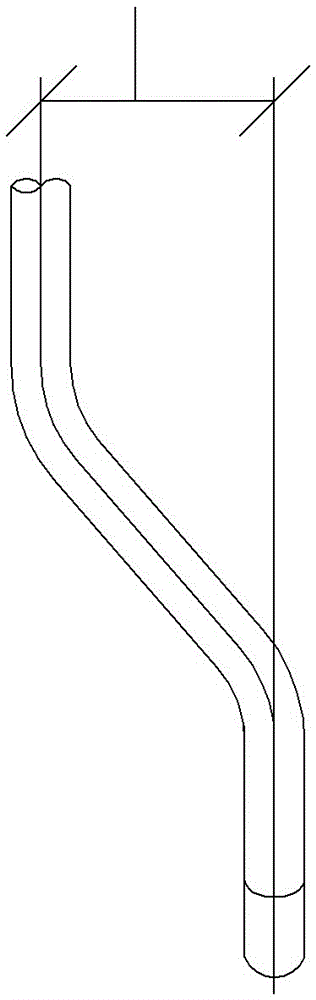

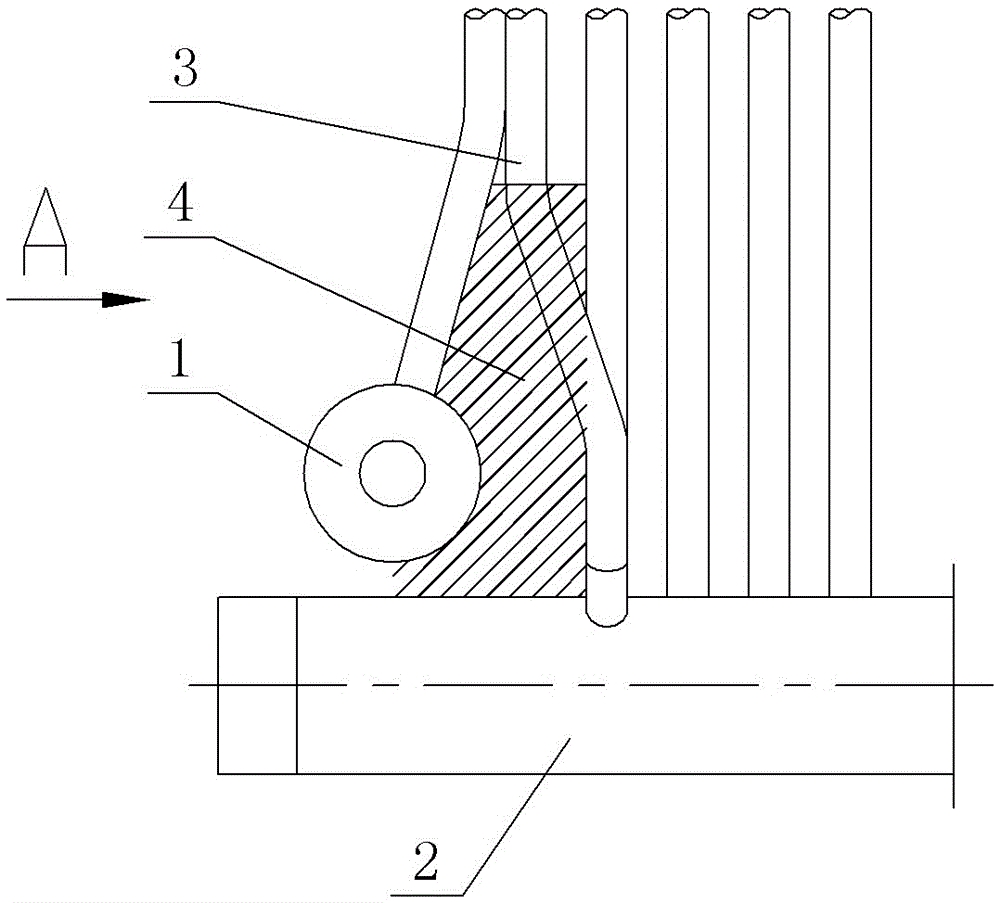

[0012] See Figure 3 ~ Figure 5 , which includes the lower header of the front wall 1, the lower header of the side wall 2, the elbow of the side wall wall 3, the sealing steel plate 4, and the sealing steel plate 4 is welded to the lower header of the front wall 1, the lower header of the side wall 2, and the side wall The isolation structure is formed after the elbow 3, the lower header 1 of the front wall is located above the level of the lower header 2 of the side wall, the side wall elbow 3 is one, and the horizontal distance of the side wall elbow 3 is reduced to half of the original. that is figure 2 Half of the horizontal distance of the middle side wall elbow, the horizontal distance of the side wall elbow 3 is 0.5L, and the sealing steel plate 4 is specifically a carbon steel sealing steel plate. Wherein, the header 1 under the front wall may also be the header under the rear wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com