Patents

Literature

38results about How to "Same expansion coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

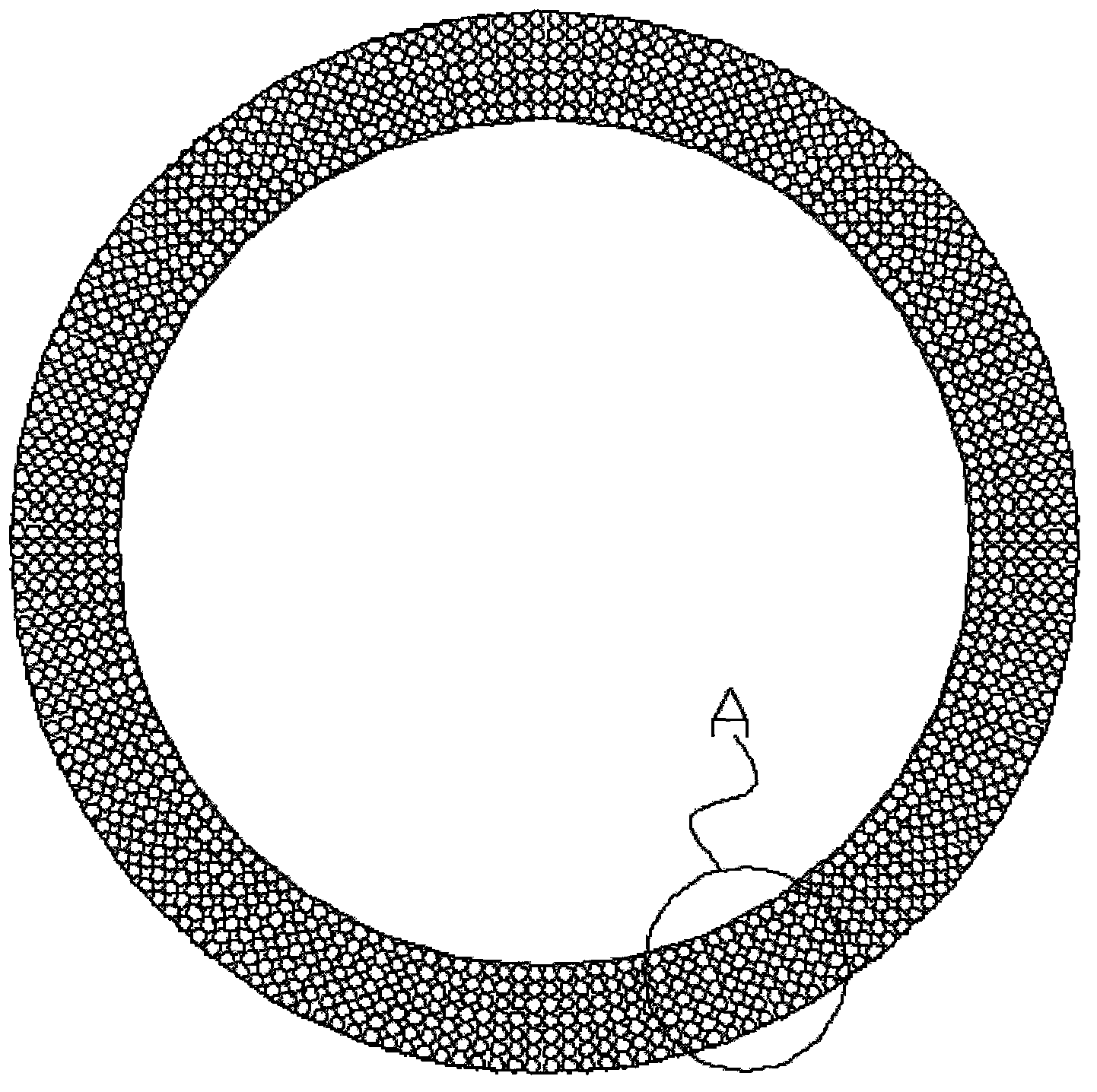

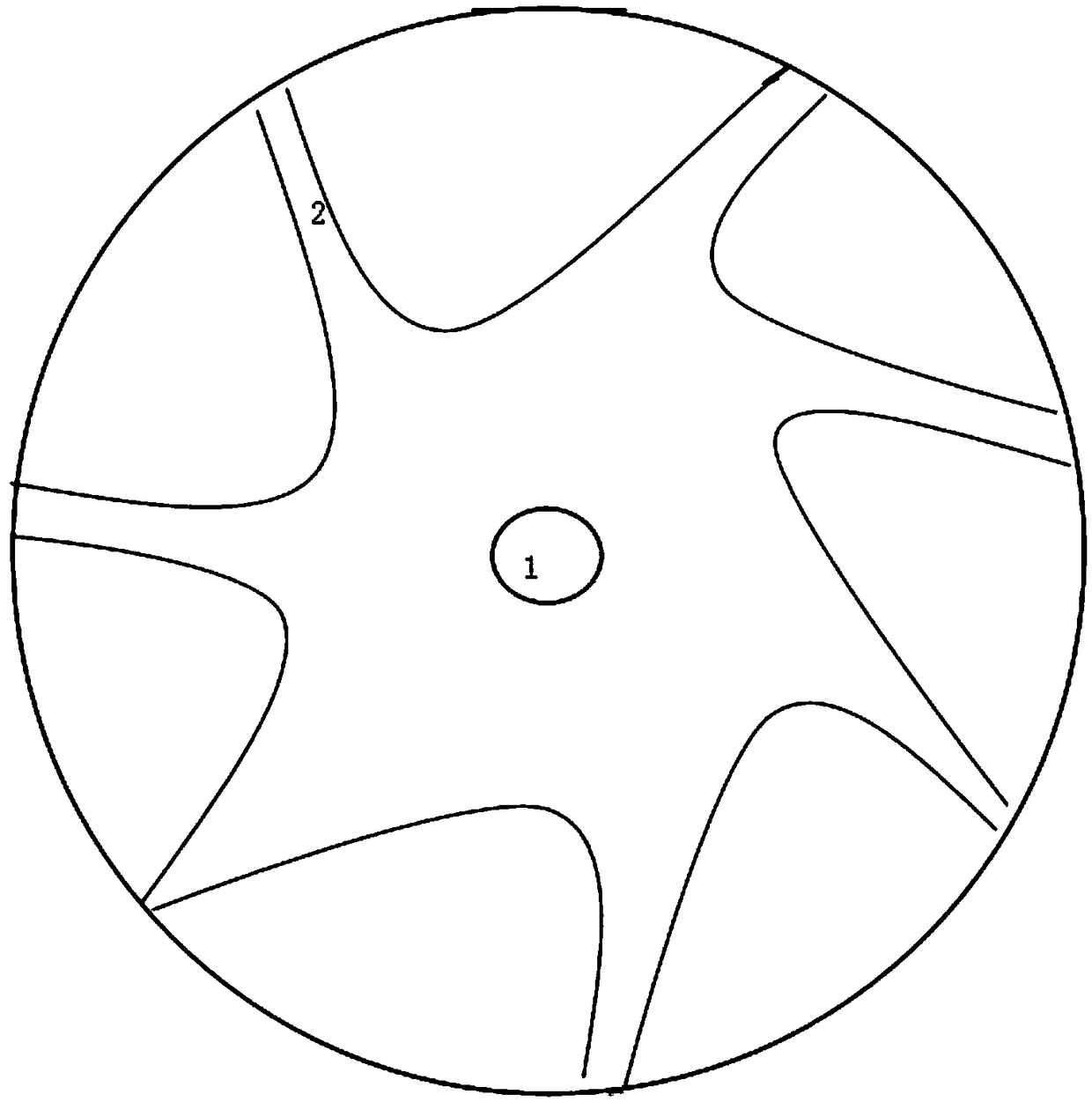

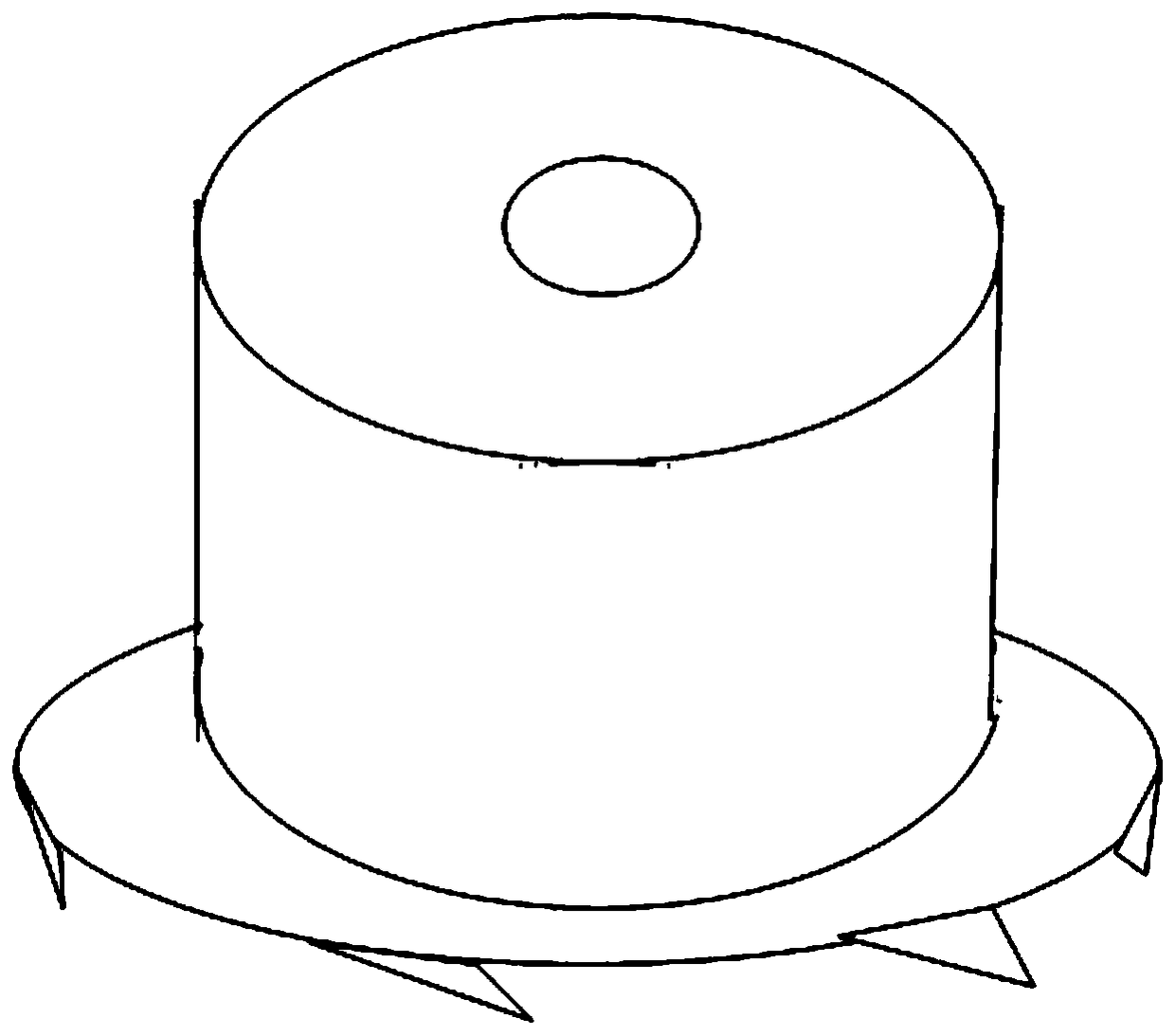

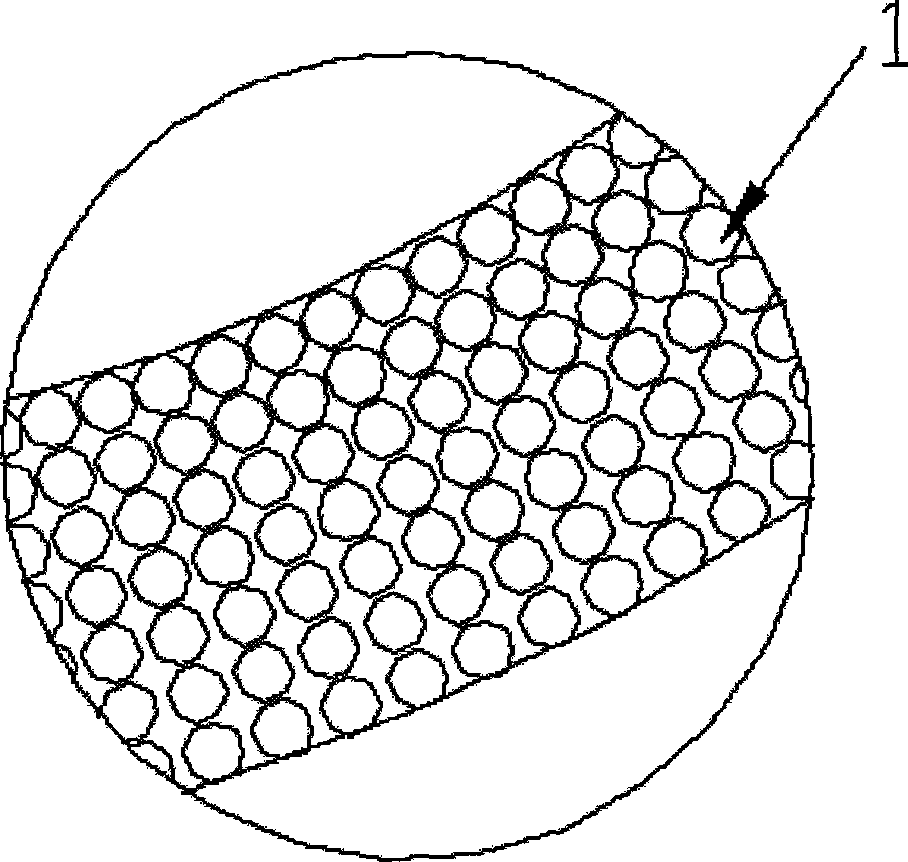

Efficient silicon carbide corundum rare earth ceramic composite grinding wheel and manufacture method thereof

The invention relates to an efficient silicon carbide corundum rare earth ceramic composite grinding wheel which comprises the following raw materials in percentage by weight: 30-75wt percent of silicon carbide abrasive, 25-70wt percent of corundum abrasive, 12-22wt percent of rare earth ceramic and 3.5-8wt percent of normal-temperature binding agent. The composite grinding wheel is manufactured by the steps of calcining, ball-milling, blending, moulding, drying, sintering, and the like. The grinding wheel of the invention has the advantages of high grinding force for grinding a difficult grinding material, sharp grains, high self sharpening, shedding in time of blunt grinding grains and no burning on workpieces. Compared with the traditional single grinding material common ceramic binding agent grinding wheel, the efficient silicon carbide corundum rare earth ceramic composite grinding wheel obviously improves the grinding efficiency; and compared with a grinding wheel adopting an expensive superhard grinding material (artificial diamond or CBN (Cubic Boron Nitride)), the efficient silicon carbide corundum rare earth ceramic composite grinding wheel obviously reduces the grinding cost and has wider adaptation and favorable economic and social benefits.

Owner:FUZHOU SHUANGYI GRINDING WHEEL +1

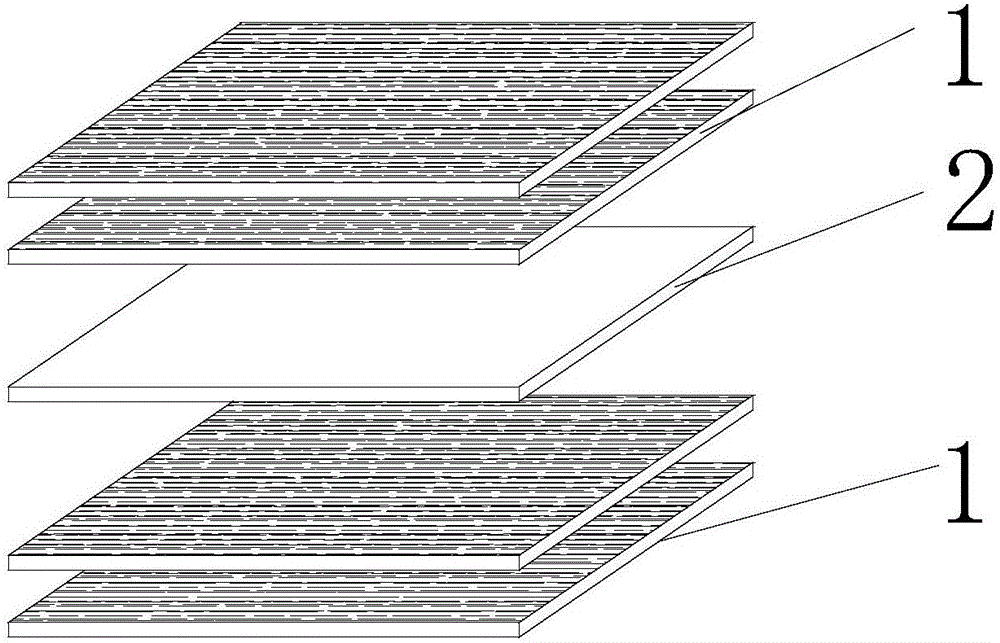

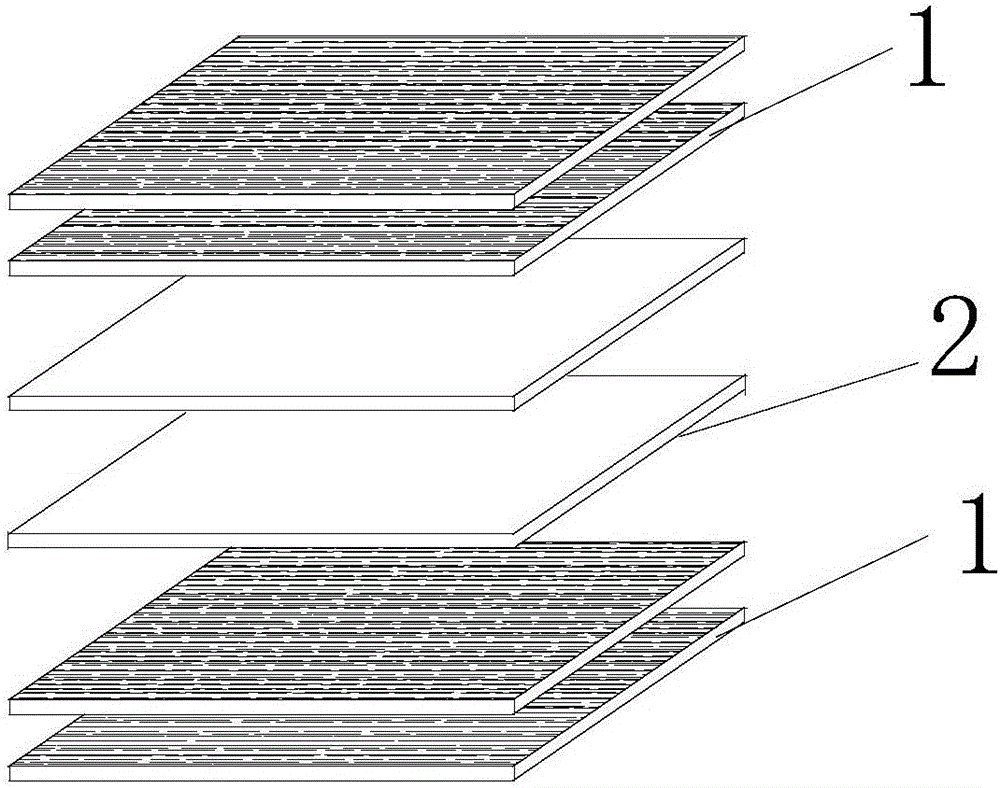

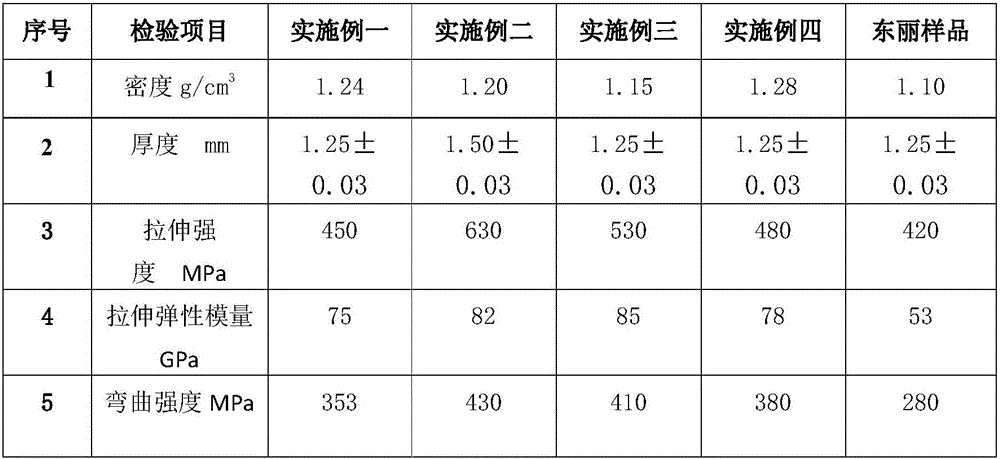

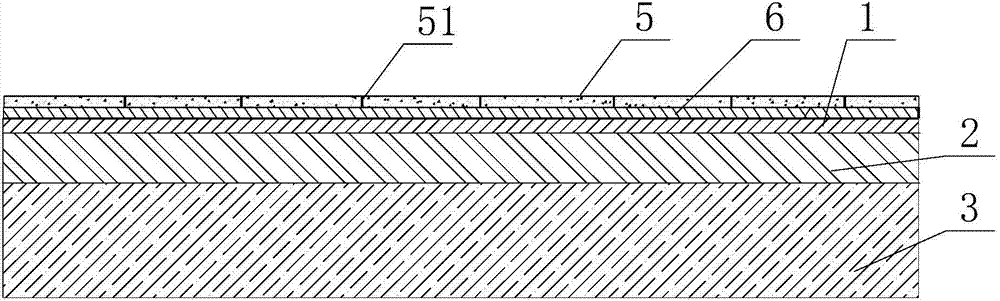

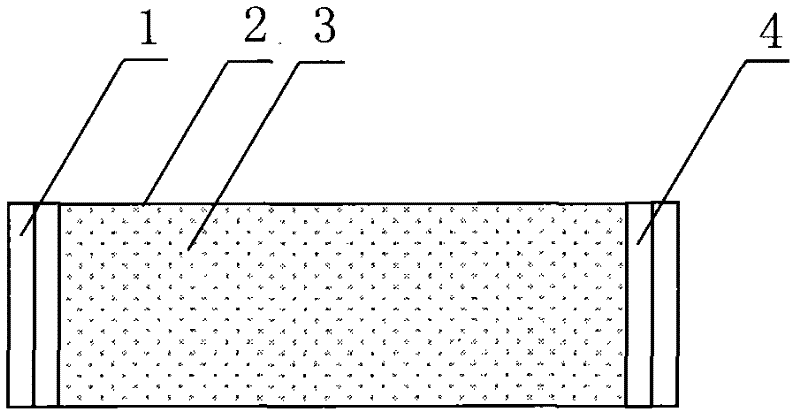

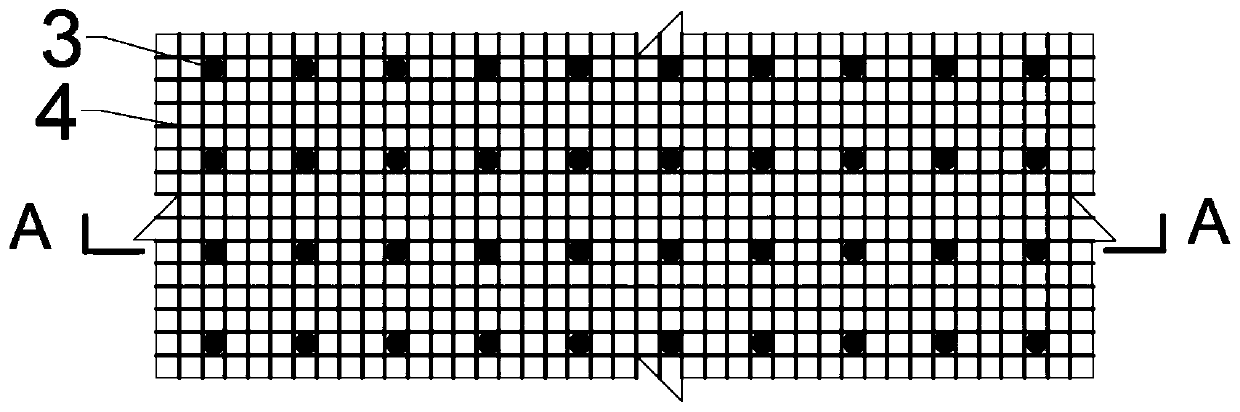

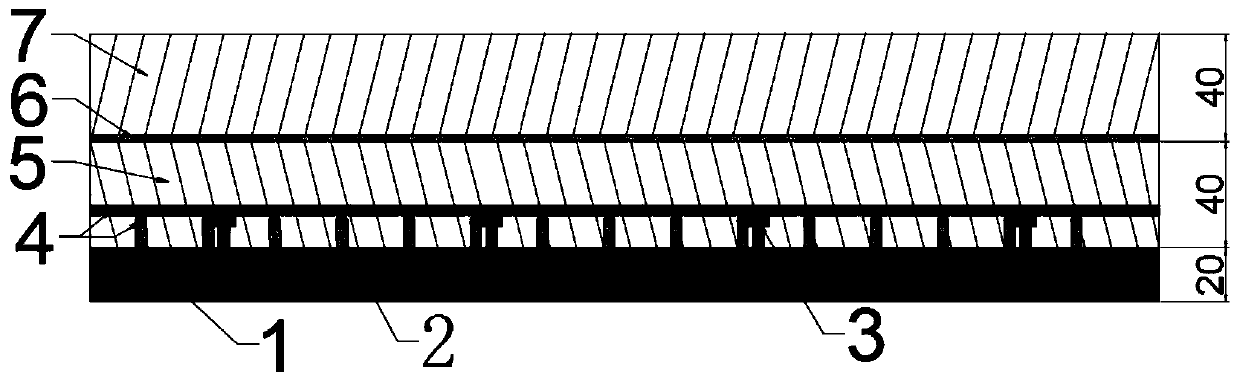

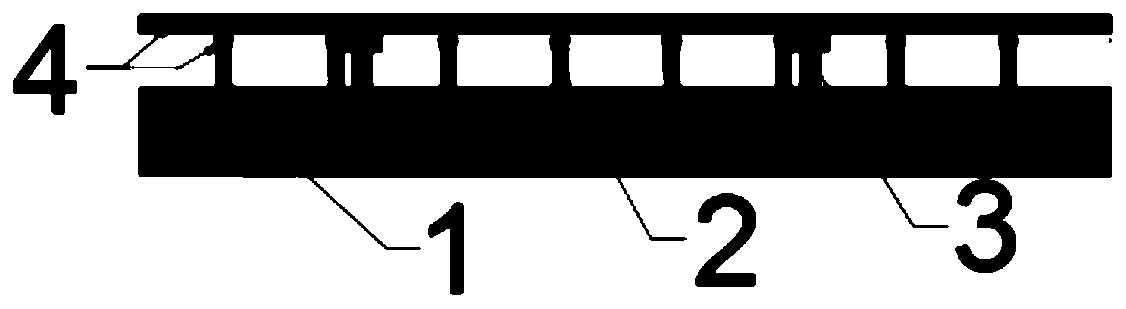

Carbon fiber sheet

InactiveCN106183135ASuitable for lightweight applicationsReduce weightSynthetic resin layered productsLaminationFiberPolymer science

The invention discloses a carbon fiber sheet, comprising no more than six layers of carbon fiber prepreg and no more than two layers of glass bead-filled epoxy sheet laminate, the glass bead-filled epoxy sheet laminate It is arranged at the middle layer position of several carbon fiber prepregs, and a layer of carbon fiber woven cloth prepreg is added between the carbon fiber prepregs and carbon fiber prepregs, carbon fiber prepregs and glass bead-filled epoxy sheet laminates . The carbon fiber sheet prepared by the invention has flame retardancy, low degree of deformation, light weight, and is easy to produce in batches, and is especially suitable for light-weight application of electronic products.

Owner:JIANGSU AOSHENG COMPOSITE MATERIALS HI TECH

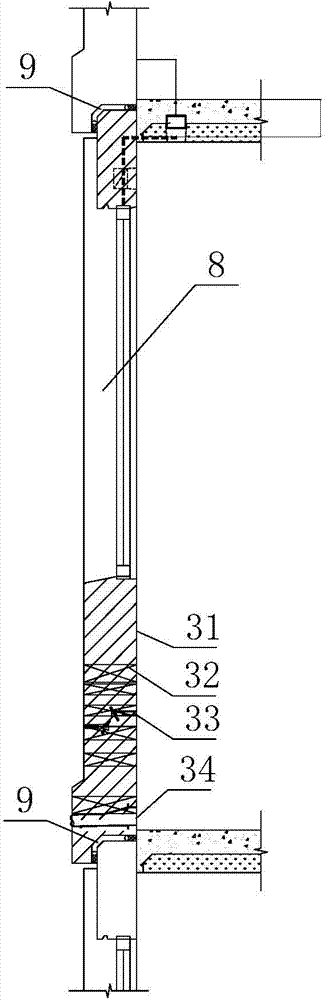

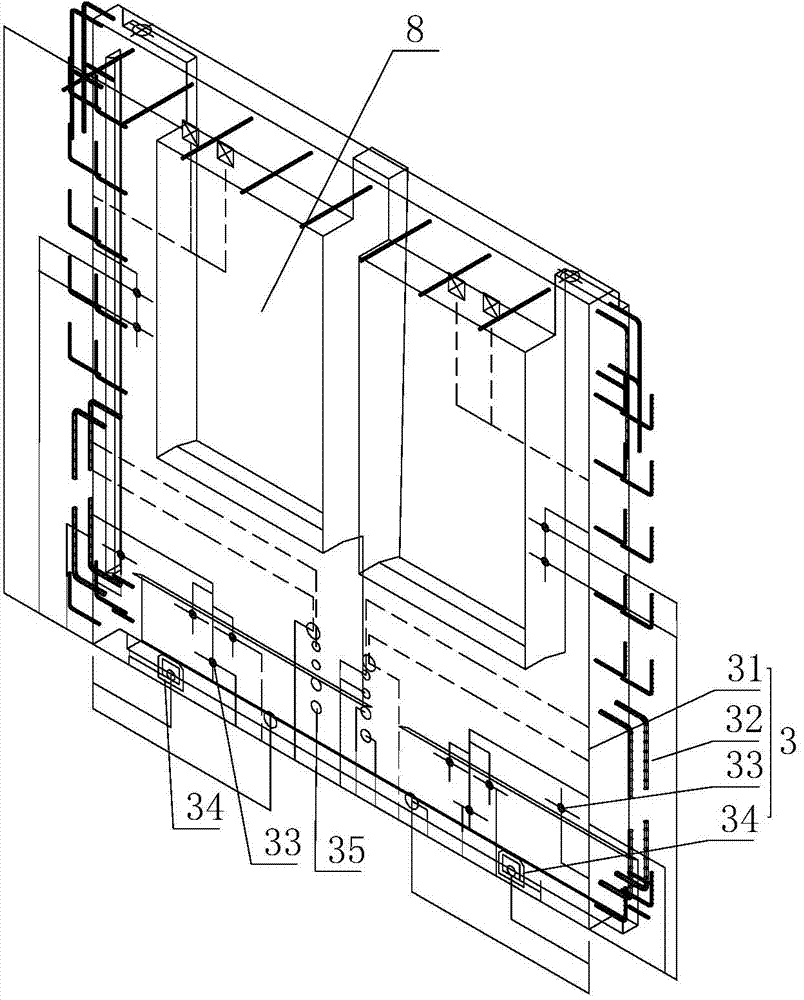

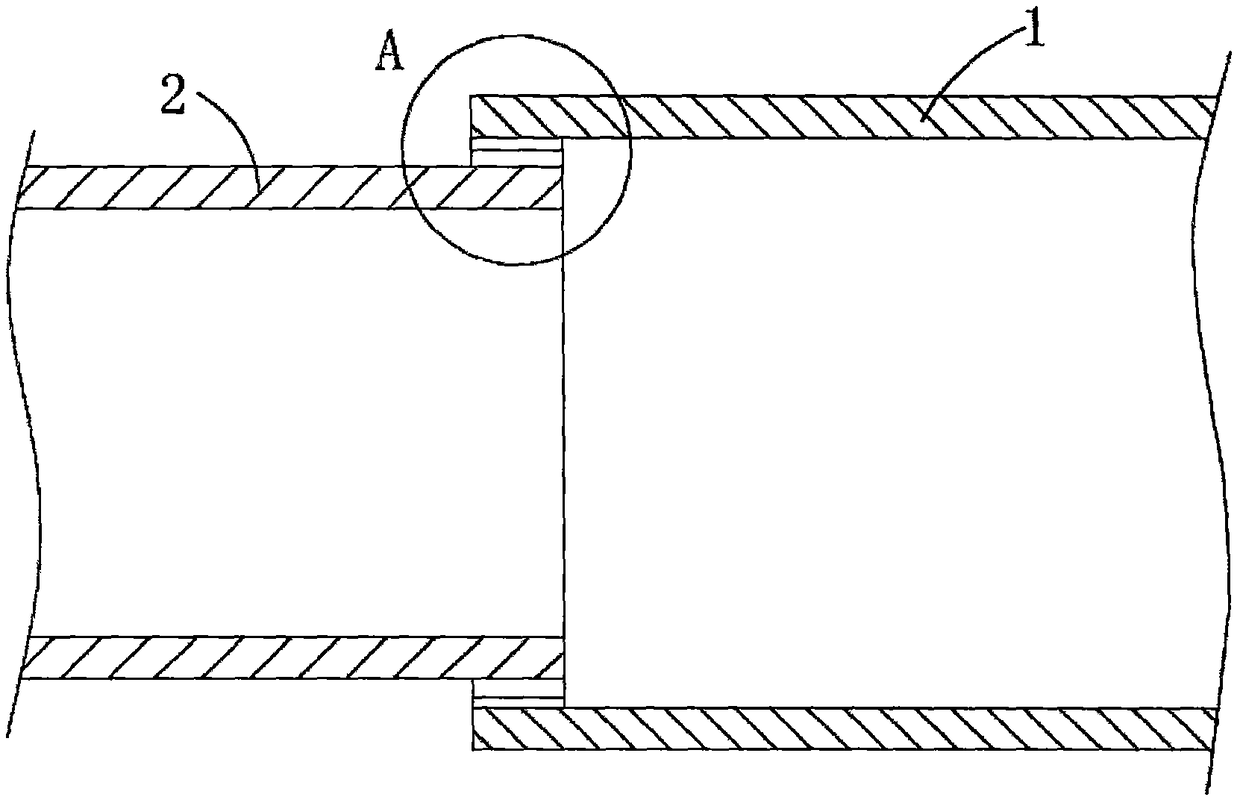

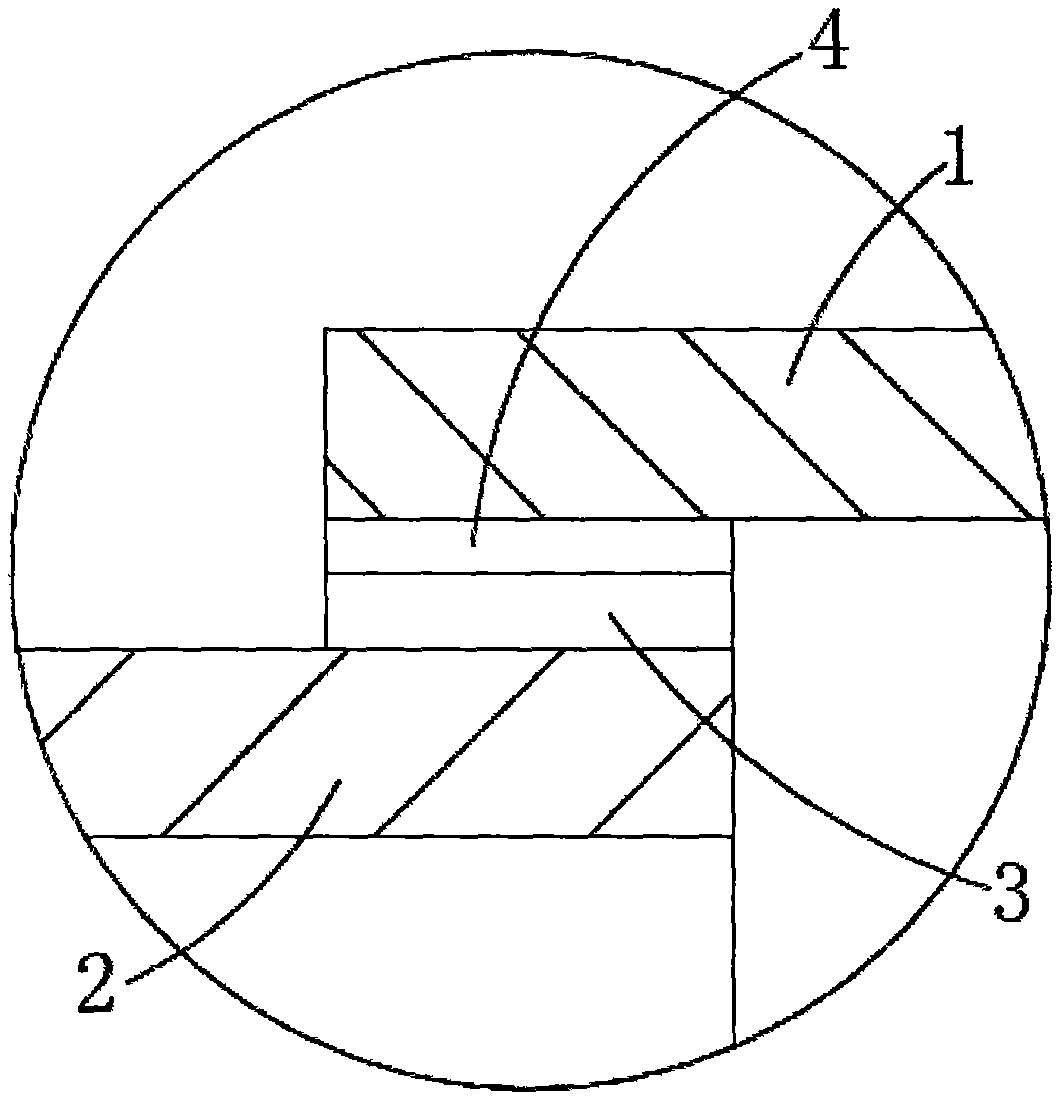

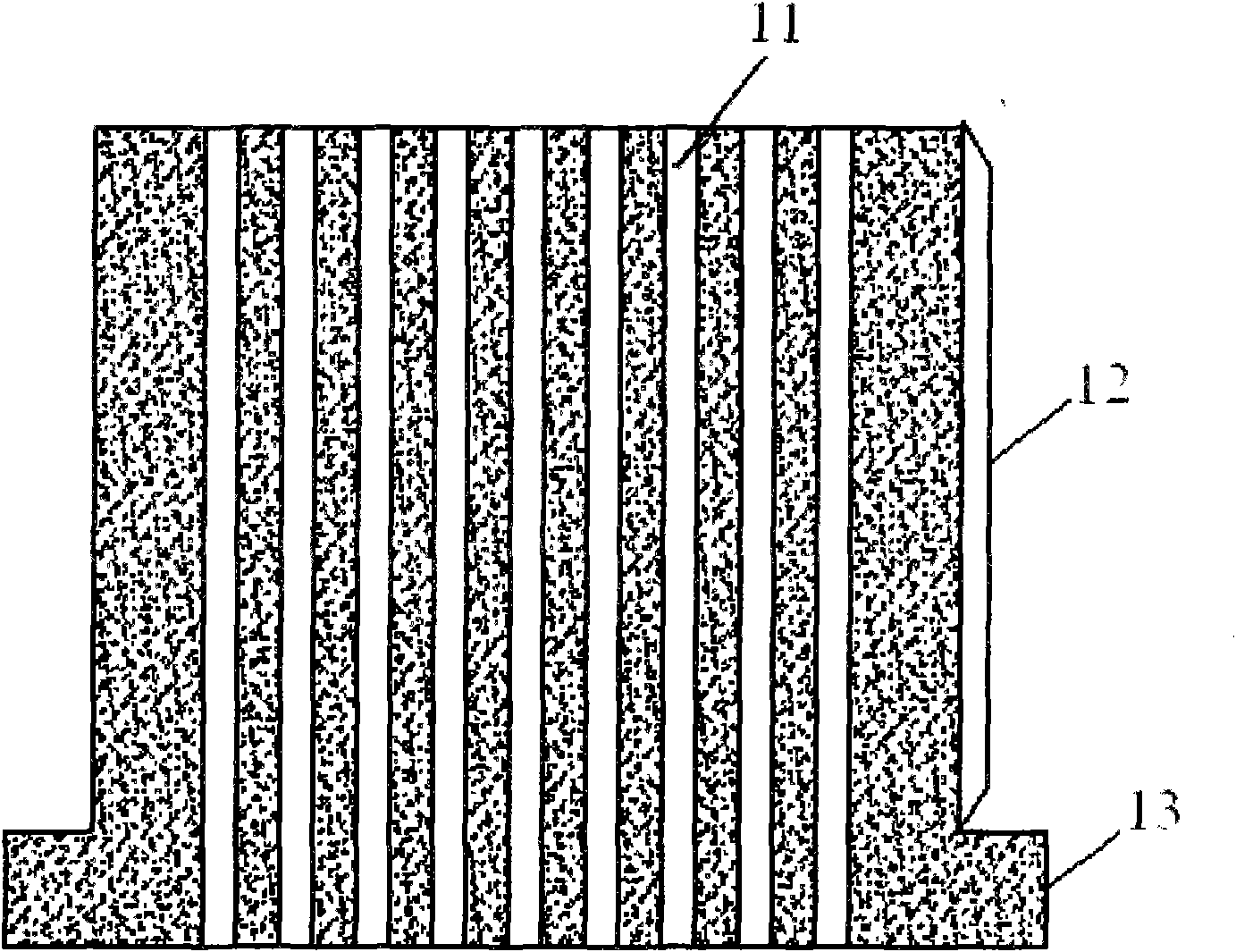

Insulating and decorating integrated composite precast concrete component and manufacturing method thereof

ActiveCN103526874ASolve the cooling problemIt has the function of energy saving and heat preservationSolid waste managementBuilding componentsWeather resistanceBrick

The invention discloses an insulating and decorating integrated composite precast concrete component and a manufacturing method thereof. The precast concrete component comprises decorative wall face bricks and a precast portion, wherein the decorative wall face brick and the precast portion are integrally solidified through a bonding mortar layer, and the precast portion is of a non-layered composite structure which is sequentially formed by solidifying a crack-resistant face layer, an insulating layer and a concrete layer. The concrete layer comprises filling concrete, a framework and an embedded part, wherein the framework extends into the insulating layer. The precast component is good in insulation, good in consistency, free of layering and easy to install. The manufacturing method comprises the steps of assembling and processing a mould, previously processing and laying the wall face bricks, sequentially pouring the crack-resistant face layer, the insulating layer and the concrete layer, and finally processing the surface of the whole component. The manufacturing method is simple in process. The manufactured precast component is high in quality, high in weather resistance and not prone to layering.

Owner:山东海龙建筑科技有限公司

Automobile air compressor aluminum cylinder block

InactiveCN101334021AExtended service lifeSolution to short lifePositive displacement pump componentsPositive-displacement liquid enginesCylinder blockAir compressor

The invention relates to a component of a vehicle air compressor, in particular to an aluminum cylinder body of a vehicle air compressor. The aluminum cylinder body is characterized in that an inner hole surface of the aluminum cylinder is provided with a compound millimicron material coating with the ingredient being Ni and SiC of 40 to 60 nm granularity. Therefore, the aluminum cylinder body has the advantages of gas blowby resistance and oil pumping resistance of the compressor, abrasion resistance, corrosion resistance, good high-temperature oxidation resistance and long service life.

Owner:LONGKOU DACHUAN PISTON

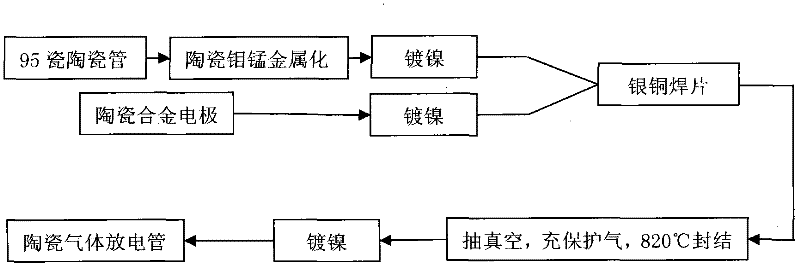

Ceramal material, and application thereof in ceramic-to-metal sealed electrode

The invention provides a ceramal material, and an application of the material in ceramic-to-metal sealed electrodes. The ceramal material is produced from the raw materials of, by weight: 50 to 60% of ceramic powder, 35 to 45% of molybdenum powder or tungsten powder, and 5 to 10% of manganese powder. The ceramic powder and the ceramic product have a same formula. With the technical scheme of the present invention, a problem of coupling between ceramic-to-metal sealed electrodes and expansion coefficient of ceramics is solved, a problem in producing electrodes with complicated shapes is solved, and the production cost is reduced.

Owner:刘颂辉

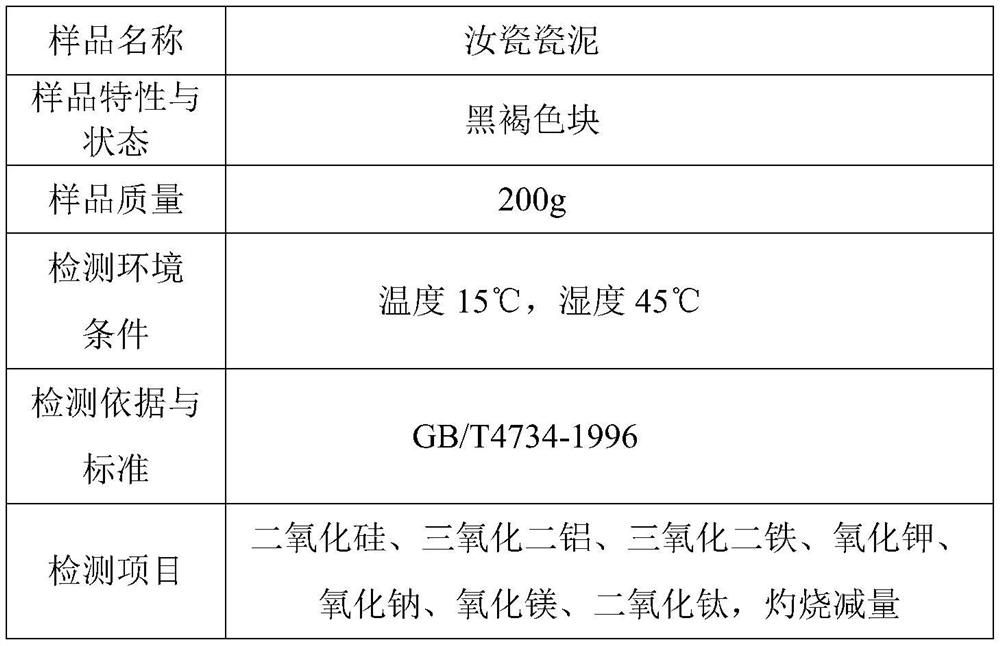

No-cracking Ru porcelain tableware and no-cracking manufacture method of Ru porcelain tableware

The invention discloses no-cracking Ru porcelain tableware and a no-cracking manufacture method of the Ru porcelain tableware. The porcelain comprises: a blank body and glaze materials which are usedfor manufacturing tableware; the blank body raw materials comprise Tanggou soil, Banpo soil and Heimao soil; the glaze raw materials comprise mica, horseshoe stones, agate stones, plant ash and sheepbone meal; the blank body raw materials and the glaze raw materials are crushed, water is added, wet grinding is carried out, and water is discharged after precipitation; slurry of the blank body rawmaterial is injected into a mold, and firing is carried out for forming a biscuit; glazing is carried out on the outer surface of the blank body raw material biscuit; and the blank body is placed intoa kiln, the furnace temperature of the kiln is raised to 1050 DEG C, heating is carried out at a speed of 1 DEG C every two minutes, when temperature is increased to 1280-1300 DEG C, heat preservation and firing are carried out on the blank body under a condition of 1280-1300 DEG C, and then firing is finished. Through the mode, according to the porcelain provided by the invention, the formula ofthe porcelain and the manufacturing method are improved, the expansion coefficients of the glaze materials and the biscuit are consistent, so that the phenomenon that existing Ru porcelain is crackedand the glaze surface of the surface is cracked is changed, no cracks and no fracture exist on the porcelain, and the manufactured porcelain can be made into high-grade tableware.

Owner:汝州市宣和坊汝瓷有限公司

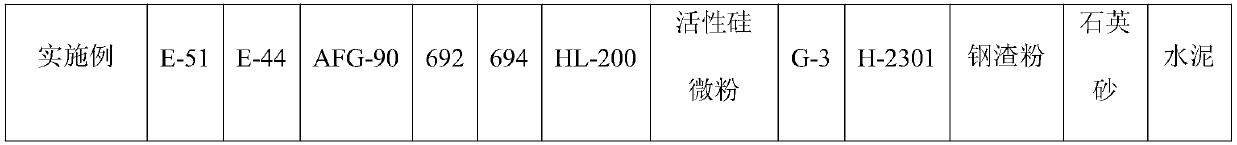

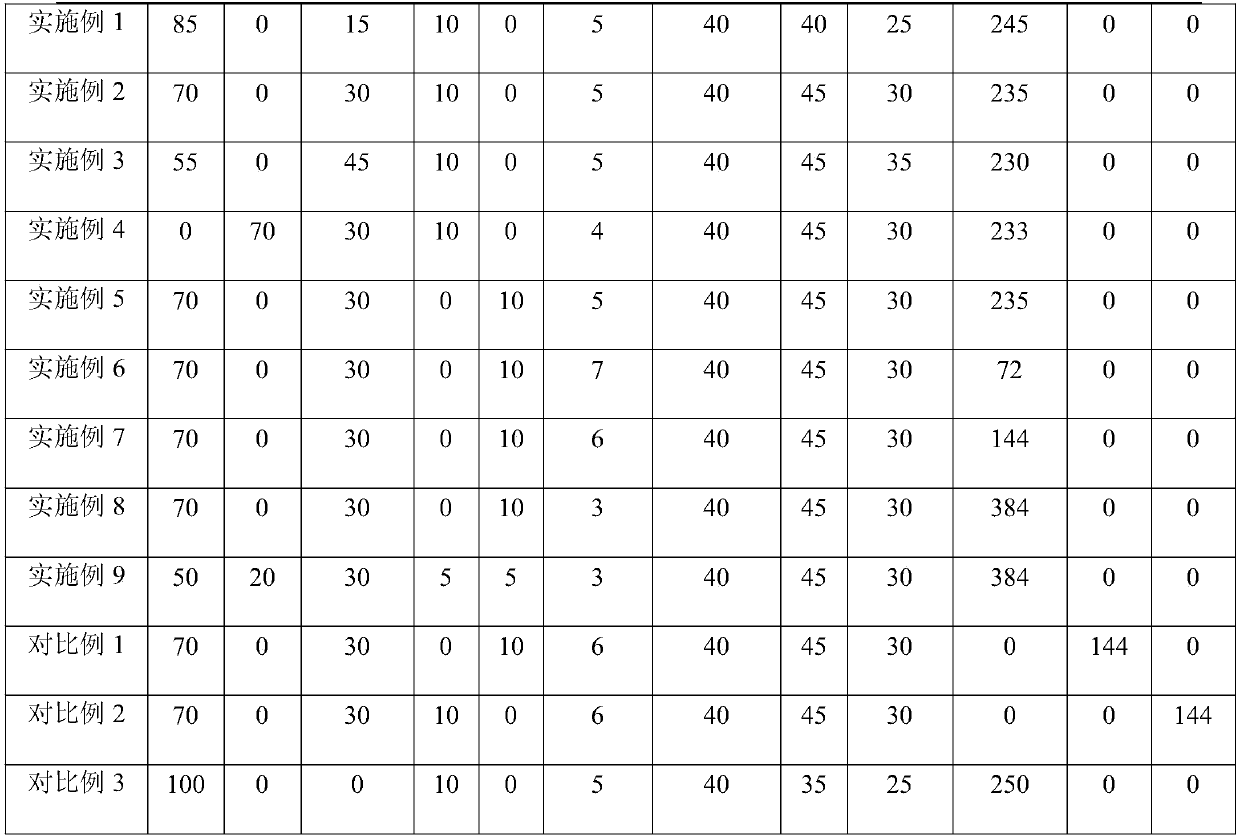

High-density underwater epoxy repair adhesive and preparation method and application thereof

InactiveCN109536102AHigh reactivityQuick fixNon-macromolecular adhesive additivesEpoxy resin adhesivesHigh densitySlag

The invention relates to a high-density underwater epoxy repair adhesive and a preparation method and application thereof. The high-density underwater epoxy repair adhesive comprises a component A anda component B, wherein the component A comprises, in parts by mass, 50-100 parts of bisphenol A-type epoxy resin, 0-50 parts of low-viscosity amino-phenolic tri-functional group epoxy resin, 0-15 parts of a reactive diluent, 0-10 parts of a thixotropic agent and 20-60 parts of active silicon micropowder, and the component B includes, in parts by mass, 30-60 parts of Mannich modified phenolic amine, 20-50 parts of modified alicyclic amine and 0-600 parts of steel slag powder. The high-density underwater epoxy repair adhesive is applied to repairing of underwater buildings, and has the advantages of environmental protection, fast solidification, high density and high bonding strength.

Owner:CHINA BUILDING MATERIAL TEST & CERTIFICATION GRP XIAMEN HONGYE

Cold-rolling production method for controlled expansion alloy strip

ActiveCN106623419AImprove uniformityWide range of fixed expansion coefficientsMetal rolling arrangementsAlloyWeld seam

The invention relates to a machining process for an alloy strip, in particular to a cold-rolling production method for a controlled expansion alloy strip. The cold-rolling production method is characterized by comprising the steps that a refined hot-rolled coiled plate is selected; the refined hot-rolled coiled plate is subjected to primary rolling, washing and annealing; then the refined hot-rolled coiled plate is subjected to secondary rolling, washing and annealing; and then the refined hot-rolled coiled plate is subjected to pull straightening, high-temperature aging treatment and reverse pull straightening to obtain the controlled expansion alloy strip. By adoption of the method for producing the controlled expansion alloy strip, no welding is needed, no welding seam exists in the strip, and the controlled expansion alloy strip is large in coiling diameter and good in uniformity and is 9.3*10<-6> DEG C / m in linear expansion coefficient at 20-400 DEG C.

Owner:无锡华生精密材料股份有限公司

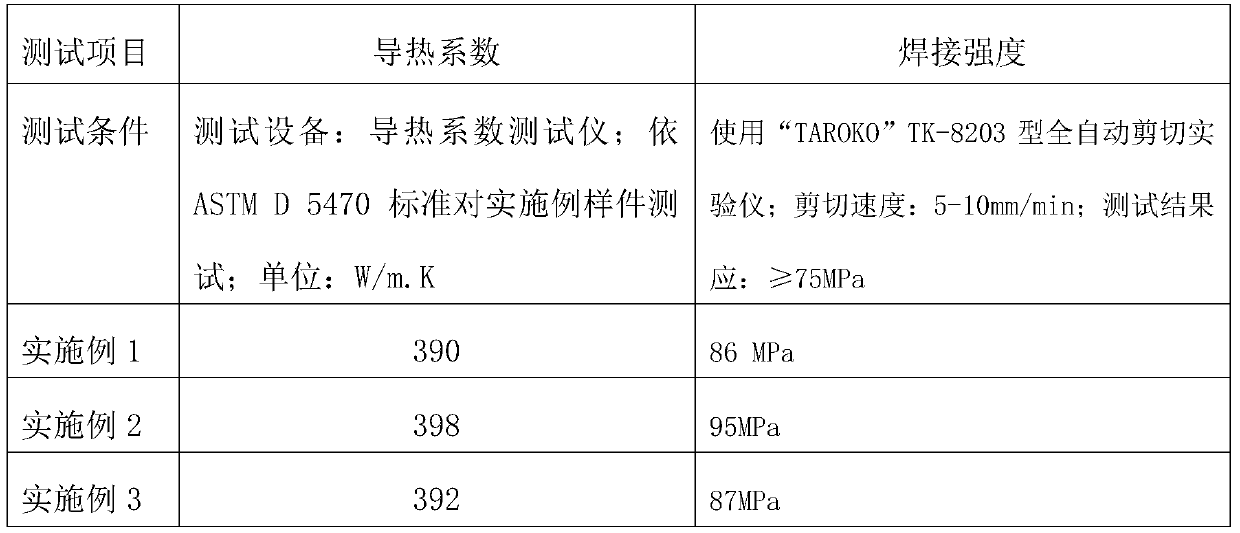

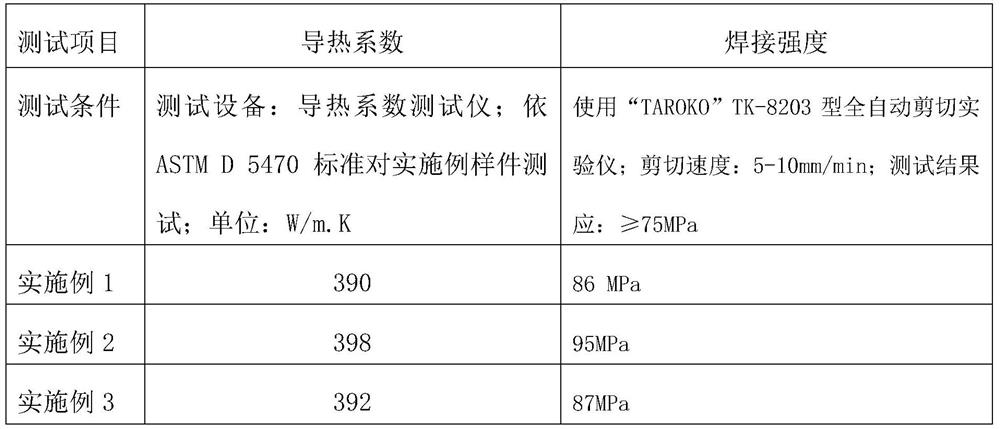

Copper-nickel-silver brazing slurry and preparation method thereof

ActiveCN111482734AHigh strengthSolve the problem of brazing strengthWelding/cutting media/materialsSoldering mediaSlurryCopper

The invention discloses a copper-nickel-silver brazing slurry and a preparation method thereof. According to the copper-nickel-silver brazing slurry and the preparation method thereof, copper-nickel-silver with the more stable alloy performance is adopted as a main base material, the copper-nickel-silver brazing slurry is prepared through cooperation of brazing flux, and the copper-nickel-silver brazing slurry can be used for brazing of a large number of heat dissipation materials with copper, silver, nickel and other base materials as main materials and external parts at present. According tothe obtained copper-nickel-silver brazing slurry, the strength of a brazed joint after welding is high, the heat conductivity coefficient and the expansion coefficient are kept consistent with thoseof a heat dissipation base material, and poor product performance caused by expansion coefficient difference can be effectively avoided.

Owner:浙江力强科技有限公司

Constructing method for integrated precast concrete component

InactiveCN104290188AHigh bonding strengthGood compatibilityCeramic shaping apparatusBrickInsulation layer

The invention discloses a constructing method for an integrated precast concrete component. The constructing method comprising the following steps of splicing and processing a die; pasting tapestry bricks and conducting water finish on the base faces of the tapestry bricks; pasting mortar and casting mortar mixed materials to the tapestry bricks to obtain a layer of adhesion layer; installing frameworks of steel reinforcement and embedded parts on the die according to the construction requirement; preparing concrete mixed materials well according to the slump of concrete, and pouring the concrete mixed materials into the die, vibrating the die to make the concrete mixed materials compact; checking the forming situation after the die is removed from the component, repairing flaws on the surface of the component in time, and carrying out surface cleaning and polishing treatment. The constructing method for the integrated precast concrete component is simple in construction process, and the adhesion strength of the tapestry bricks and a structural layer is much higher than that of later-stage construction. Due to the fact that materials of an insulation layer are similar to the concrete materials, the material compatibility is better, combination is tighter, safety is greatly increased, finish coat decoration is not needed on the construction site, and potential safety hazards like work high above the ground are avoided.

Owner:安徽海龙建筑工业有限公司

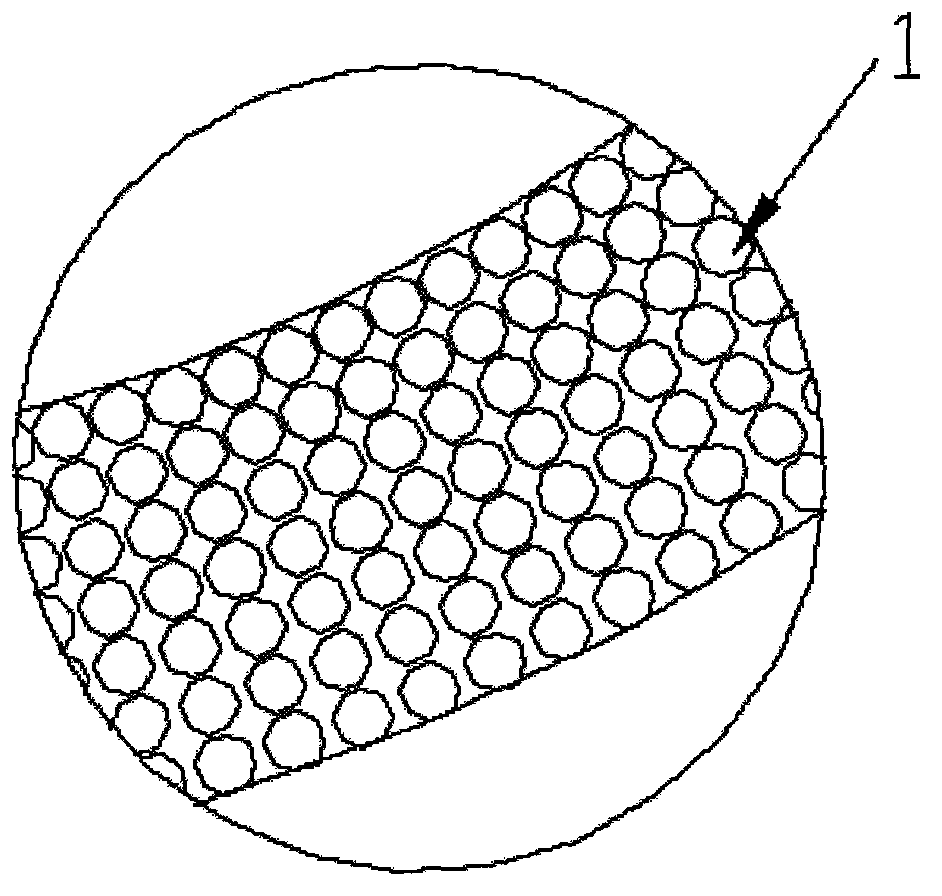

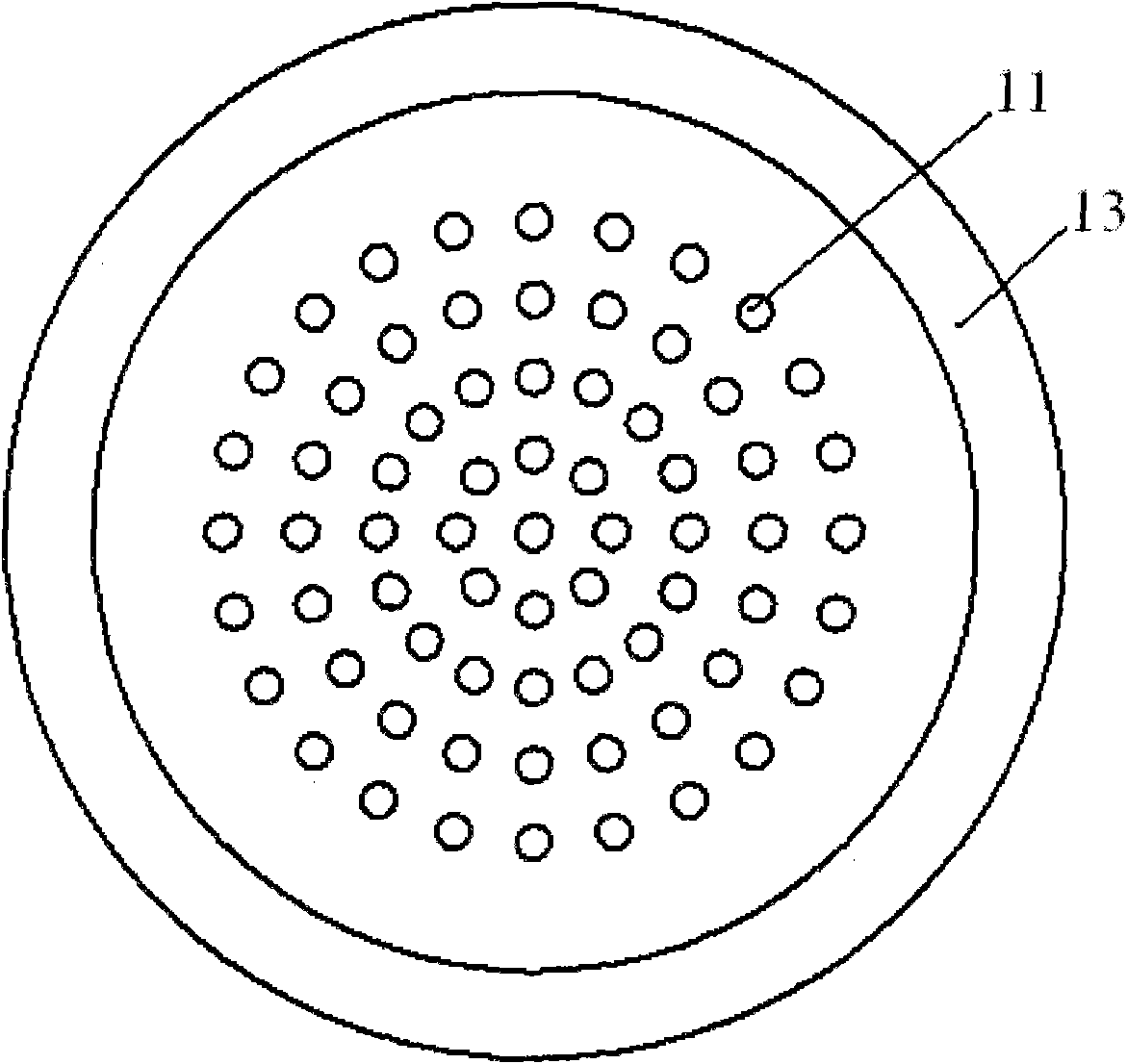

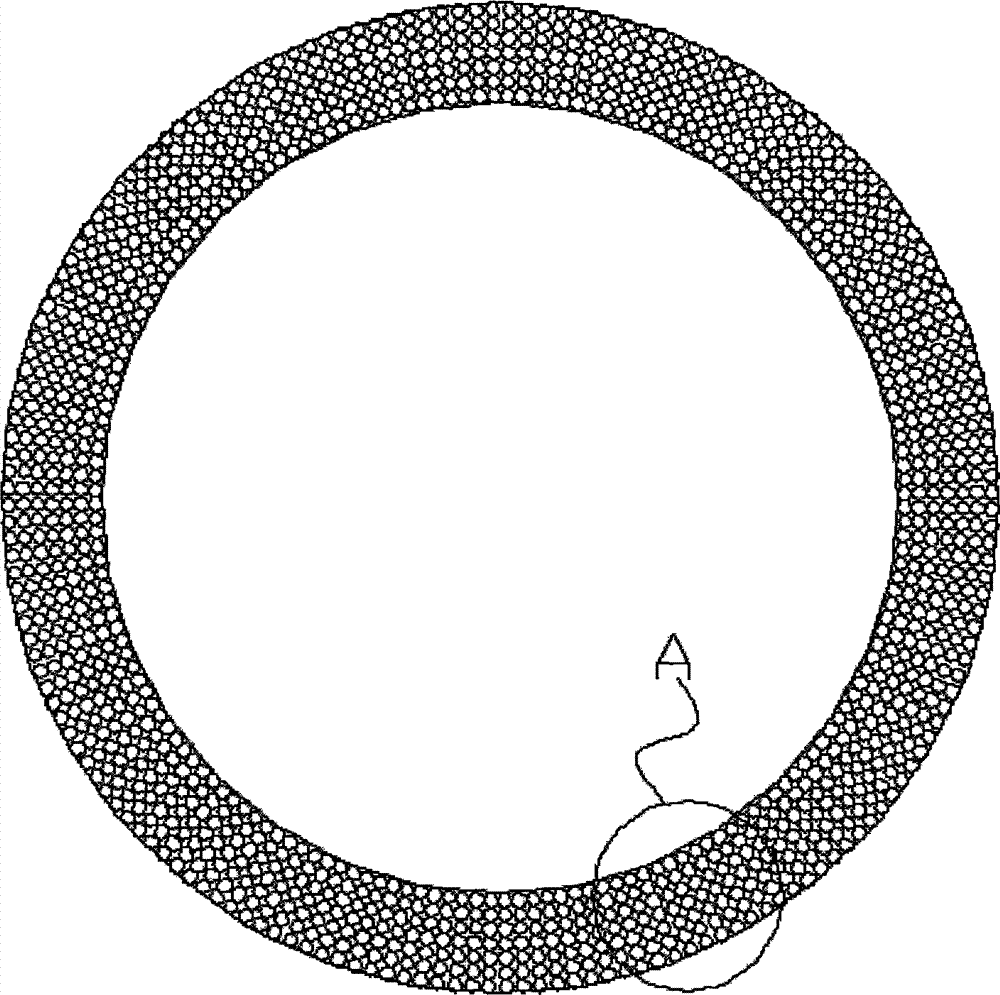

Homogenic inorganic membrane tube and preparation method thereof

ActiveCN103170252AUniform diameterReduce weightSemi-permeable membranesCentrifugal forceRaw material

The invention relates to a preparation method of a homogenic inorganic membrane tube, belongs to the technical field of inorganic membranes and relates to a preparation method of inorganic membrane tubes and membrane tubes thereof. The method comprises the following steps of: 1) screening homogenic base materials with uniform or same particles in size; 2) uniformly mixing base materials with water and water glass to form an inorganic membrane tube raw material; 3) filling the inorganic membrane tube raw material to a centrifugal casting inorganic membrane tube machine and manufacturing a membrane forming tube by centrifugal force; and 4) demoulding, sintering and cooling to form. The homogenic inorganic membrane tube provided by the invention is simple to manufacture and free from drying and demoulding, so that the production efficiency is greatly improved and the production cost is lowered. The inorganic membrane tube products prepared by the invention are consistent in filter layers, and the filter precision of the tube products washed and damaged is still maintained consistent.

Owner:GUANGDONG INST OF ENG ENERGY SAVING & EMISSION REDUCTION TECH

A dual-band multi-polarization common-aperture waveguide slot antenna

ActiveCN104577347BAchieve sharingImprove antenna efficiencySimultaneous aerial operationsSlot antennasCross polarizationWaveguide

The invention relates to a dual-band multi-polarization common-aperture waveguide slot antenna. Including L-band vertically polarized antennas, C-band vertically polarized antennas and C-band horizontally polarized antennas with equal lengths; and all of them are waveguide slot antennas; C-band vertically polarized antennas and C-band horizontally polarized antennas form a C-band dipole The polarized antenna array is located at the upper part, and the L-band vertically polarized antenna is located at the lower part; the L-band vertically polarized antenna, the C-band vertically polarized antenna and the C-band horizontally polarized antenna are all fed through the center of the antenna waveguide through a coaxial connector. Electrically, the coaxial connector and the waveguide form a 3dB power divider; realize the excitation of the L-band vertically polarized antenna, the C-band vertically polarized antenna and the C-band horizontally polarized antenna. The invention realizes sharing of multiple waveguide slot antennas on the same physical aperture area. Compared with the dual-band multi-polarization microstrip common-aperture antenna, the antenna has high efficiency, high polarization isolation, low cross polarization, and low power capacity. Great advantages.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

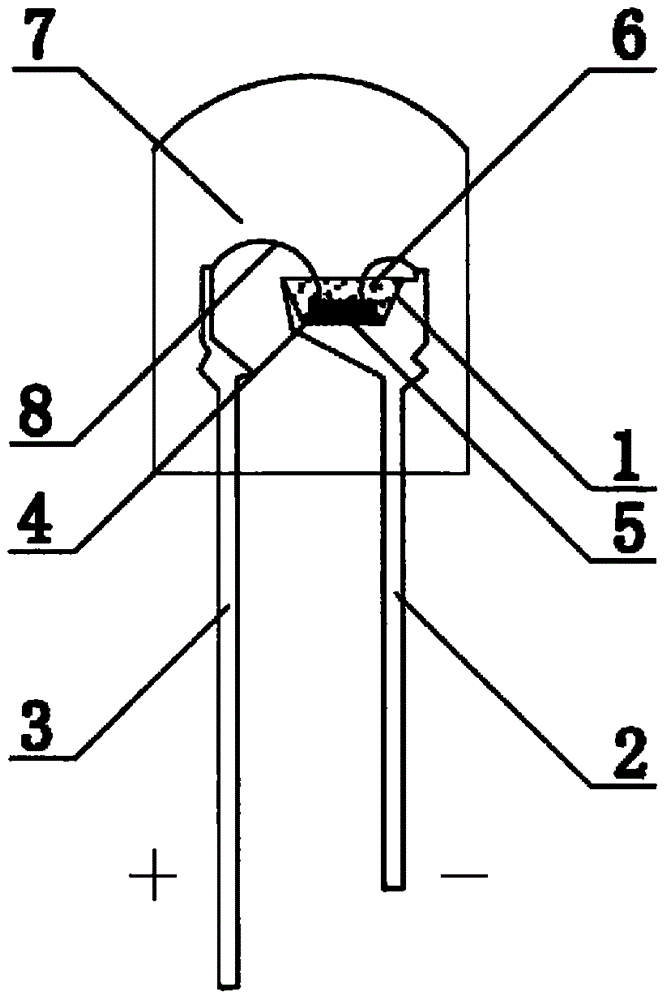

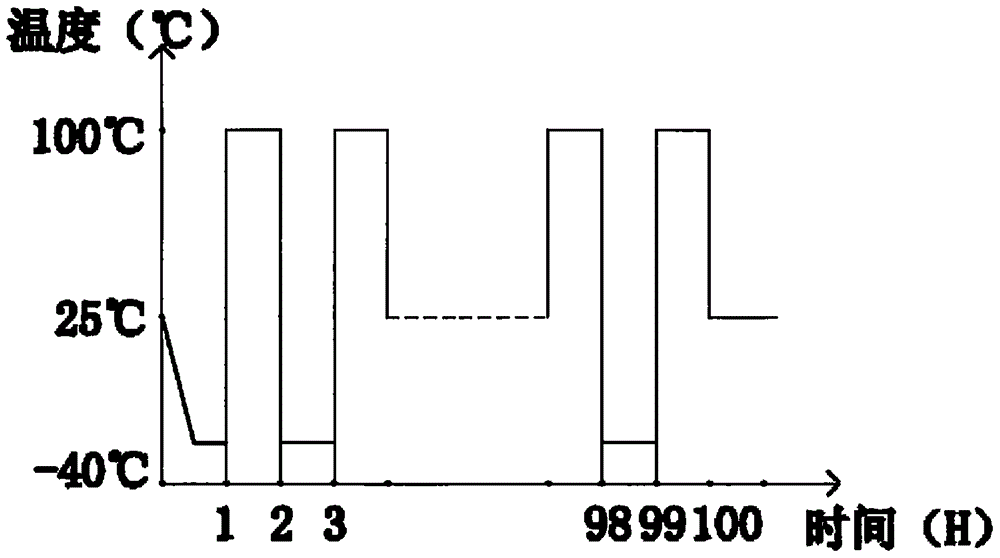

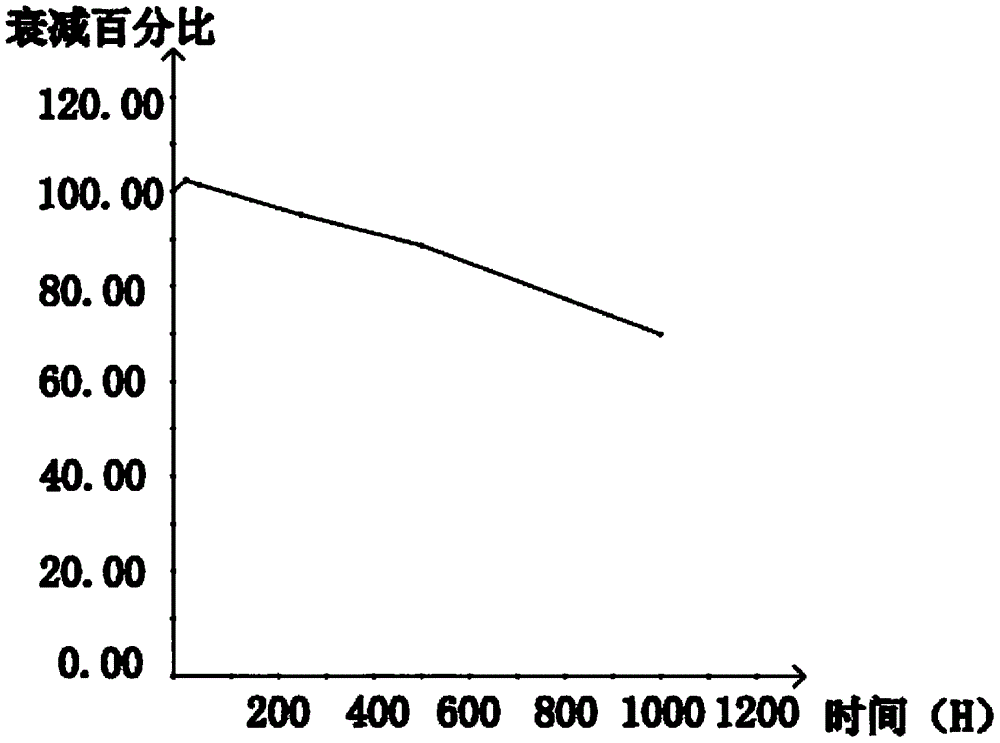

Low-light-decay ultraviolet LED and manufacturing method thereof

InactiveCN105870307ASame expansion coefficientSolve the problems that have plagued the industry for more than ten yearsSolid-state devicesSemiconductor devicesEpoxyUltraviolet

The invention discloses a low-light-decay ultraviolet LED and a manufacturing method thereof. The low-light-decay ultraviolet LED comprises a bowl cup. An ultraviolet chip is fixed to the inner bottom of the bowl cup through crystal fixing glue. The ultraviolet chip is connected with a positive electrode guide post and a negative electrode guide post through a pair of gold bonding wires, the bowl cup is filled with inner glue, and outer glue is packaged outside the bowl cup. The inner glue is organosilicone modified epoxy resin, wherein the glue AB is prepared from, by weight, 10 parts of glue A and 6 parts of glue B. The outer glue is epoxy resin, wherein the glue AB is prepared from, by weight, 100 parts of glue A and 100 parts of glue B. The composition of the outer glue and the composition of the inner glue are roughly consistent, and when the inner glue and the outer glue are combined, the problems of bubbles and layering are completely solved. The expansion coefficient of the inner glue and the expansion coefficient of the outer glue are consistent, internal stress is basically eliminated, the LED can still normally work under 100 times of cold and hot impacts, and due to the fact that components of the inner glue are subjected to silicone modification, the ultraviolet transmission and the light decay performance of the LED are greatly improved.

Owner:浙江单色电子科技有限公司

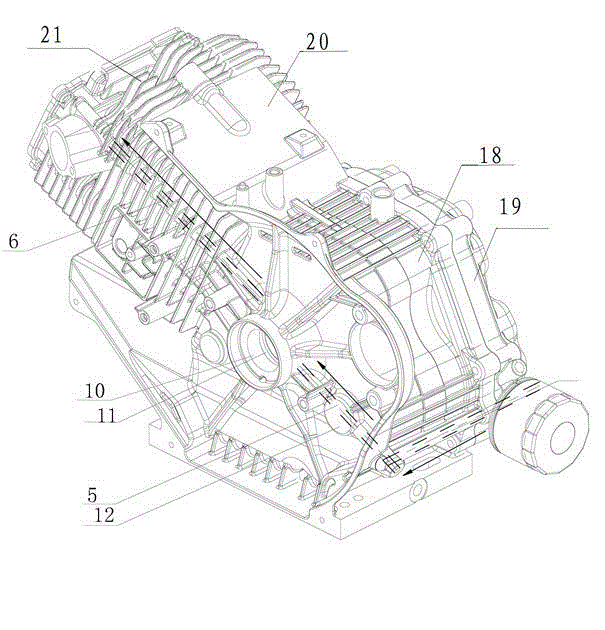

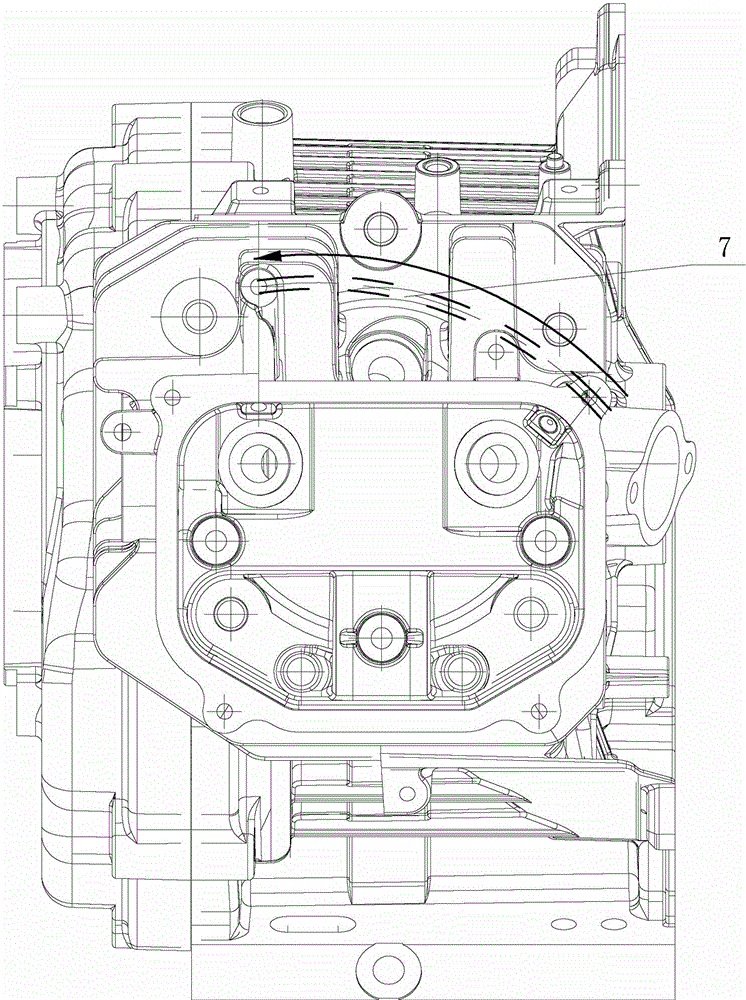

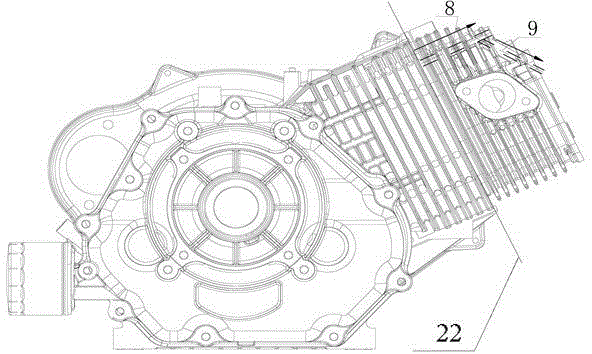

Universal single-cylinder large-displacement gasoline engine device

ActiveCN104564332AReduce the temperatureReduced tightnessMachines/enginesPressure lubrication with lubrication pumpCylinder headGasoline

The invention discloses a universal single-cylinder large-displacement gasoline engine device which comprises a box body, a box cover and a cylinder head which are connected with one another, wherein a crankshaft is in direct revolute-pair connection with the box body and the box cover; oil ducts communicated with one another are arranged on the box body, the box cover and the cylinder head; the oil ducts in the box body and the box cover respectively reach a rotation pair formed by the crankshaft, the box body and the box cover; a first branch oil duct and a second branch oil duct from which lubricating oil can flow out are arranged at the rotation pair; the first branch oil duct is communicated with an oil duct in the crankshaft to reach a crankshaft link; the second branch oil duct reaches the top of an air valve, a rocker arm and a push rod after being communicated with the oil duct in the cylinder head; and the oil ducts in the box body are simultaneously communicated with a balance shaft rotationally connected with the box body. The universal single-cylinder large-displacement gasoline engine device realizes diversification of universal engine products and remedies market shortage. More importantly, the universal single-cylinder large-displacement gasoline engine device can be used for completely replacing a double-cylinder engine with the same displacement. The universal single-cylinder large-displacement gasoline engine device is 30% lower than the double-cylinder engine in cost and can meet a hot market demand.

Owner:CHONGQING DAJIANG POWER EQUIP MFG

Steel-PVA fiber toughness concrete combined bridge deck structure and construction method thereof

PendingCN110106785AInsufficient control stiffnessCoordinated Control Method for Structural DeformationBridge structural detailsFiberSurface layer

The invention discloses a steel-PVA fiber toughness concrete combined bridge deck structure and a construction method thereof. The combined bridge deck structure comprises a steel bridge panel layer,a PVA fiber toughness concrete layer, a bonding layer and an asphalt concrete surface layer; a plurality of shear bolt nails are fixed to the steel bridge panel layer; and the PVA fiber toughness concrete layer is laid on the steel bridge panel layer, and internally provided with longitudinal and transverse double-layer reinforcing meshes and chloroprene rubber cushion blocks which are laid out onthe steel bridge panel layer and used for supporting the longitudinal and transverse double-layer reinforcing meshes. The combined bridge deck structure has the advantages that the building height issmall, the light weight and high strength are achieved, bonding performance between all the combined layers is good, cooperative bearing of all the combined layers is uniform, deformation compatibility is easy to control, durability is good, anti-fatigue performance is good, and the impact effect of vehicles is small, and is particularly suitable for bridge deck pavement of large-span bridges.

Owner:ZHEJIANG UNIV OF TECH

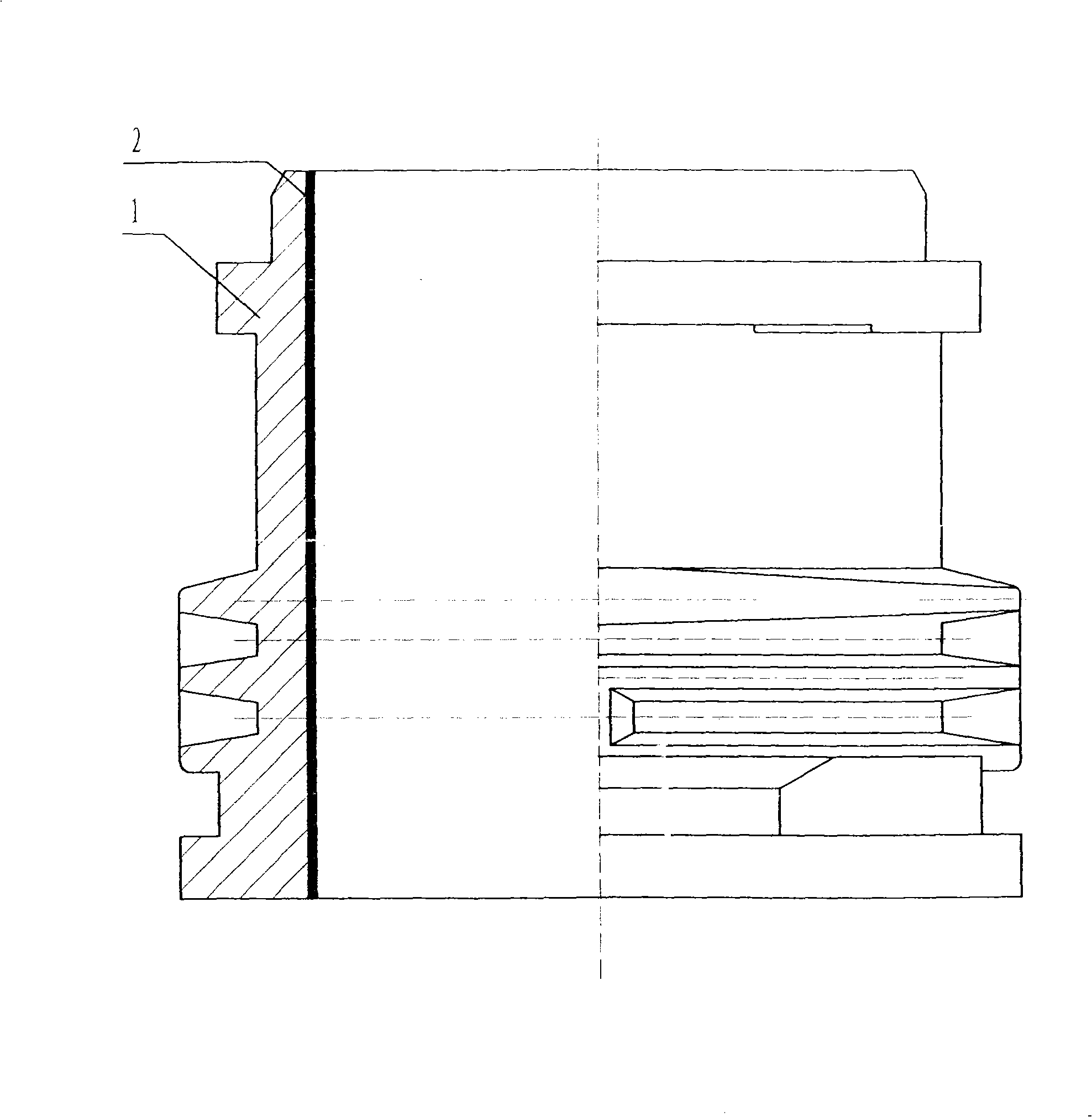

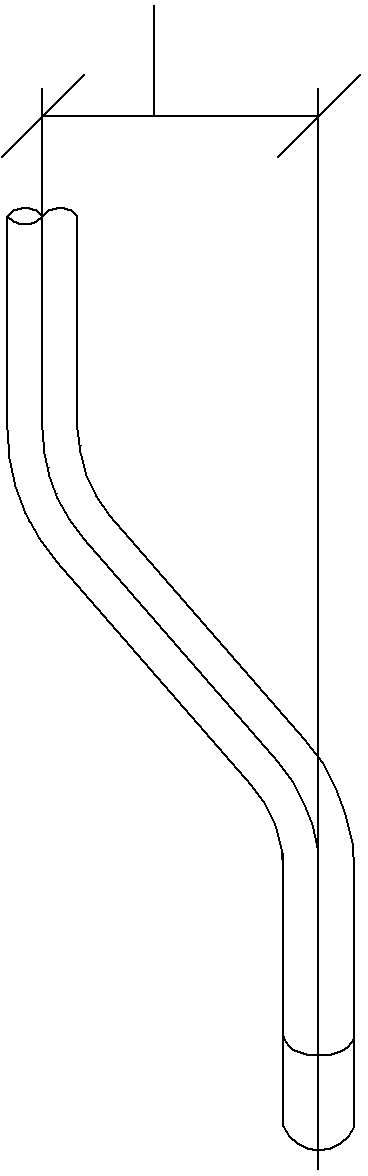

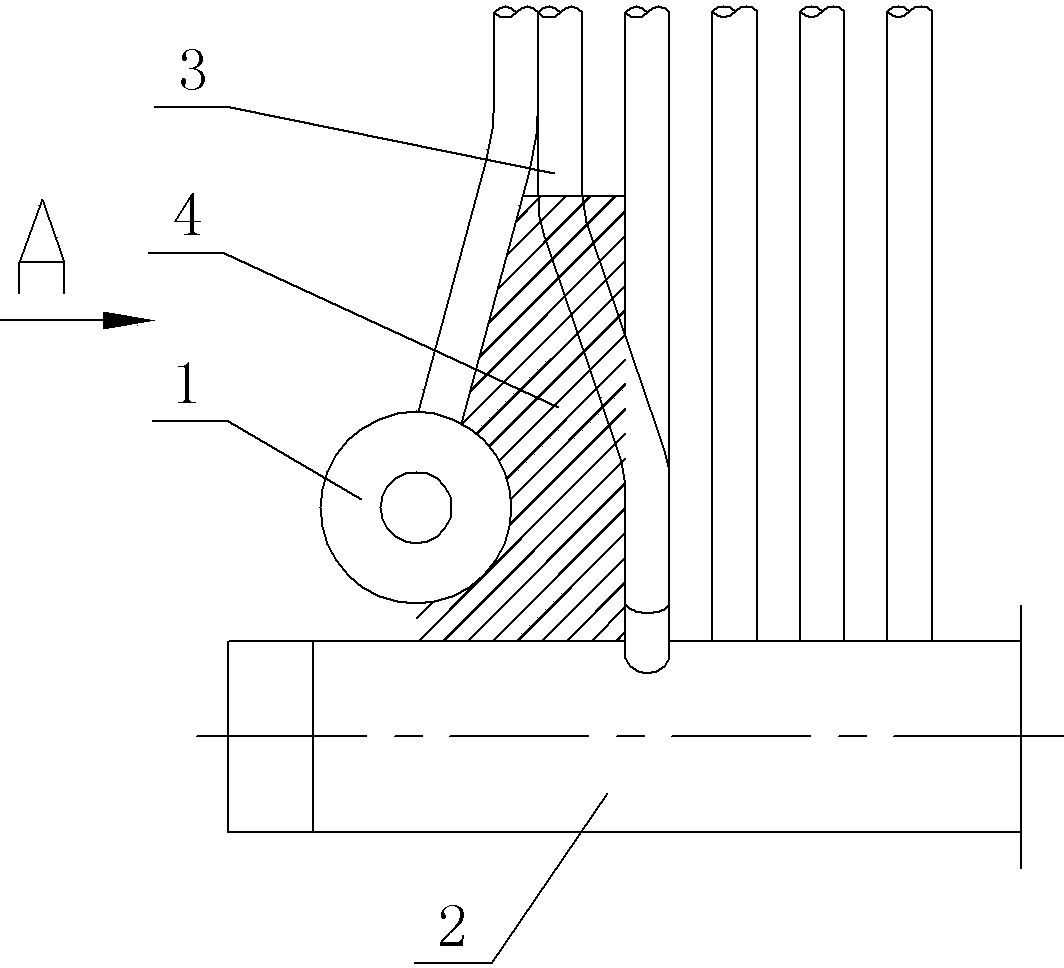

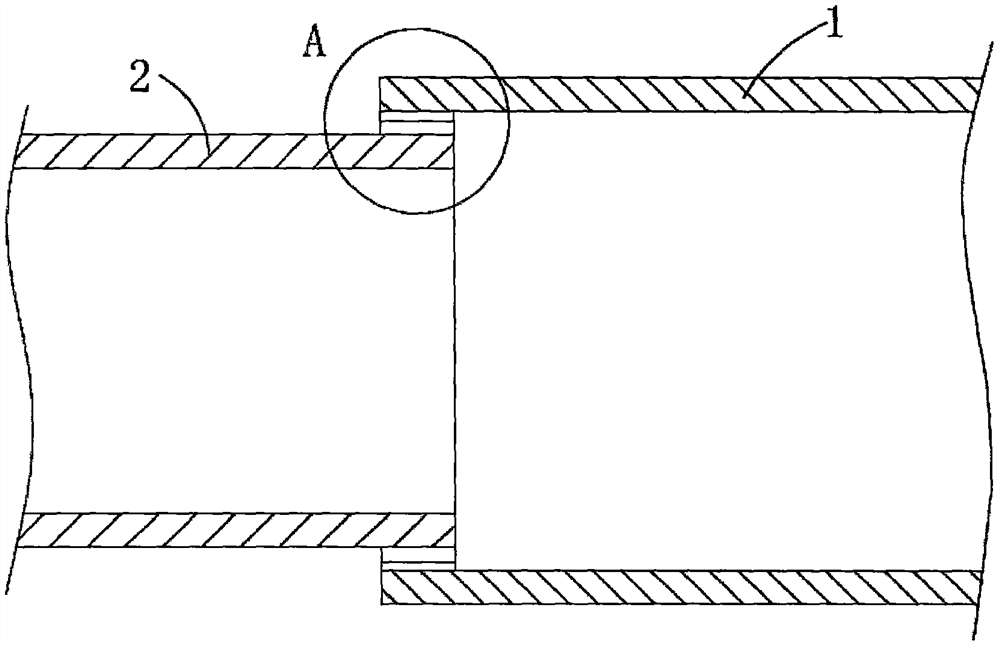

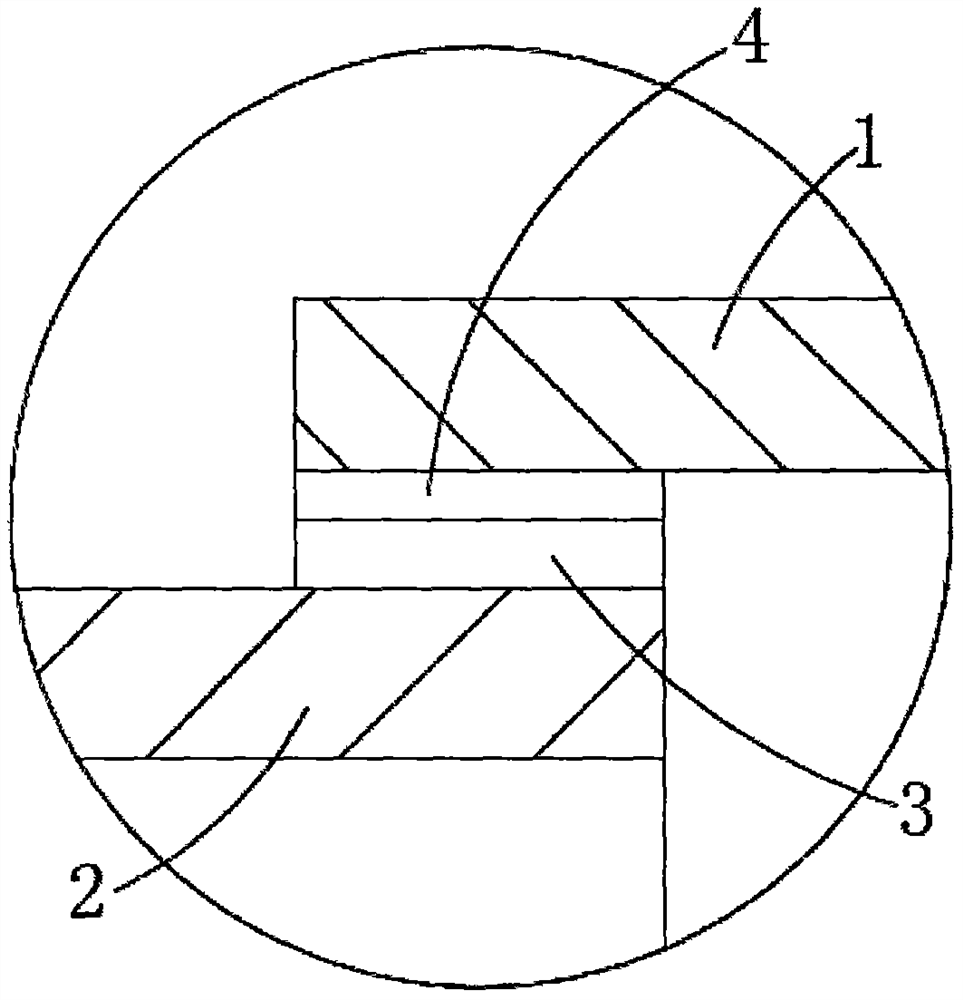

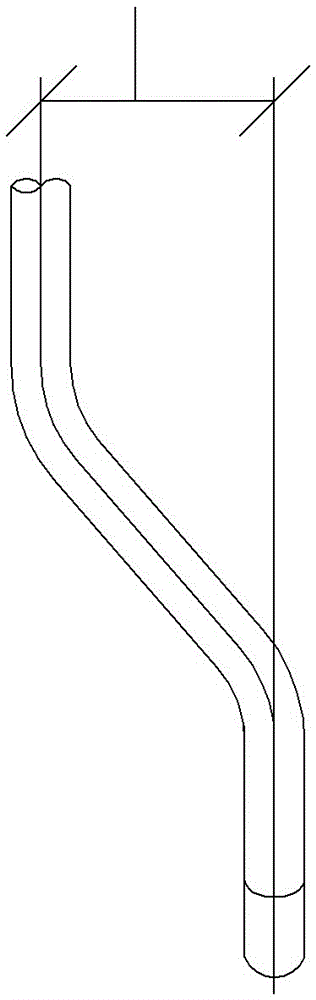

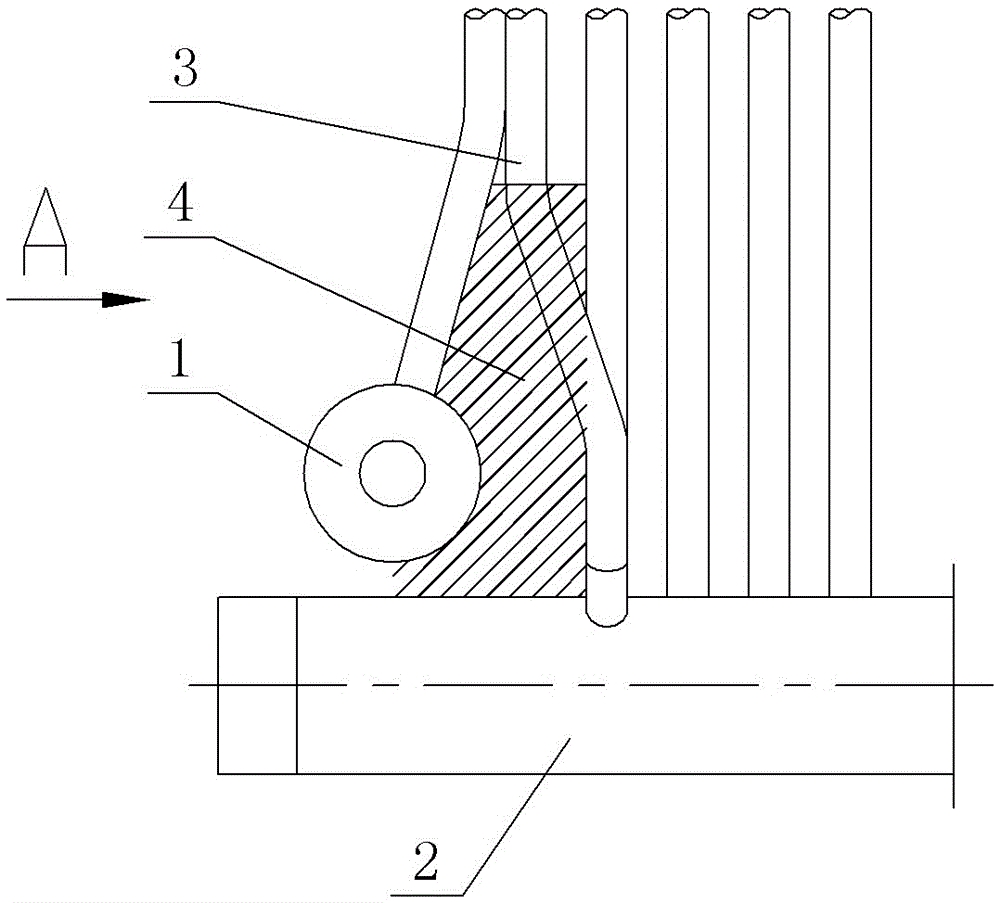

Arrangement structure for wall enclosure header of boiler

ActiveCN103453511AReduce usageRelieve welding stressFluid heatersBoiler drums/headersStructural engineeringCarbon steel

The invention provides an arrangement structure for a wall enclosure header of a boiler. The arrangement structure can eliminate welding stress and expansion stress between a sealing steel plate and a pipe, solve the problem that the sealing steel plate tears off the wall of the pipe due to the change of stress, ensure the normal use of the wall enclosure pipe and further ensure the normal use of the boiler. The arrangement structure comprises a front wall lower header, a side wall lower header, a side wall enclose elbow pipe and the sealing steel plate. The sealing steel plate is welded onto the front wall lower header, the side wall lower header and the side wall enclosure elbow to form an isolation structure. The arrangement structure is characterized in that the front wall lower header is positioned above the horizontal direction of the side wall lower header, the number of the side wall enclosure elbow is one, the horizontal distance of the side wall enclosure elbow is reduced to half of the original horizontal distance and the sealing steel plate is specifically a sealing steel plate which is made of carbon steel.

Owner:WUXI HUAGUANG BOILER

A connection structure between glass and Kovar and a low-temperature sintering method

ActiveCN108723632BHigh temperature and reliableNo residual stressWelding/cutting auxillary devicesAuxillary welding devicesSolder pasteKovar

Owner:北京天瑞星光热技术有限公司

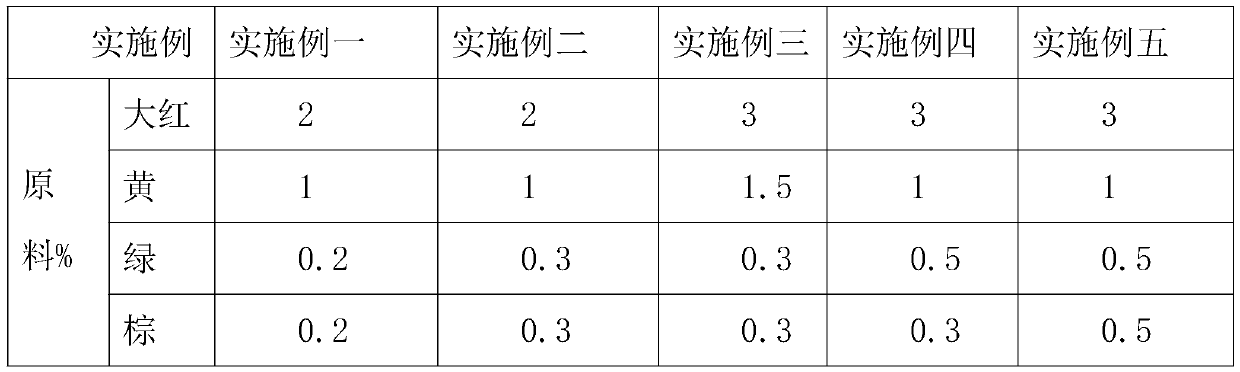

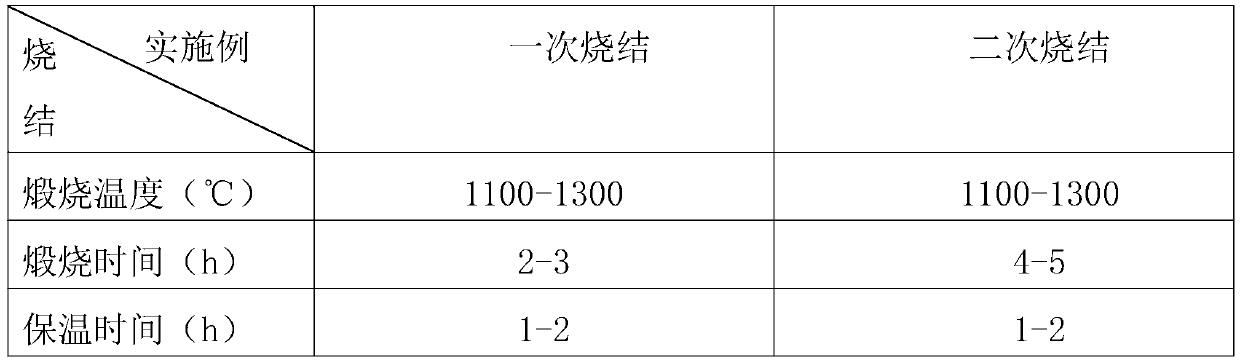

Imitation marble glaze heat-resistant porcelain formula and preparation method thereof

InactiveCN110028243ASame expansion coefficientAchieve decorative effectAlkali feldsparMaterials science

The invention discloses an imitation marble glaze heat-resistant porcelain formula which comprises the following raw materials in percentage by mass: 94.5-96.6% of a base material and 3.4-5.5% of an additive, wherein the base material is basic white glaze. According to the imitation marble glaze heat-resistant porcelain formula and the preparation method thereof, a ground glaze is prepared by adding a color base into spodumene, petalite and kaolin, then a multi-color marble color glaze is sprayed, and firing is conducted, thus the combination property is good, the expansion coefficients of a blank, the glaze and the sprayed glaze are consistent, the glaze does not crack due to shock, pores are avoided, the decoration covering property is good, and the qualification rate of products is greatly improved. The decorative effect of the ceramic imitation marble glaze is achieved, the attractiveness of the product is improved, and the requirements of vast consumers are met.

Owner:江西嘉顺瓷业有限公司

Glass and kovar connecting structure and low-temperature sintering method

ActiveCN108723632AHigh temperature and reliableNo residual stressWelding/cutting auxillary devicesAuxillary welding devicesCopper platingAdhesive

The invention discloses a glass and kovar connecting structure. The glass and kovar connecting structure comprises a high-boron solar heat collecting glass tube and a kovar alloy tube, wherein the kovar alloy tube is inserted into the high-boron solar heat collecting glass tube, a micron kovar soldering paste layer is arranged at the joint on the outer side of the kovar alloy tube, a copper plating layer is arranged at the joint on the inner side of the high-boron solar heat collecting glass tube, and the micron kovar soldering paste layer is connected with the copper plating layer and prepared from components in percentage by mass as follows: 60wt%-70wt% of Fe-Co-Ni alloy particles, 20wt%-30wt% of an adhesive and 5wt%-10wt% of 90%-95% ethanol. The technical scheme has beneficial effects as follows: with the creative application of a low-temperature sintering method, micron kovar soldering paste is taken as an intermediate material, glass-kovar sealing connection is realized, and the structure is reliable at high temperature, free of residual stress and good in mechanical property.

Owner:北京天瑞星光热技术有限公司

Method for preparing and loading sample before solid nuclear magnetism of gas hydrate

ActiveCN109187612AImprove stabilityEfficiencyAnalysis using nuclear magnetic resonanceDecompositionPhysical chemistry

The invention discloses a method for preparing and loading a sample before solid nuclear magnetism of gas hydrate. According to the method, the sample in efficiently and rapidly prepared, so that thesample is protected to the maximum extent; a lid is firm and unlikely to be damaged, the solid nuclear magnetism test of the gas hydrate can be rapidly and efficiently finished, the accurate structural information of the gas hydrate and the structural and constitutional change information of the gas hydrate in the generation and decomposition processes can be acquired, and the generation and decomposition mechanisms of the gas hydrate can be explored, so that the problems that the lid of a sealing rotor is damaged due to the frosting in the sample preparation process of liquid nitrogen, and the nuclear magnetism test cannot be finished are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Tracing-type plastic pipeline

The invention relates to a tracer plastic pipeline, which belongs to the technical field of pipeline processing. In order to solve the existing problem of easy leakage, a tracer-type plastic pipe is provided, the plastic pipe is made of plastic material, and a metal carrier for installing RFID chips is embedded in the pipe wall of the pipe. The plastic material mainly includes the weight parts of the following components: polyethylene: 70-85; nitrile rubber: 5.0-8.0; sulfonate modified polyol: 0.1-0.2; Propylene: 10~13; filler: 5.0~6.0; nucleating agent: 2.0~4.0; bamboo fiber: 4.0~8.0. The invention can improve the heat-resistant stability of the material, and can make the expansion coefficient of the material reach the range of the expansion coefficient of common metals, so that the expansion coefficients between the two can basically achieve the same effect.

Owner:YONGGAO CO LTD

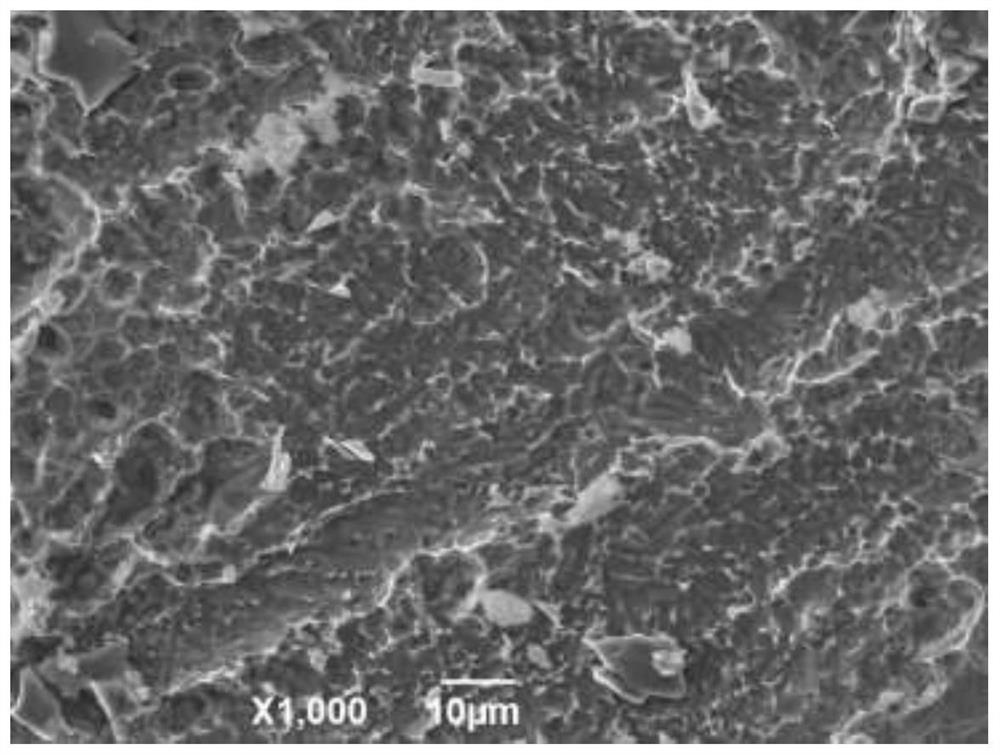

Efficient silicon carbide corundum rare earth ceramic composite grinding wheel and manufacture method thereof

The invention relates to an efficient silicon carbide corundum rare earth ceramic composite grinding wheel which comprises the following raw materials in percentage by weight: 30-75wt percent of silicon carbide abrasive, 25-70wt percent of corundum abrasive, 12-22wt percent of rare earth ceramic and 3.5-8wt percent of normal-temperature binding agent. The composite grinding wheel is manufactured by the steps of calcining, ball-milling, blending, moulding, drying, sintering, and the like. The grinding wheel of the invention has the advantages of high grinding force for grinding a difficult grinding material, sharp grains, high self sharpening, shedding in time of blunt grinding grains and no burning on workpieces. Compared with the traditional single grinding material common ceramic binding agent grinding wheel, the efficient silicon carbide corundum rare earth ceramic composite grinding wheel obviously improves the grinding efficiency; and compared with a grinding wheel adopting an expensive superhard grinding material (artificial diamond or CBN (Cubic Boron Nitride)), the efficient silicon carbide corundum rare earth ceramic composite grinding wheel obviously reduces the grindingcost and has wider adaptation and favorable economic and social benefits.

Owner:FUZHOU SHUANGYI GRINDING WHEEL +1

Copper-nickel-silver brazing paste and preparation method thereof

ActiveCN111482734BSolve the problem of brazing strengthHigh strengthWelding/cutting media/materialsSoldering mediaSlurryThermal conductivity

The invention discloses a copper-nickel-silver brazing paste and a preparation method thereof. The invention adopts copper-nickel-silver with more stable alloy properties as the main base material, and prepares a copper-nickel-silver brazing paste through the cooperation of brazing flux. Soldering paste, which can meet the needs of brazing heat dissipation materials and external parts based on copper, silver, nickel and other base materials. The copper-nickel-silver brazing paste obtained in the present invention has high brazing joint strength after welding , The thermal conductivity and expansion coefficient are consistent with the heat dissipation substrate, which can effectively avoid poor product performance caused by differences in expansion coefficient.

Owner:浙江力强科技有限公司

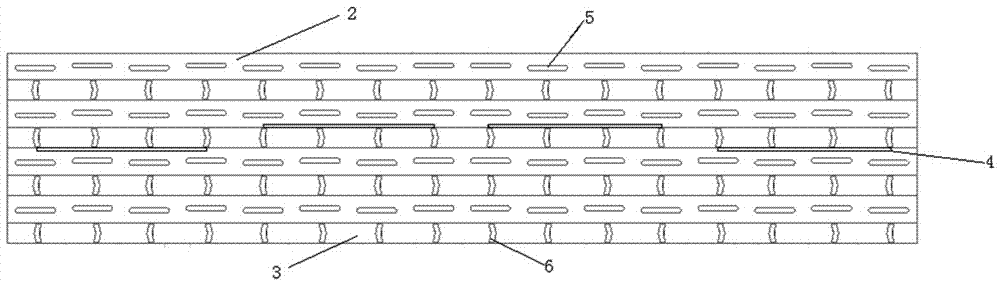

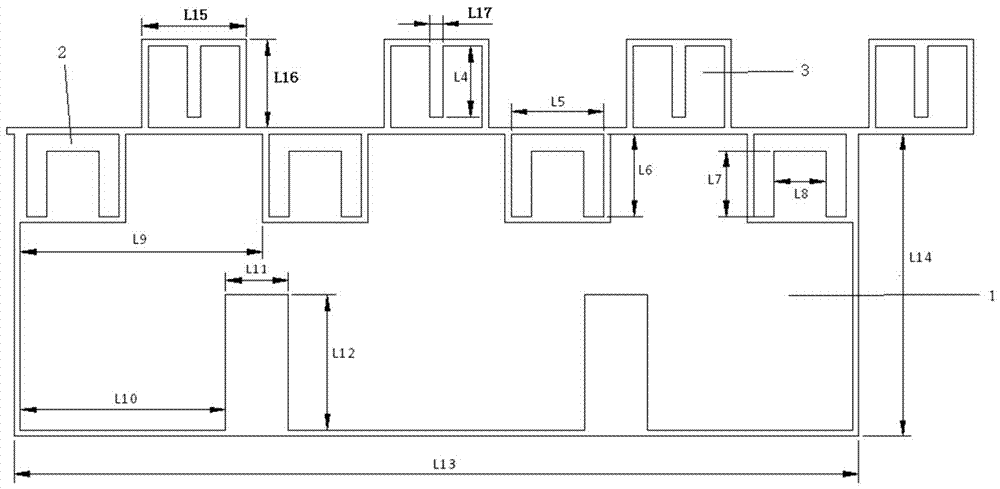

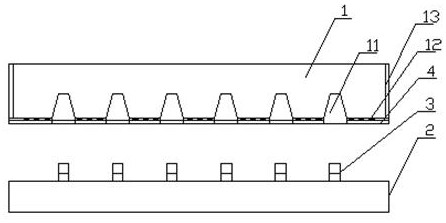

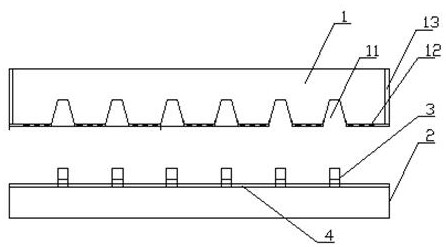

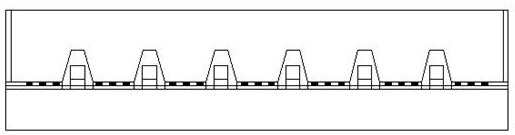

Backlight assembly

PendingCN113960712AGood optical performanceEven contactPlanar/plate-like light guidesLight guideEngineering

The invention relates to a backlight assembly which comprises a light guide plate, a substrate and a plurality of light sources. A plurality of grooves are formed in the incident surface of the light guide plate, a first reflecting layer is arranged on the peripheral side surface of the plate body, and light guide structures are arranged at the rest parts of the grooves in the incident surface; conductive circuits are sequentially arranged on the substrate; heat-conducting reflecting layers attached to the outer side of the light guide structure are further arranged at the rest parts of the grooves in the light incident surface, or a heat-conducting reflecting layer attached to the outer sides of the conductive circuits is arranged on the substrate; the substrate is attached to the light incident surface of the light guide plate, so that the light sources are arranged in the grooves. The heat conduction and heat dissipation layer is used for fully conducting heat generated by working of the light source to the substrate, the hot spot area is flattened, and the substrate transversely and longitudinally uniformly transfers heat to the outside, so that the backlight assembly has a good heat dissipation effect while achieving lightening and thinning; and the light source, the backlight assembly and other parts connected with the backlight assembly are ensured to be in a proper working temperature environment.

Owner:南通创亿达新材料股份有限公司

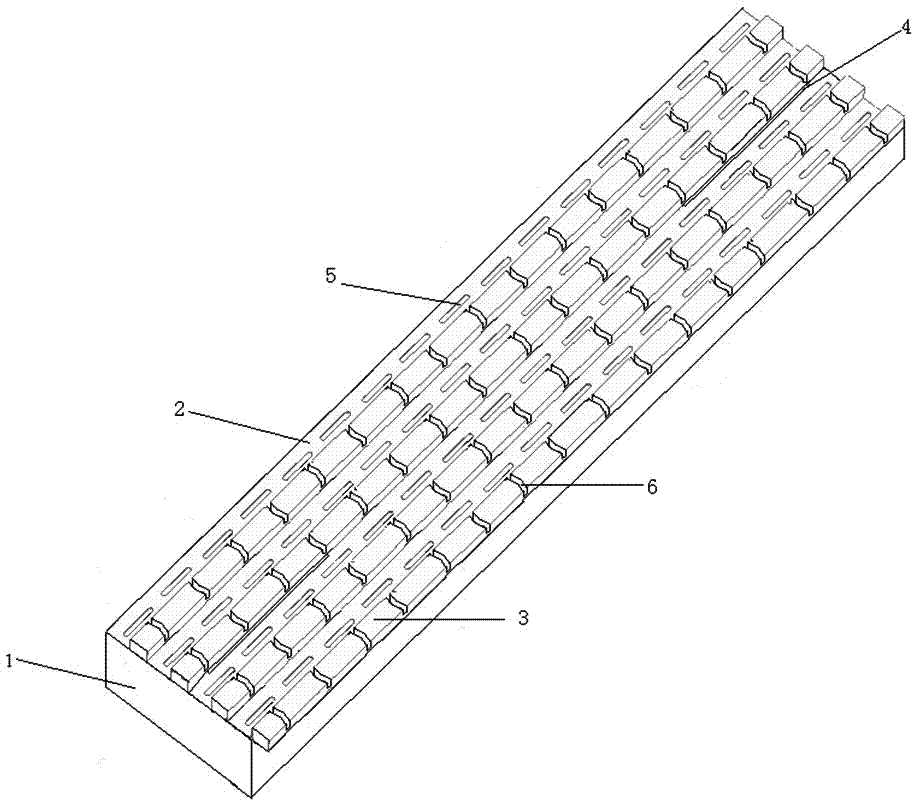

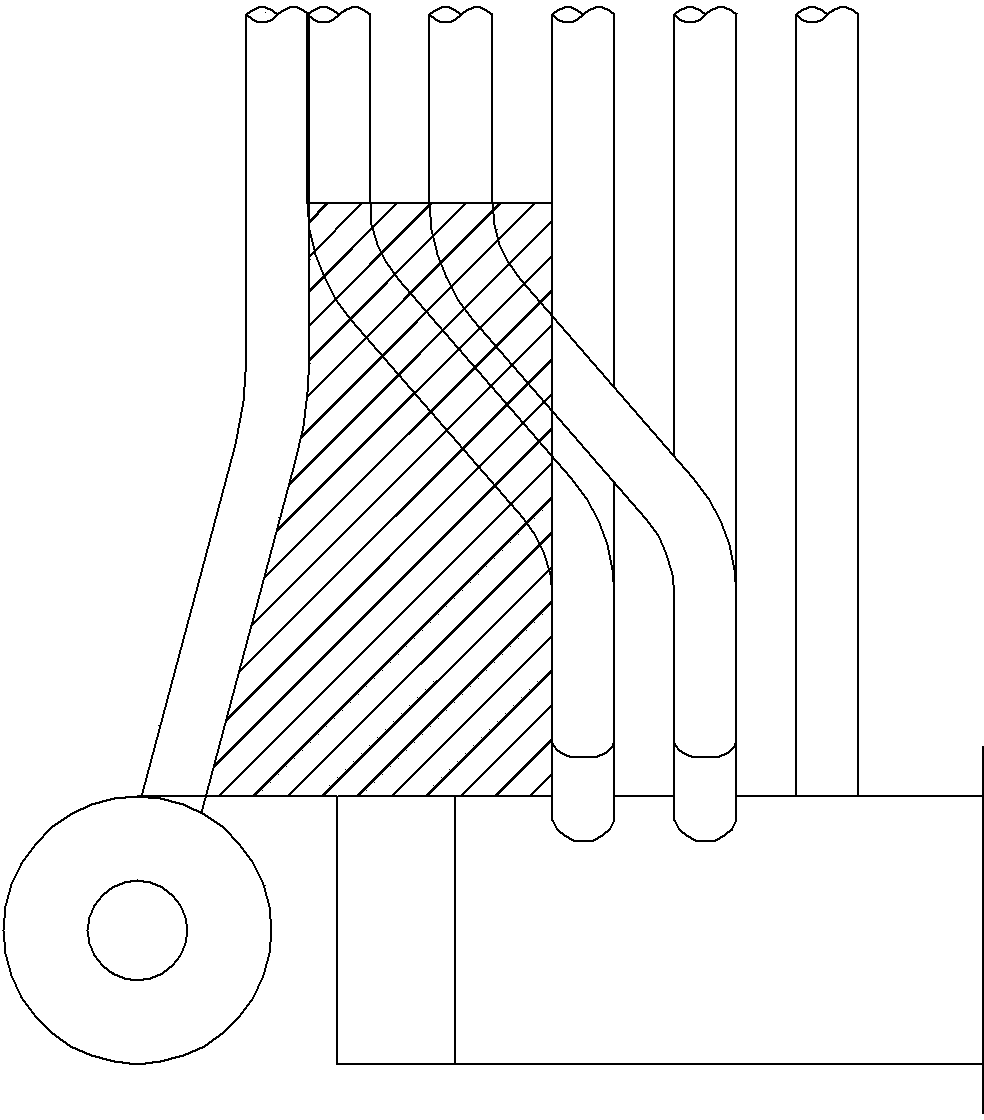

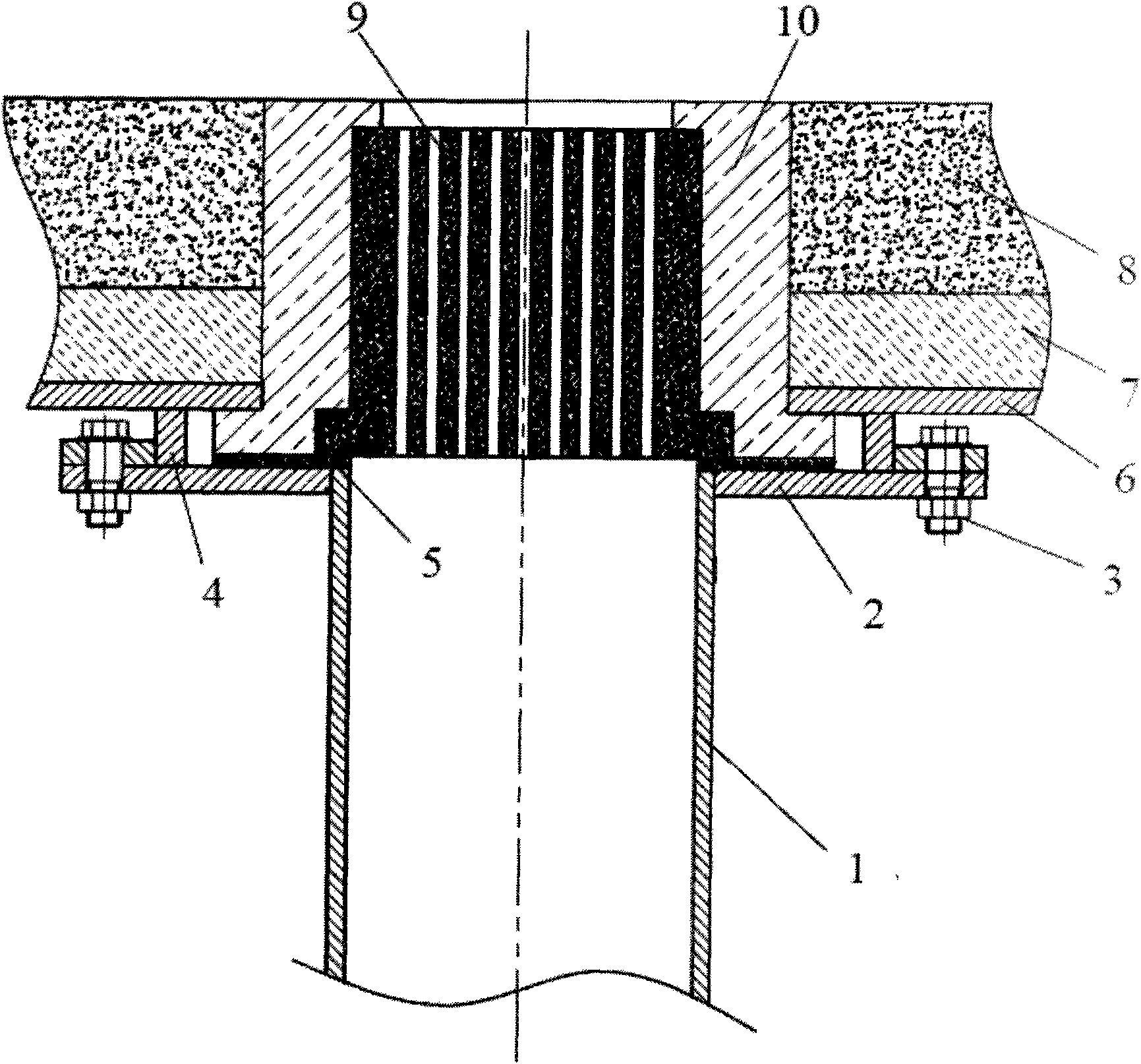

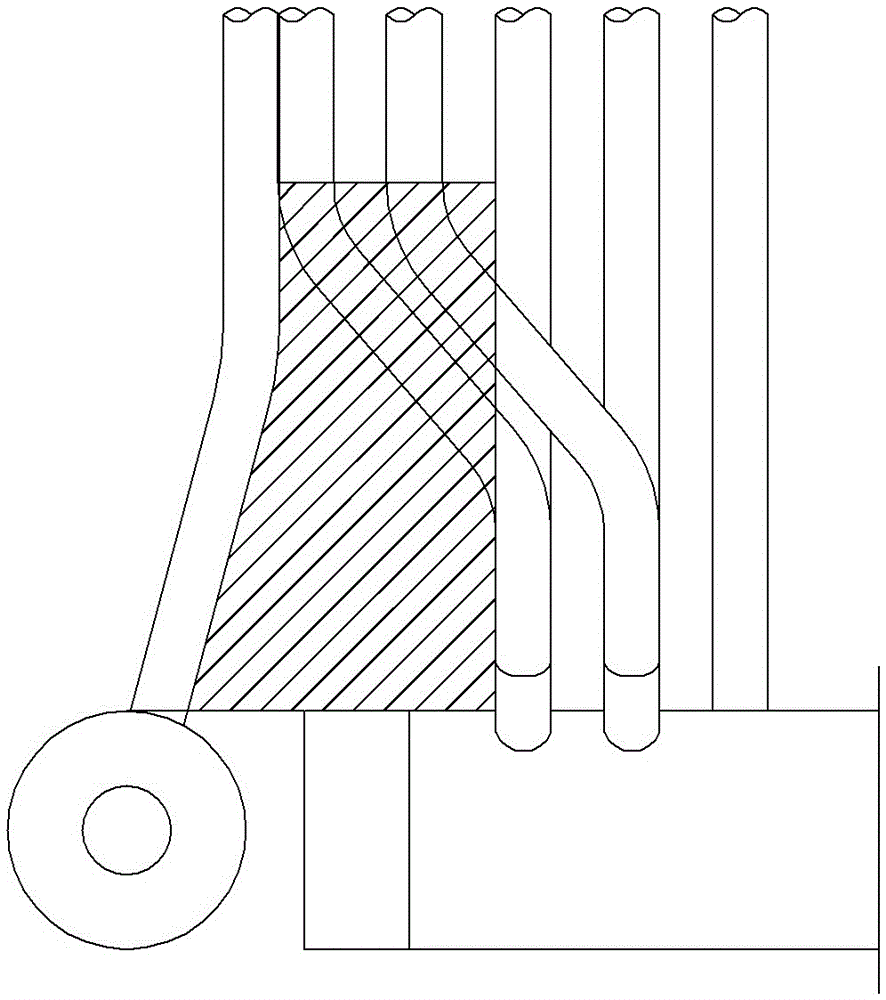

Combined air supply nozzle, rotary kiln and preparation method of rotary kiln

ActiveCN102235821BEasy to installEasy to replaceRotary drum furnacesCombustible gasProcess engineering

The invention discloses a combined air supply nozzle, a rotary kiln and a preparation method thereof, which are mainly designed to improve the defects of the existing air supply nozzle such as short service life and inconvenient installation and replacement. The combined air supply nozzle of the present invention is composed of a nozzle cover and a nozzle core; wherein, the nozzle cover is a tubular structure, and the inner cavity of the tubular structure is adapted to the outer dimension of the nozzle core; the nozzle core is placed At least one through hole penetrating through the two ends of the nozzle core is provided in the nozzle sleeve and in its core. The nozzle core and nozzle cover of the present invention are pre-extruded and then fired at high temperature, which are relatively easy to install and replace, and their strength and practical performance are not limited by the kiln curve. In addition, outside air is ejected through multiple through holes in the nozzle core, which not only can better mix the air with the combustible gas in the kiln, but also can evenly burn the kiln temperature and reduce the temperature difference between the flame and the material.

Owner:HUATIAN ENG & TECH CORP MCC

A kind of Ru porcelain porcelain clay and preparation method thereof, Ru porcelain and preparation method thereof

The invention relates to the technical field of ceramics, in particular relates to Ru porcelain clay and a preparation method thereof, and also relates to Ru porcelain calcined with the Ru porcelain clay and a preparation method thereof. The Ru porcelain clay consists of 23 to 33 parts of Fengxue soil, 17 to 27 parts of Banpo soil, 10 to 25 parts of Tanggou soil, 8 to 20 parts of black soil, 5 to15 parts of quartz, 1 to 8 parts of sandstone, 0.5 to 2 parts of feldspar and 0.5 to 2 parts of alkaline ore. The Ru porcelain calcined with the Ru porcelain clay has excellent quality, compact porcelain body, high hardness and strong surface appearance, and when the Ru porcelain used as tableware and tea ware, remaining tea stains and oil stains are easy to clean, and practicability is enhanced.

Owner:王晟鸣 +1

An Arrangement Structure Used for Lower Header of Boiler Wall

ActiveCN103453511BReduce usageRelieve welding stressFluid heatersBoiler drums/headersStructural engineeringPackage boiler

The invention provides an arrangement structure for the lower header of the boiler cladding wall, which can eliminate the welding stress and expansion stress between the sealing steel plate and the pipe, solve the problem that the sealing steel plate tears the pipe wall due to the change of stress, and ensure Ensure the normal use of the boiler wall tube, and then ensure the normal use of the boiler. It includes the lower header of the front wall, the lower header of the side wall, the elbow of the side wall, and the sealing steel plate. The sealing steel plate is welded to the lower header of the front wall, the lower header of the side wall, and the elbow of the side wall. The isolation structure is characterized in that: the lower header of the front wall is located above the level of the lower header of the side wall, the bend of the side wall is one, and the horizontal distance of the bend of the side wall is reduced to the original Half of the sealed steel plate is specifically a carbon steel sealed steel plate.

Owner:WUXI HUAGUANG BOILER

Homogenic inorganic membrane tube and preparation method thereof

ActiveCN103170252BUniform diameterReduce weightSemi-permeable membranesCentrifugal forceMembrane tubulation

The invention relates to a preparation method of a homogenic inorganic membrane tube, belongs to the technical field of inorganic membranes and relates to a preparation method of inorganic membrane tubes and membrane tubes thereof. The method comprises the following steps of: 1) screening homogenic base materials with uniform or same particles in size; 2) uniformly mixing base materials with water and water glass to form an inorganic membrane tube raw material; 3) filling the inorganic membrane tube raw material to a centrifugal casting inorganic membrane tube machine and manufacturing a membrane forming tube by centrifugal force; and 4) demoulding, sintering and cooling to form. The homogenic inorganic membrane tube provided by the invention is simple to manufacture and free from drying and demoulding, so that the production efficiency is greatly improved and the production cost is lowered. The inorganic membrane tube products prepared by the invention are consistent in filter layers, and the filter precision of the tube products washed and damaged is still maintained consistent.

Owner:GUANGDONG INST OF ENG ENERGY SAVING & EMISSION REDUCTION TECH

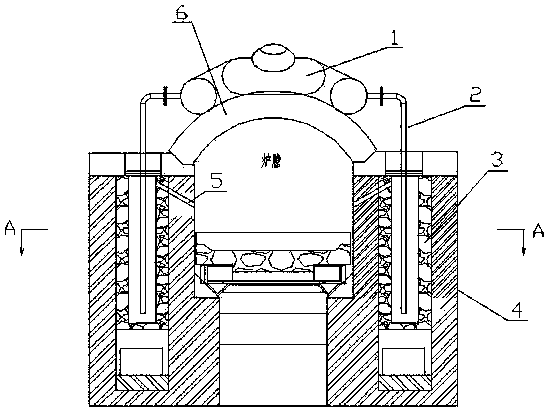

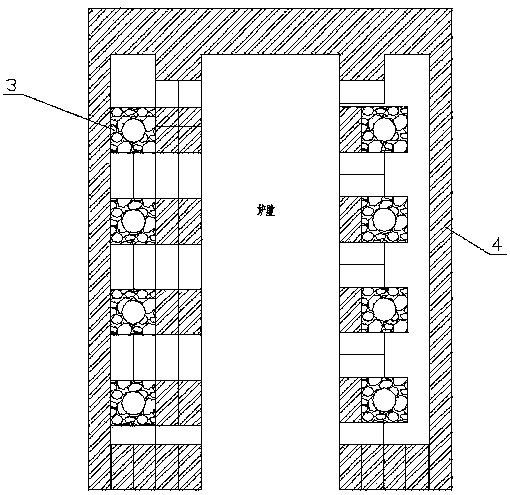

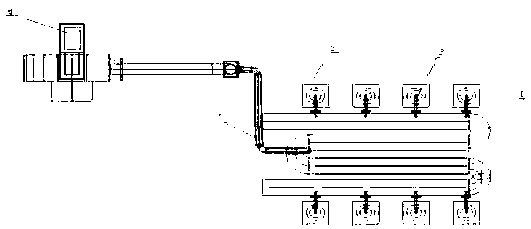

Built-in cremator heat exchanger

ActiveCN105650643BNo damageImprove incineration effectCremation furnacesIndirect carbon-dioxide mitigationBogiePlate heat exchanger

Owner:沈阳顺天意机械有限公司

Method for plating gold on surface of titanium alloy

The invention provides a method for plating gold on the surface of a titanium alloy. The method comprises the following steps that S1, a titanium alloy matrix is pretreated; s2, preparing a transition nickel layer; and S3, preparing an electrogilding layer. According to the method for plating gold on the surface of the titanium alloy, the acid etching procedure is added in the front oil removal process of the titanium alloy, then the surface roughness of the titanium alloy base material is increased through hydrochloric acid activating treatment, and then the surface of the titanium alloy base material is coated with the nickel intermediate transition layer and the surface gold layer; and hydrogen removal treatment and low-temperature heat treatment are continued after plating, so that a solid solution is formed between the plating layer and the substrate. Due to the fact that the thermal expansion coefficients of the plating layer and the base body are different, the gap between the plating layer and the base body is large, nickel ions and gold ions in the plating layer migrate in the heat treatment process, a thick diffusion layer can be formed between the plating layer and the base body, the expansion coefficients of the plating layer and the base body tend to be consistent, and finally the gap between the plating layer and the base body becomes small at high temperature. And a metal bond is formed between the coating and the substrate, so that the coating binding force is improved.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com