Homogenic inorganic membrane tube and preparation method thereof

An inorganic membrane and manufacturing method technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of complex process, unstable flow rate, inconsistent fluid outflow, etc., achieve uniform particle size and improve production. Consistent effect of efficiency and filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

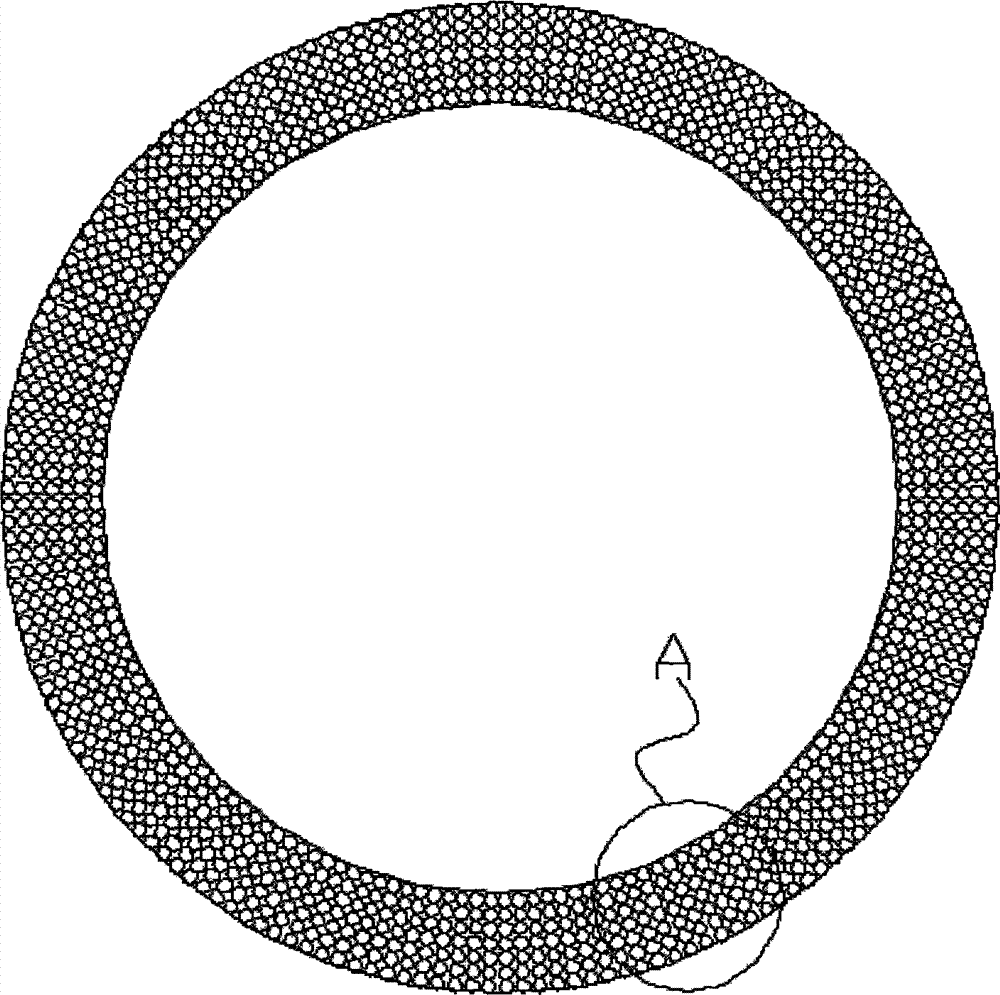

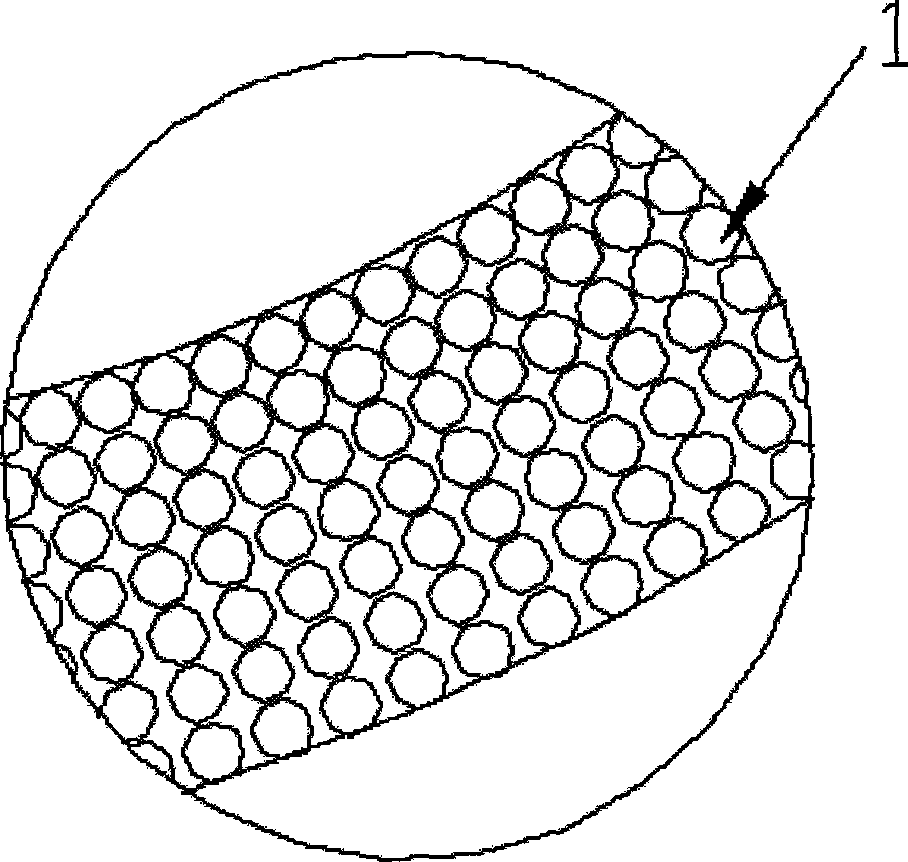

[0019] like figure 1 and figure 2 For the homogeneous inorganic membrane tube shown, the inorganic membrane tube has a diameter of 5-300mm, a length of 10-3000mm, a wall thickness of 1-20mm, and a membrane hole radius of 0.1-10um. The particle size of the inorganic base material 1 of the inorganic membrane tube is uniform or the same, and the particle size of the base material 1 is 0.2um-100um. Specifically: the particle size of the base material 1 of the inorganic membrane tube is 0.2um, 1um, 1.5um, 2um, 20um, 30um, 40um, 50um, 60um, 70um, 80um, 90um or 100um, according to the quality required by the fluid Screen the size of the particle size of the base material of the membrane tube. If the requirements for fluid separation, clarification, and sterilization are high, it is necessary to screen the base material with a small particle size.

[0020] The preparation method of above-mentioned homogeneous inorganic membrane tube is:

[0021] The weight ratio of raw materials f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com