A kind of Ru porcelain porcelain clay and preparation method thereof, Ru porcelain and preparation method thereof

A technology of Ru porcelain and porcelain clay, which is applied in the field of ceramics, can solve the problems not related to the cleaning of Ru porcelain tableware, and achieve the effect of moderate heat retention, high hardness and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

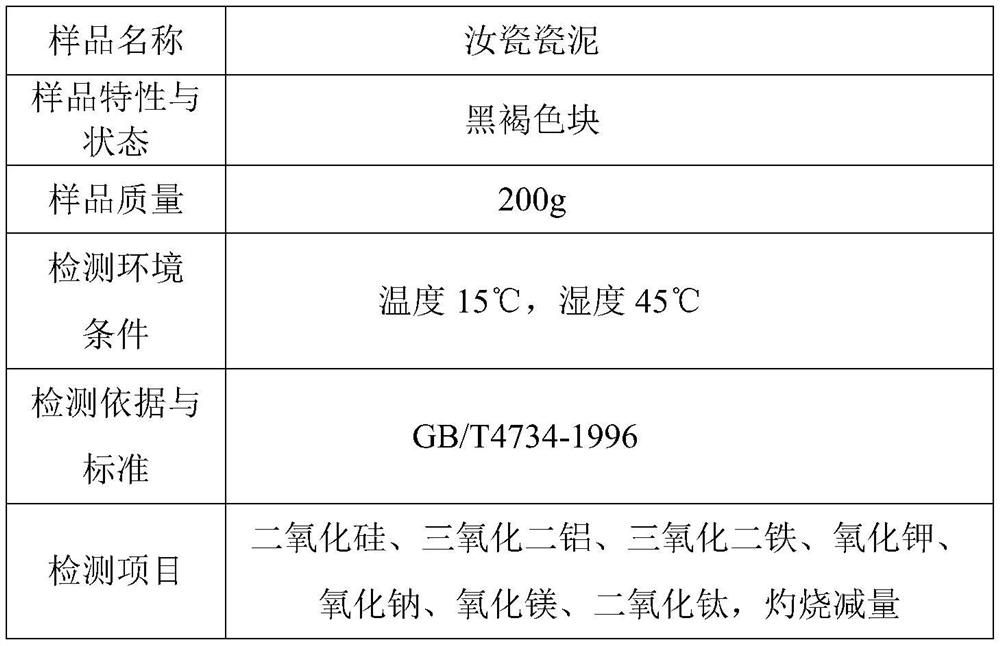

Image

Examples

Embodiment 1

[0034] The Ru porcelain porcelain clay of the present embodiment comprises the following components by weight: 28 parts of Fengxue soil, 22 parts of Banpo soil, 22 parts of Tanggou soil, 12 parts of black wool soil, 10 parts of quartz powder, 3.5 parts of sandstone , 1.2 parts of feldspar, 1.3 parts of soda stone.

[0035] The preparation method of the Ru porcelain porcelain clay of the present embodiment may further comprise the steps:

[0036] (1) Select high-quality wind cave soil, banpo soil, Tanggou soil and black wool soil raw materials, and after selection, bleaching and crushing, put them into the wet ball mill with quartz powder, sandstone, feldspar and soda stone according to the above weight ratio Inside, according to the weight ratio of raw materials: ball: water 1:1.5:1, add water, ball mill for 19 hours, and stop grinding when the fineness of the mud reaches 2% of the sieve of the million-hole sieve to obtain the slurry;

[0037] (2) Put the slurry through an 80...

Embodiment 2

[0050] The Ru porcelain porcelain clay of the present embodiment comprises the following components by weight: 33 parts of Fengxue soil, 27 parts of Banpo soil, 20 parts of Tanggou soil, 9 parts of black wool soil, 8 parts of quartz powder, and 1 part of sandstone , 1 part of feldspar, 1 part of soda stone.

[0051] The preparation method of the Ru porcelain porcelain clay of the present embodiment comprises the following steps:

[0052] (1) Select high-quality wind cave soil, banpo soil, Tanggou soil and black wool soil raw materials, and after selection, bleaching and crushing, put them into the wet ball mill with quartz powder, sandstone, feldspar and soda stone according to the above weight ratio Inside, add water according to the weight ratio of raw materials: balls: water 1:1.5:1, ball mill for 20 hours, and stop grinding when the fineness of the mud reaches 2% of the sieve of the million-hole sieve to obtain slurry;

[0053] (2) Put the slurry through an 80-mesh sieve, t...

Embodiment 3

[0061] The Ru porcelain porcelain clay of the present embodiment comprises the following components by weight: 23 parts of Fengxue soil, 17 parts of Banpo soil, 25 parts of Tanggou soil, 15 parts of black wool soil, 11 parts of quartz powder, and 5 parts of sandstone , 2 parts of feldspar, 2 parts of soda stone.

[0062] The preparation method of the Ru porcelain porcelain clay of the present embodiment comprises the following steps:

[0063] (1) Select high-quality wind cave soil, banpo soil, Tanggou soil and black wool soil raw materials, and after selection, bleaching and crushing, put them into the wet ball mill with quartz powder, sandstone, feldspar and soda stone according to the above weight ratio Inside, add water according to the weight ratio of raw materials: balls: water 1:1.5:1, ball mill for 20 hours, and stop grinding when the fineness of the mud reaches 2% of the sieve of the million-hole sieve to obtain slurry;

[0064] (2) Put the slurry through an 80-mesh s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com