A kind of porcelain clay special for wool porcelain/underglaze multicolored porcelain and preparation method thereof

A technology of underglaze multicolored porcelain and porcelain clay, which is applied in the field of ceramic products, can solve problems such as unsatisfactory bonding, high transparency, and easy breakage of the clay body, and achieve low cost, excellent porcelain quality, and good transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

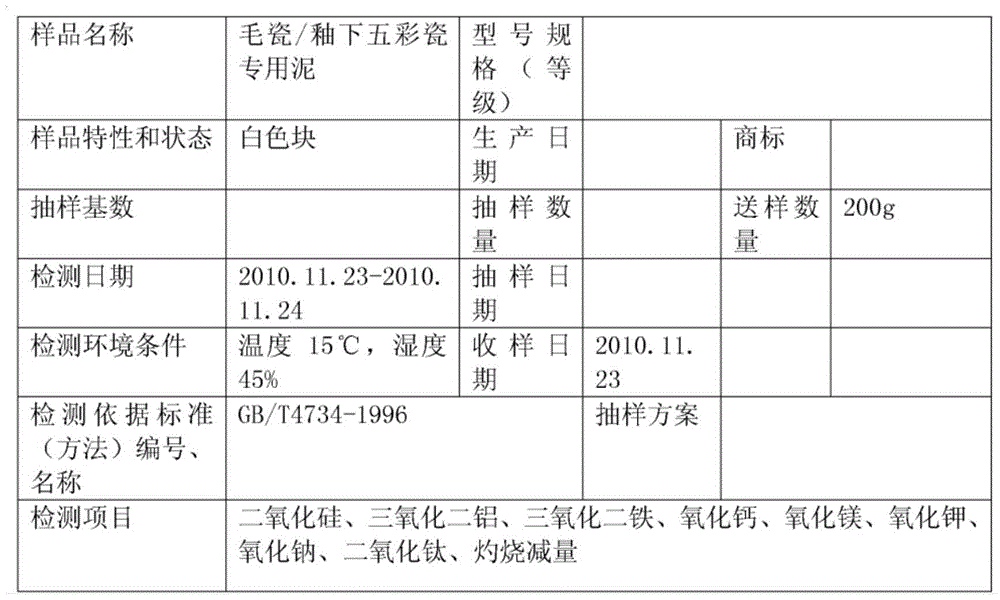

Image

Examples

Embodiment 1

[0028] Get the following weight percentage mud raw material:

[0029] Prepare wool porcelain and underglaze multicolored porcelain mud according to the following formula (all raw materials are industrial grade): kaolin 55%, bauxite 5%, calcite 10%, quartz stone 10%, wollastonite 5%, albite feldspar 10% %, dolomite 5%, the sum of the component percentages is 100%.

[0030] Using conventional wet ball milling, put the above-mentioned raw materials in the weight ratio into a ball mill, then add water, the ratio of material: ball: water is 1:1.5:0.5, and ball mill for 18-20 hours to obtain a slurry. Slurry passes through a 300-mesh sieve, and is filtered with a stainless steel vibrating screen with a 350-mesh filter. The super-strong iron absorber is used to filter and absorb iron, and the iron is absorbed repeatedly for 3 times. The hydraulic K75 press is used to squeeze the mud, and the water content is between 24% and 26%. between. Use an all-stainless steel mud refining mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com