Copper-nickel-silver brazing slurry and preparation method thereof

A technology of silver brazing and copper-nickel-silver, which is applied in the field of copper-nickel-silver brazing paste and its preparation, can solve the problems of inconsistent thermal conductivity and expansion coefficient, accelerated creep aging of welded joints, and poor strength of brazed joints, etc. Achieve the effects of avoiding the difference in expansion coefficient, solving the problem of brazing strength, and improving service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

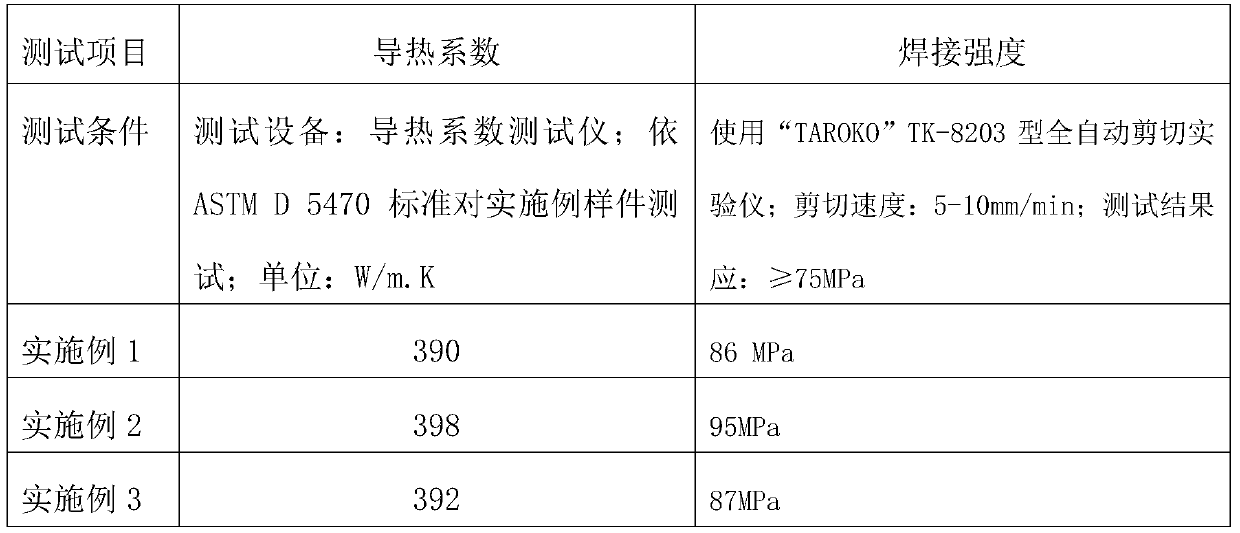

Examples

Embodiment 1

[0055] Step 1, the components of the second component brazing flux ① White mineral oil: 45Kg, ② Polyethylene glycol: 42.5Kg, ③ Polyisobutylene: 2.8Kg, ④ High-efficiency surfactant: 0.5Kg, ⑤ Phenolic Resin: 2.0Kg, ⑥ Tween: 1.5Kg, mix and heat to 90°C, after all the solid materials in it are melted, lower the temperature to room temperature, and then add materials ⑦ Sodium tripolyphosphate: 2.0Kg, ⑧ Potassium fluoroborate: 3.7 Kg, turn on the emulsification and stir for about 30 minutes to prepare the brazing additive paste;

[0056] Step 2, mixing the first component metal alloy powder with the brazing flux paste prepared in step 1, wherein the mass percentage of the metal alloy powder is 88%, and the mass percentage of the brazing flux paste is 12% %; then continue stirring for about 50 minutes by a star-type disperser to obtain the copper-nickel-silver brazing paste of the present invention.

Embodiment 2

[0058] Step 1, the component ① white mineral oil of the second component brazing flux:

[0059] 42.0Kg, ② polyethylene glycol: 43.0Kg, ③ polyisobutylene: 3.0Kg, ④ high-efficiency surfactant: 1.0Kg, ⑤ phenolic resin: 3.0Kg, ⑥ Tween: 2.0Kg, mix and heat to 90°C, wait for After all the solid materials are melted, lower the temperature to room temperature, then add the materials ⑦ sodium tripolyphosphate: 2.5Kg, ⑧ potassium fluoroborate: 3.5Kg, turn on the emulsification and stir for about 30 minutes, and prepare the brazing additive paste;

[0060] Step 2, mixing the first component metal alloy powder with the brazing flux paste prepared in step 1, wherein the mass percentage of the metal alloy powder is 87%, and the mass percentage of the brazing flux paste is 13% %; then continue stirring for about 50 minutes by a star-type disperser to obtain the copper-nickel-silver brazing paste of the present invention.

Embodiment 3

[0062] Step 1, the component ① white mineral oil of the second component brazing flux:

[0063] 48.0Kg, ② polyethylene glycol: 40.5Kg, ③ polyisobutylene: 2.5Kg, ④ high-efficiency surfactant: 0.5Kg, ⑤ phenolic resin: 2.0Kg, ⑥ Tween: 1.5Kg, mix and heat to 90°C, wait for After all the solid materials are melted, lower the temperature to room temperature, then add the materials ⑦ sodium tripolyphosphate: 2.0Kg, ⑧ potassium fluoroborate: 3.0Kg, turn on the emulsification and stir for about 30 minutes, and prepare the brazing aid paste;

[0064]Step 2, mixing the first component metal alloy powder with the brazing flux paste prepared in step 1, wherein the mass percentage of the metal alloy powder is 87%, and the mass percentage of the brazing flux paste is 13% %; then continue stirring for about 50 minutes by a star-type disperser to obtain the copper-nickel-silver brazing paste of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com