Combined air supply nozzle, rotary kiln and preparation method of rotary kiln

A rotary kiln and nozzle technology, applied in the field of combined air supply nozzle, rotary kiln and its preparation, can solve the problems of inconvenient construction and replacement of air supply nozzle, difficulty in matching the temperature rise curve, difficulty in guaranteeing performance, etc. The effects of air circulation, thermal expansion initiation temperature and expansion coefficient are consistent, and construction and replacement are convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

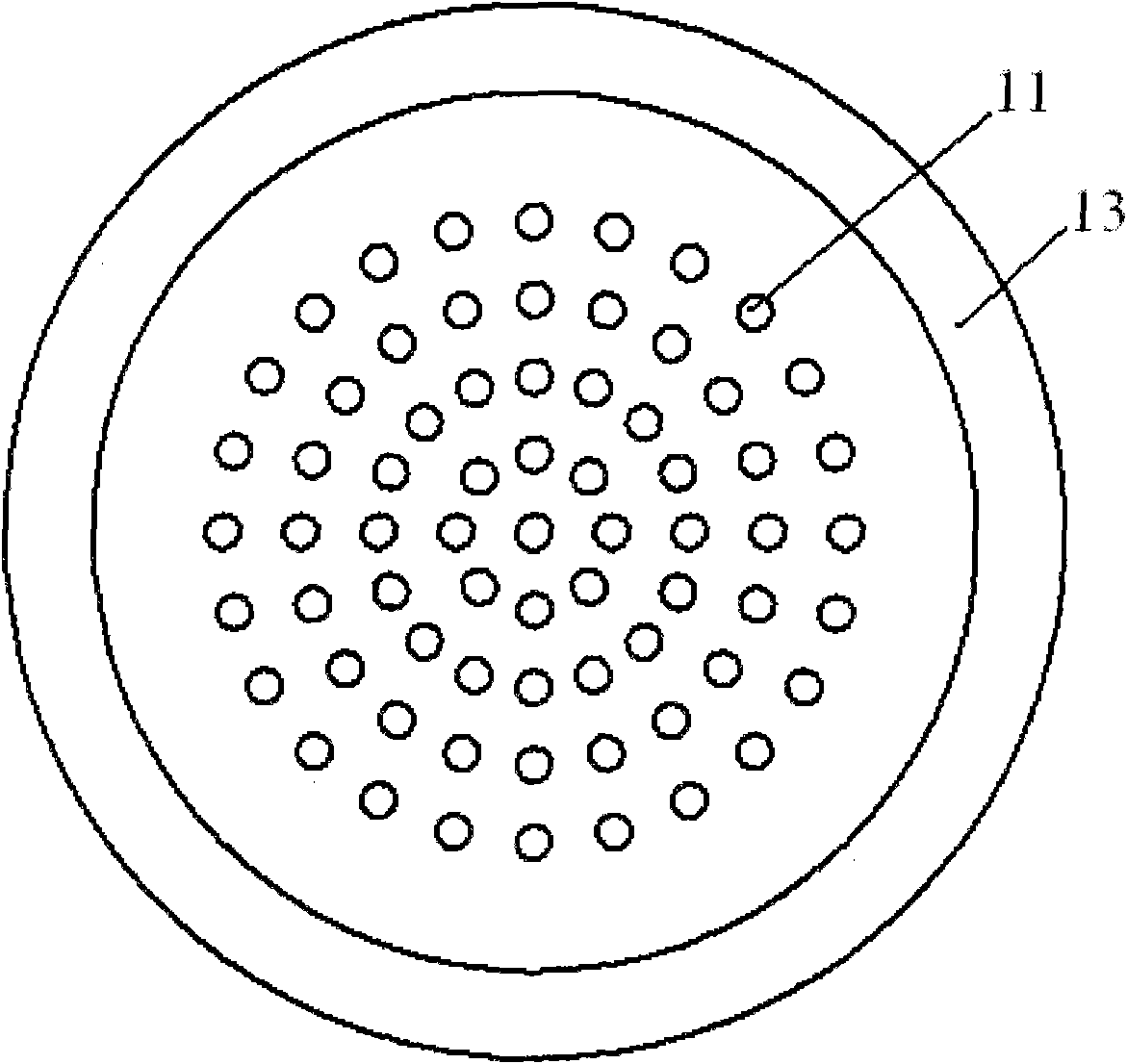

[0051] Such as Figure 4 and 5 As shown, the nozzle cover 10 has an inner annular boss 16 on the inner wall of the air outlet end, an annular groove 17 on the inner wall of the air inlet end and a first outer annular boss 15 on the outer wall;

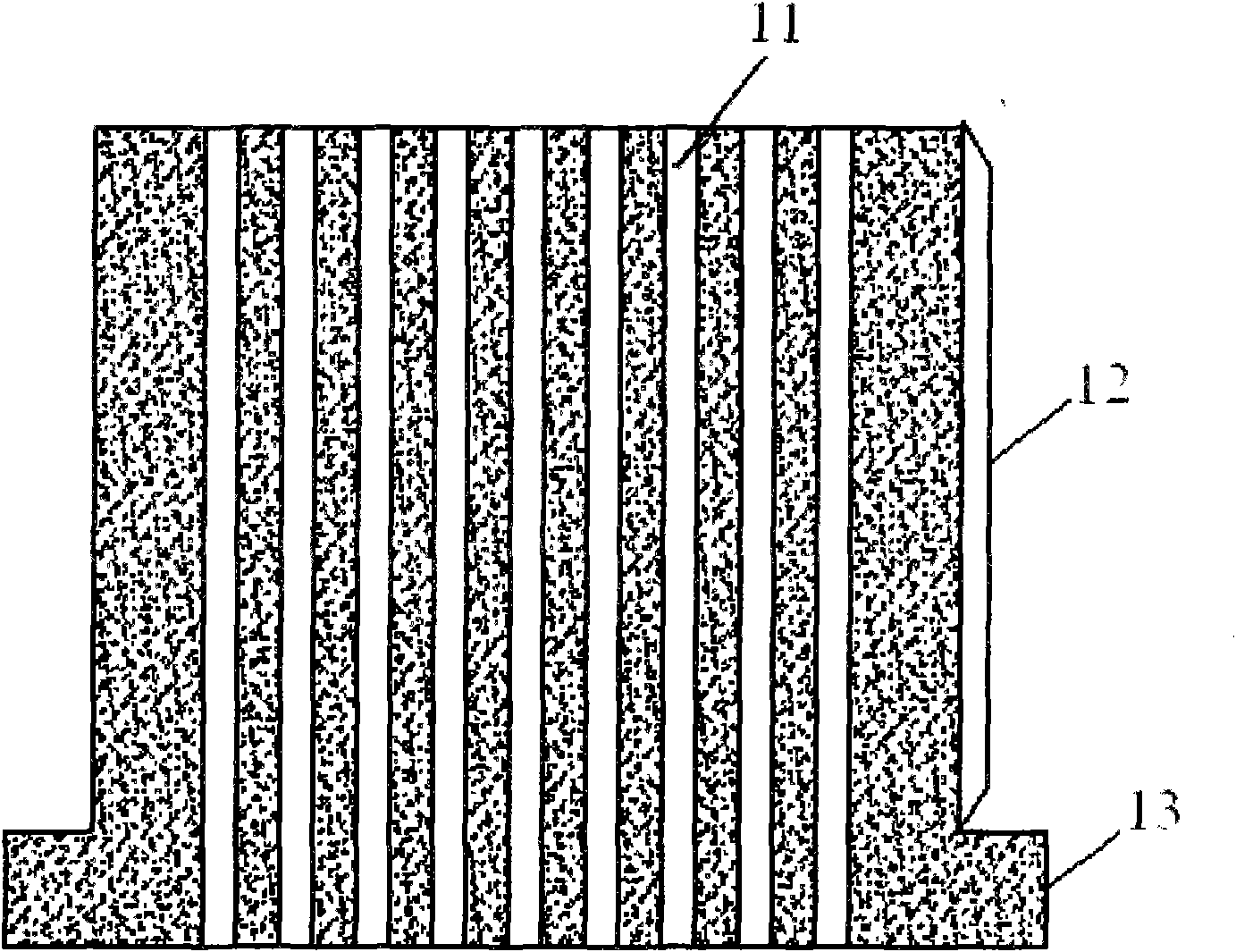

[0052] Such as figure 2 and 3 As shown, the nozzle core 9 is arranged in the nozzle cover 10, and the end surface of the air outlet end is in contact with the inner end surface of the inner annular boss 16 of the nozzle cover 10, and the outer wall of the air inlet end is provided with a second outer surface. An annular boss 13 , the second outer annular boss 13 fits with the annular groove 17 of the nozzle cover 10 .

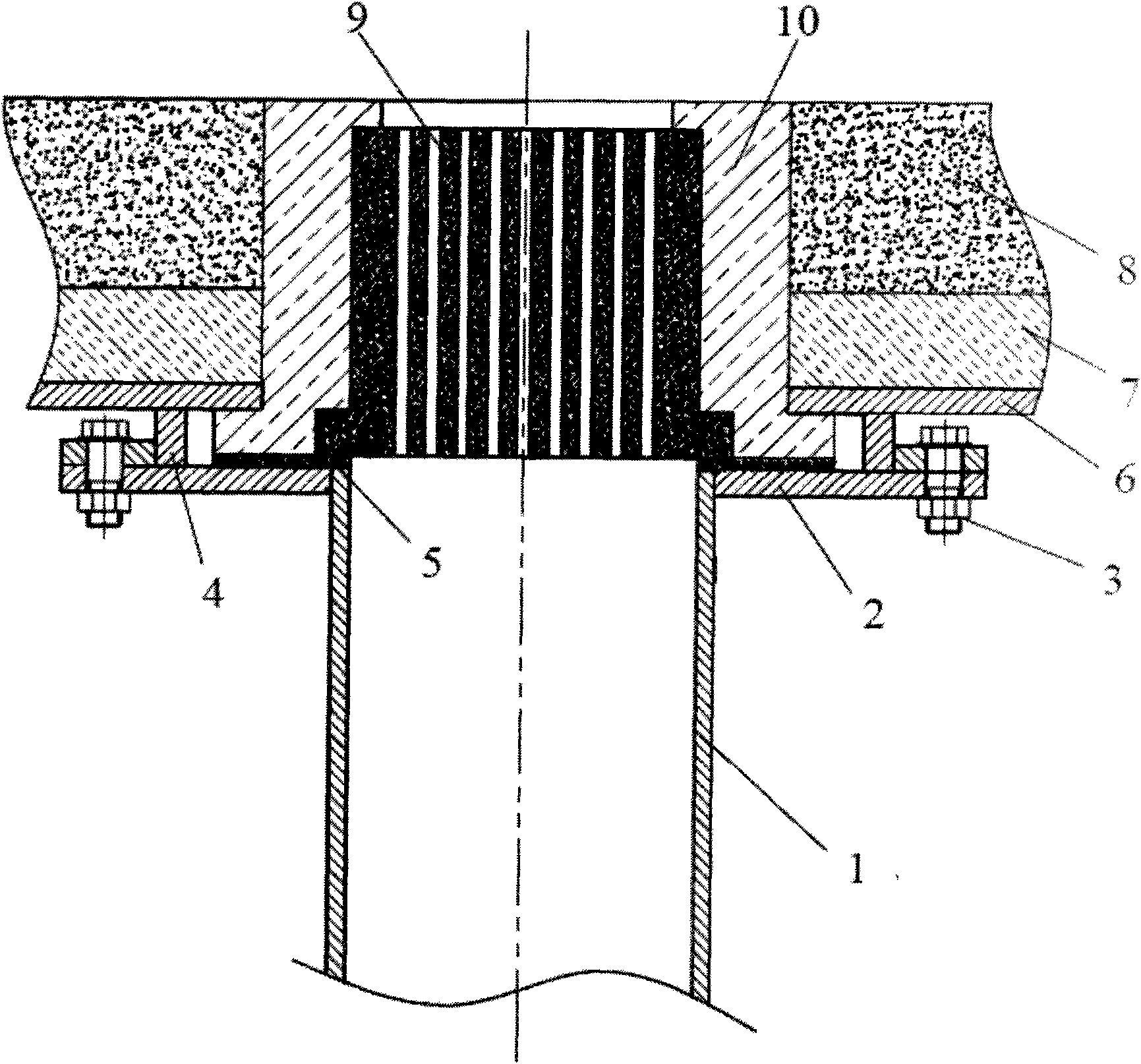

[0053] Such as figure 1 As shown, the rotary kiln includes: a kiln body and two or more air supply nozzles arranged on the kiln body, wherein at least one of the air supply nozzles is the above-mentioned combined air supply nozzle; The above-mentioned combined air supply nozzle is fixedly connected with the kiln ...

Embodiment 2

[0063] Such as figure 1 As shown, the kiln body of the rotary kiln includes: a kiln skin steel plate 6, a thermal insulation casting material layer 7 and a high temperature casting material layer 8, and the thermal insulation casting material layer 7 is between the kiln skin steel plate 6 and the high temperature casting material layer 8 . The kiln body is provided with two or more air supply nozzles, which can be divided into primary, secondary and tertiary air supply nozzles or more air supply nozzles according to the air supply requirements. In this embodiment, the secondary and tertiary air supply nozzles on the kiln body are replaced with combined air supply nozzles.

[0064] As shown in the figure, the nozzle cover 10 is a tubular structure embedded in the kiln wall of the kiln body, and the inner cavity 14 of the tubular structure matches the outer dimension of the nozzle core 9 . The nozzle cover 10 has an inner annular boss 16 on the inner wall of the outlet end, a...

Embodiment 3

[0068] This embodiment is based on embodiment 2, and the first flange described in embodiment 2 is changed into a structure composed of a disc-shaped flange and a cylindrical fixing ring fixedly connected to the surface of the disc-shaped flange, wherein the The fixing ring can be fixed on the disc flange by welding.

[0069] The preparation process of the rotary kiln described in embodiment 2 and embodiment 3 is as follows:

[0070] (1) Preparation of nozzle core

[0071] First of all, the refractory material is mixed into mud, which is formed by extrusion molding technology, and then air-dried in the natural environment. During the air-drying process, it is maintained for 2 to 3 times.

[0072] Then, put the cured molding material into a microwave oven for drying, raise the temperature to 120-150°C at a rate of 1.5-2.0°C per minute, keep it warm for 8-15 hours, and take it out to obtain the nozzle core body;

[0073] Finally, the nozzle core blank is cut and shaped, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com