Automobile air compressor aluminum cylinder block

An air compressor, cylinder block technology, applied in mechanical equipment, machines/engines, liquid variable volume machinery, etc. Good high temperature oxidation resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

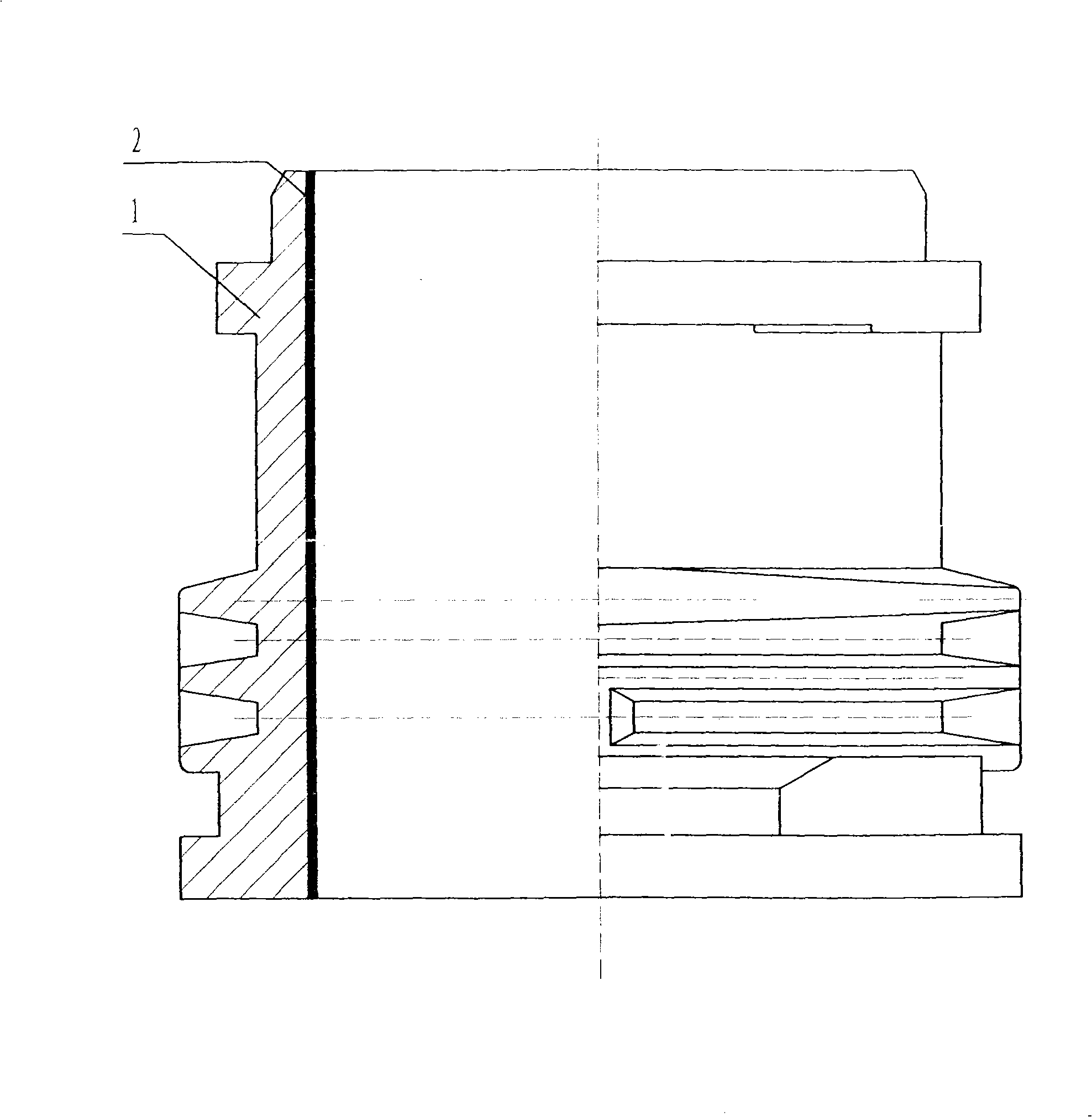

[0009] Referring to the accompanying drawings, an aluminum cylinder body of an automobile air compressor is provided with a composite nanomaterial layer 2 on the surface of the inner hole of the aluminum cylinder body 1 . The composition of the composite nanomaterial layer 2 is Ni and SiC with a particle size of 40-60nm, and is plated on the surface of the inner hole of the cylinder through a composite process of electroless plating and electroplating, and the thickness of the coating is 0.05-0.15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com