Insulating and decorating integrated composite precast concrete component and manufacturing method thereof

A prefabricated component and concrete technology, applied in building components, building structure, solid waste management, etc., can solve the problem of difficulty in forming a long-term stable, strong weather-resistant overall structure, easy delamination of thermal insulation layers and decorative layers, and complex construction processes. and other problems, to achieve the effect of not easy delamination and separation, reducing risk and construction difficulty, and strong weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

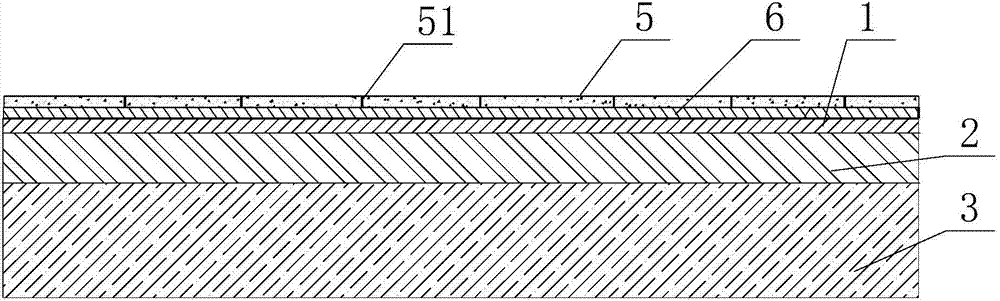

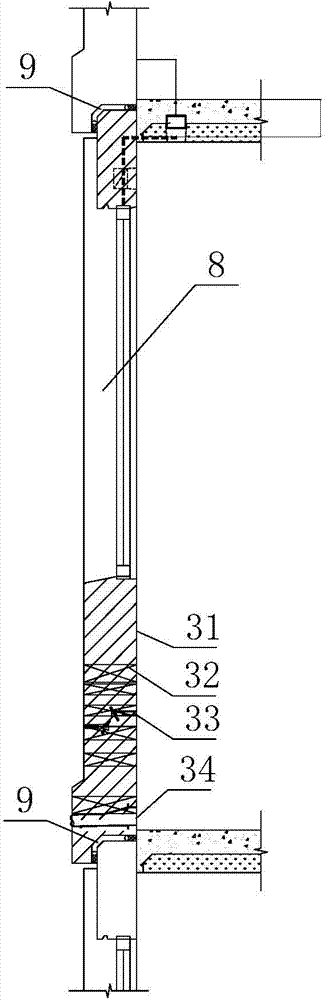

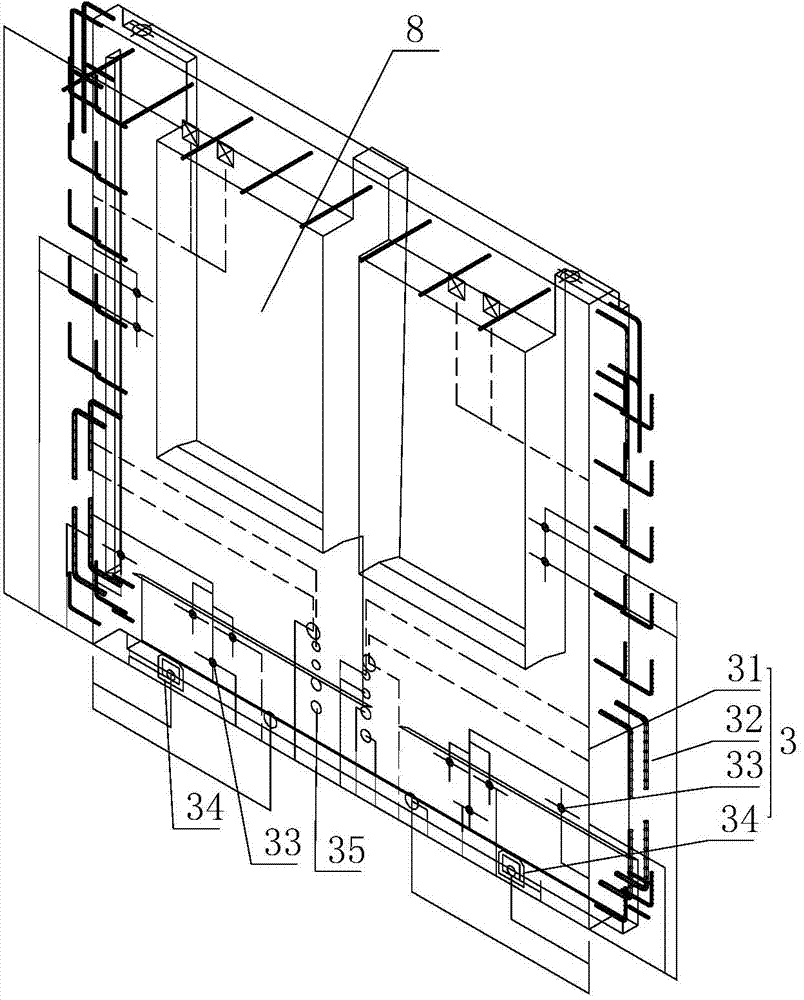

[0047] like Figure 1-3 As shown, an integrated composite concrete prefabricated component for thermal insulation and decoration includes decorative wall tiles 5 and a prefabricated part. It is a non-layered composite structure formed by sequentially consolidating the anti-cracking surface layer 1 made of anti-crack mortar mixture, the thermal insulation layer 2 made of thermal insulation mortar mixture and the concrete layer 3 made of concrete mortar mixture. The bonding mortar layer 6 is consolidated with the anti-cracking surface layer 1 , and the concrete layer 3 includes filled concrete 31 , a frame 32 and embedded parts, and the frame 32 extends into the thermal insulation layer 2 .

[0048] The outermost layer of the prefab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com