Ceramal material, and application thereof in ceramic-to-metal sealed electrode

A ceramic alloy and electrode technology, which is applied in the field of ceramic alloy electrodes, can solve the problems of complex-shaped electrode manufacturing and reduce production costs, and achieve the effects of low price, good chemical stability and stable market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

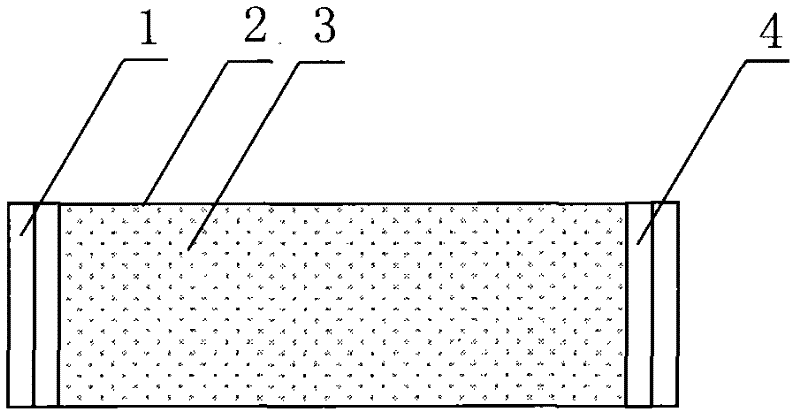

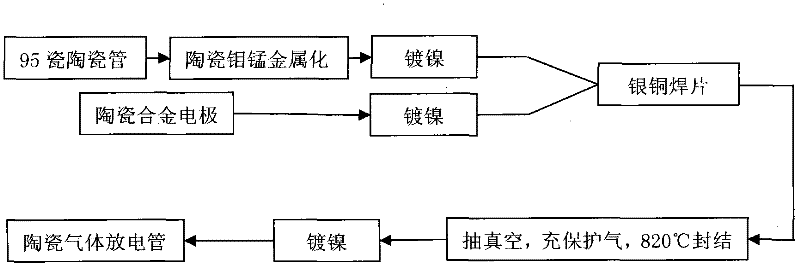

[0026] In the following, the present invention will be described by taking a ceramic-metal sealing electrode of a ceramic gas discharge tube.

[0027] Ceramic gas discharge tube is a kind of overvoltage protection device, which is widely used in overvoltage protection of network, communication, electric power, power supply and signal. It is a device with high air tightness requirements, so the expansion coefficient of ceramic and metal electrodes is required High matching. At present, the ceramic body of the ceramic gas discharge tube is made of 95 porcelain (95% aluminum oxide ceramics), and the thermal expansion coefficient is (5.5~7.5)×10 -6 / ℃, the metal electrode adopts 4J-34 iron-nickel alloy electrode, and the thermal expansion coefficient is (6.3~7.5)×10 -6 / °C, the thermal expansion coefficients of the two are close at 500 °C, and the thermal expansion coefficients at other temperatures are very different, which is a serious threat to the airtightness of ceramic gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com