Copper-nickel-silver brazing paste and preparation method thereof

A technology of silver brazing and copper-nickel-silver, which is applied in the field of copper-nickel-silver brazing paste and its preparation, can solve the problems of inconsistent thermal conductivity and expansion coefficient, accelerated creep aging of welded joints, and poor strength of brazed joints, etc. Achieve the effect of high brazing joint strength, solve the problem of brazing strength, and improve service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

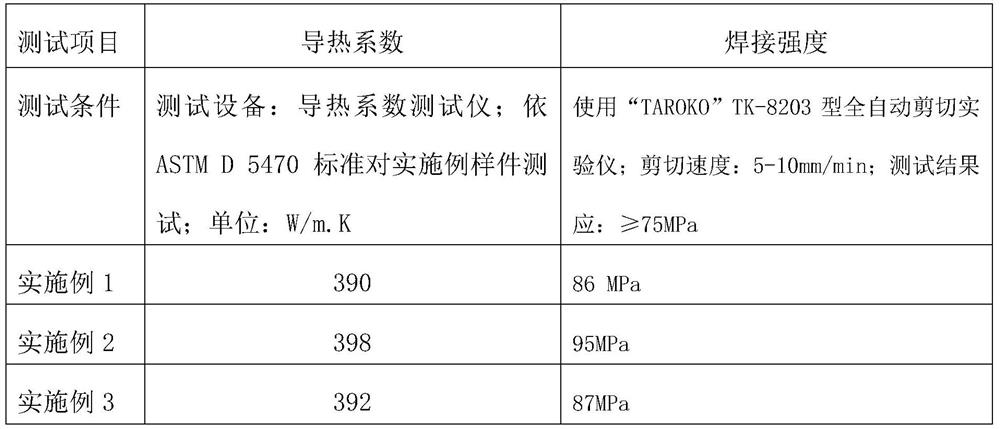

Examples

Embodiment 1

[0055] Step 1, the components of the second component brazed solder 1 white ore oil: 45kg, 2 polyethylene glycol: 42.5kg, 3 polyisobutylene: 2.8kg, 4 high-efficiency surfactant: 0.5kg, 5 phenolic Resin: 2.0kg, 6 Tween: 1.5kg After mixing to 90 ° C, after the solid material is all melted, the temperature drops to room temperature, then adding material 7 trimophosphate: 2.0 kg, 8 fluoroborate: 3.7 Kg, opening emulsification for about 30 minutes, making brazing aid cream;

[0056] Step 2, the first component metal alloy powder is mixed with the brazing additive paste obtained by the step 1, wherein the mass percentage of metal alloy powder is 88%, and the mass percentage of the brazing flux paste is 12. %; Then stirred by a star dispersion mixer for about 50 minutes, i.e., the copper nickel silver brazing slurry of the present invention.

Embodiment 2

[0058] Step 1, the components of the second component brake solder 1 white ore oil:

[0059] 42.0kg, 2 polyethylene glycol: 43.0kg, 3 polyisobutylene: 3.0kg, 4 high-efficiency surfactant: 1.0kg, 5 phenolic resin: 3.0kg, 6 Tween: 2.0kg After mixing, heating to 90 ° C, After all solid materials melt, the temperature is reduced to room temperature, then the material 7 tripolyphosphate: 2.5 kg, 8 fluoroborate: 3.5 kg, the emulsion is stirred for about 30 minutes, and the brazing adder paste is produced;

[0060] Step 2, the first component metal alloy powder is mixed with the brazing additive paste obtained by the step 1, wherein the mass percentage of the metal alloy powder is 87%, the mass percentage of the soldering flux paste is 13. %; Then stirred by a star dispersion mixer for about 50 minutes, i.e., the copper nickel silver brazing slurry of the present invention.

Embodiment 3

[0062] Step 1, the components of the second component brake solder 1 white ore oil:

[0063] 48.0kg, 2 polyethylene glycol: 40.5kg, 3 polyisobutylene: 2.5kg, 4 high-efficiency surfactant: 0.5kg, 5 phenolic resin: 2.0kg, 6 Tween: 1.5kg After mixing to 90 ° C, After all solid materials melt, the temperature is reduced to room temperature, then the material 7 tripolyphosphate is added: 2.0 kg, 8. Potassium borate: 3.0kg, the emulsion is stirred for about 30 minutes, and the brazing additive paste is produced;

[0064]Step 2, the first component metal alloy powder is mixed with the brazing additive paste obtained by the step 1, wherein the mass percentage of the metal alloy powder is 87%, the mass percentage of the soldering flux paste is 13. %; Then stirred by a star dispersion mixer for about 50 minutes, i.e., the copper nickel silver brazing slurry of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com