High-density underwater epoxy repair adhesive and preparation method and application thereof

A high-density, repairing glue technology, applied in the direction of epoxy resin glue, adhesives, non-polymer adhesive additives, etc., can solve the problems of epoxy glue ratio changes, water pollution, small molecules, etc., to achieve increased low shear The effect of cutting viscosity, ensuring the ratio and strength, and improving the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

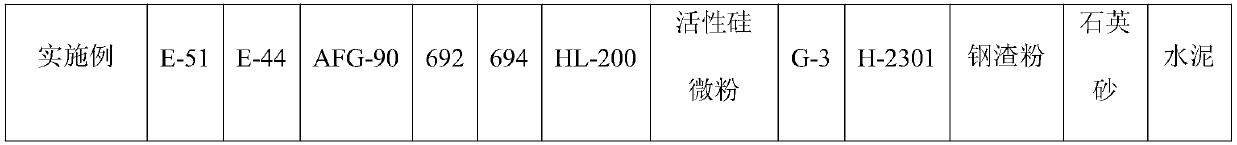

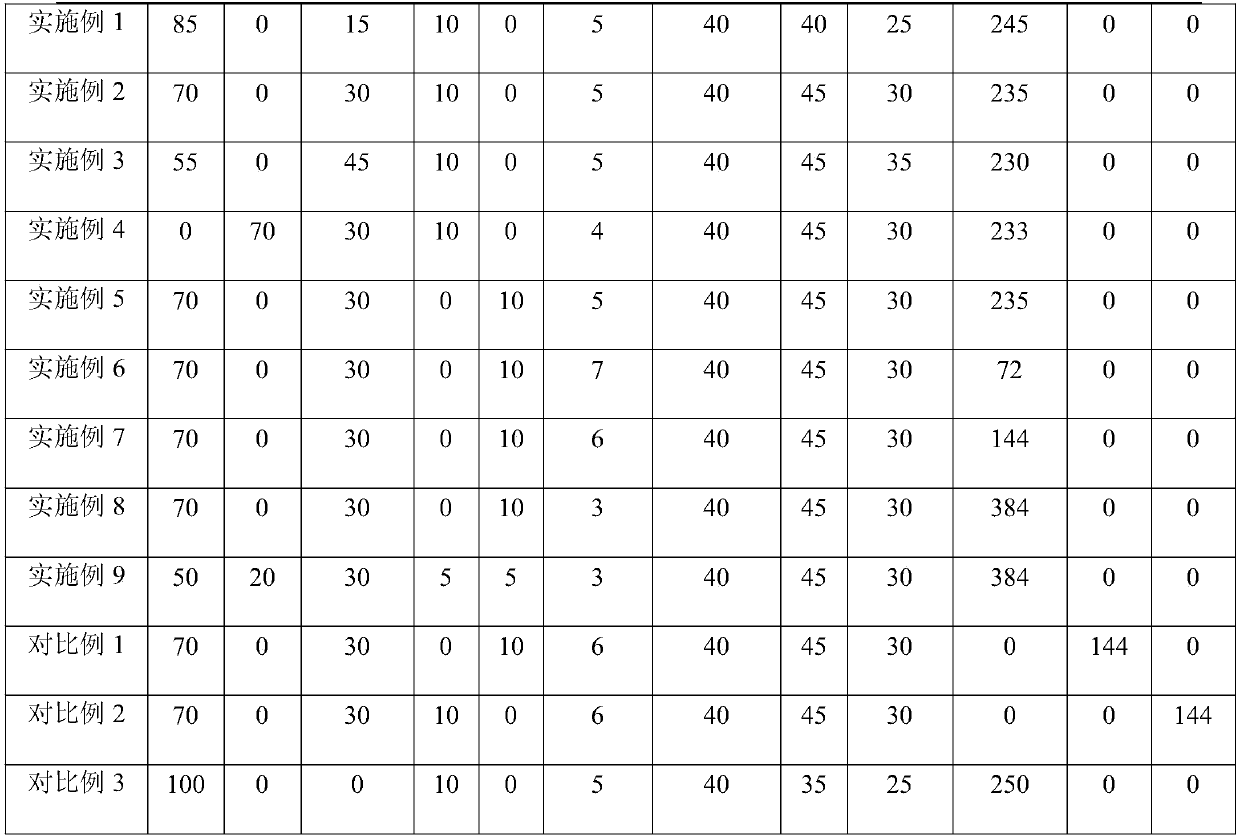

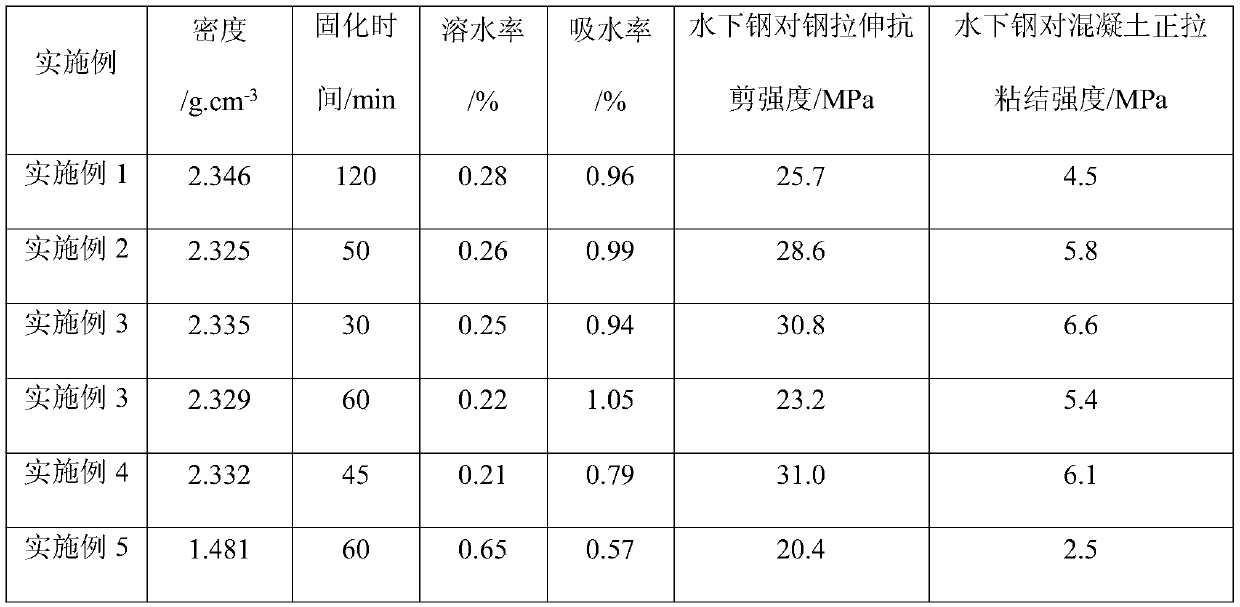

Embodiment 1

[0041] To prepare high-density underwater epoxy repair glue, see Table 1 for the dosage of each raw material. The preparation of component A: first weigh the specified mass of bisphenol A epoxy resin, low viscosity aminophenol-based trifunctional epoxy resin, active diluent Stir at 300r / min for 2min with a mixer; then reduce the speed to 120r / min, add the thixotropic agent while stirring, after all the thixotropic agent is added, increase the speed to 2000r / min, stir for 15min; then reduce the speed To 120r / min, add active silicon micropowder while stirring, and finally increase the speed to 300r / min, stir for 3min, and then obtain component A. Preparation of component B: Stir Mannich modified phenalkamine and modified alicyclic amine for 2 minutes at a speed of 300r / min, then reduce the speed to 180r / min, add steel slag powder while stirring, and finally increase the speed to 300r / min, continue to stir for 3min, and the B component is obtained. Finally, component A and compo...

Embodiment 2

[0046] For the preparation of high-density underwater epoxy repair glue, the dosage of each raw material is shown in Table 1, and the preparation method is the same as in Example 1.

Embodiment 3

[0048] For the preparation of high-density underwater epoxy repair glue, the dosage of each raw material is shown in Table 1, and the preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com