Imitation marble glaze heat-resistant porcelain formula and preparation method thereof

A technology of imitating marble and heat resistance, which is applied in the preparation of the formula of imitation marble glaze heat-resistant porcelain, and the formula field of imitating marble glaze heat-resistant porcelain, which can solve the problems affecting the decorative effect and aesthetics, the stability of glaze crack resistance, and the finished product. problems such as low rate, to achieve the effect of improving aesthetics, improving pass rate, and consistent expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

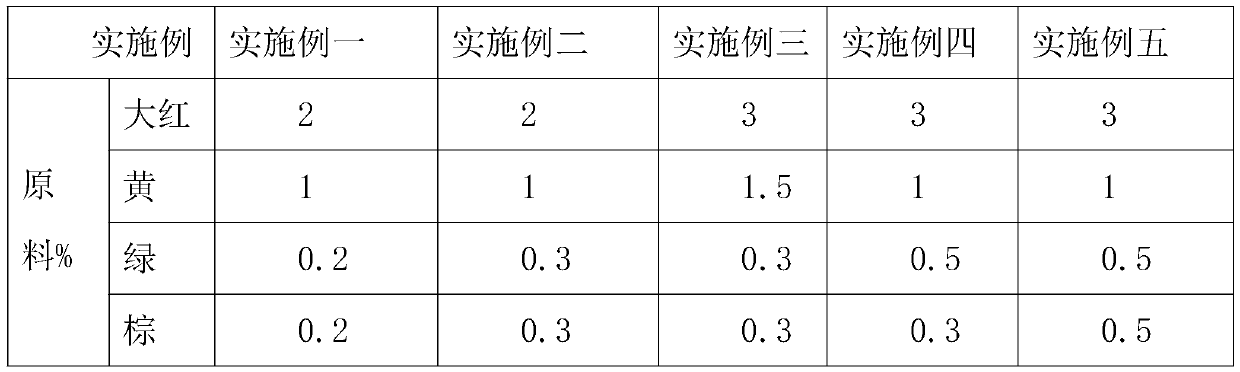

Embodiment 1

[0030] A formula of imitation marble glaze heat-resistant porcelain, its raw materials are as follows in terms of mass percentage: 96.6% of base material, 3.4% of additives, the base material is a basic white glaze, and the basic white glaze is spodumene, petalite and kaolin , the mixing ratio of spodumene, petalite and kaolin is 2:1:1, the additives are bright red material, yellow material, green material and brown material, and the bright red material, yellow material, green material The ratio with the brown material is as follows by mass percentage: 2% of the bright red material, 1% of the yellow material, 0.2% of the green material, and 0.2% of the brown material.

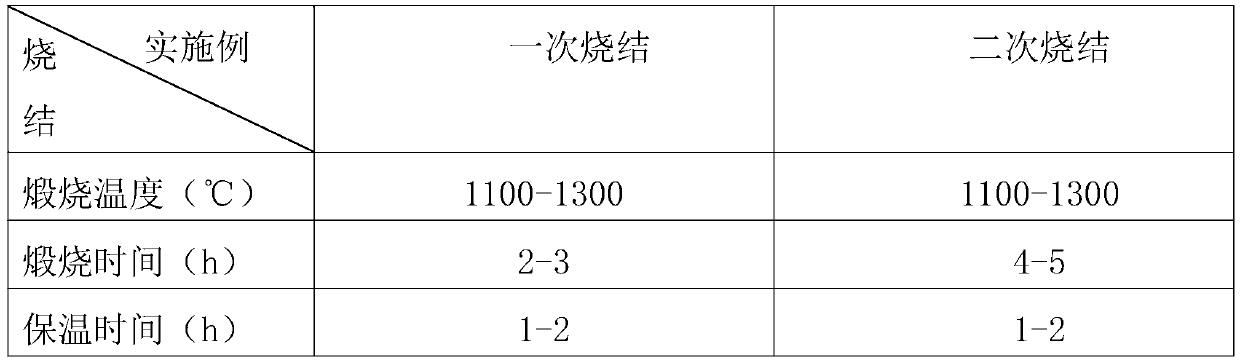

[0031] The present invention also provides a preparation method of imitation marble glaze heat-resistant porcelain formula, comprising the following steps:

[0032] S1: Weigh the color base material and additives by mass percentage for later use;

[0033] S2: Preparation of bottom glaze, details are as follows...

Embodiment 2

[0047] A formula of imitation marble glaze heat-resistant porcelain, its raw materials are as follows in terms of mass percentage: 96.4% of base material, 3.6% of additives, the base material is a basic white glaze, and the basic white glaze is spodumene, petalite and kaolin , the mixing ratio of spodumene, petalite and kaolin is 2:1:1, the additives are bright red material, yellow material, green material and brown material, and the bright red material, yellow material, green material The ratio with the brown material is as follows by mass percentage: 2% of the bright red material, 1% of the yellow material, 0.3% of the green material, and 0.3% of the brown material.

[0048] The present invention also provides a preparation method of imitation marble glaze heat-resistant porcelain formula, comprising the following steps:

[0049] S1: Weigh the color base material and additives by mass percentage for later use;

[0050] S2: Preparation of bottom glaze, details are as follows...

Embodiment 3

[0064] A formula for imitating marble glaze heat-resistant porcelain, the raw materials of which are as follows in terms of mass percentage: 94.5-96.6% of base material, 5.1% of additives, the base material is a basic white glaze, and the base white glaze is spodumene, lithium permeable long Stone and kaolin, the mixing ratio of spodumene, petalite and kaolin is 2:1:1, the additives are bright red material, yellow material, green material and brown material, and the bright red material, yellow material, The ratio of green material and brown material is as follows by mass percentage: bright red material 2%, yellow material 1.5%, green material 0.3%, brown material 0.3%.

[0065] The present invention also provides a preparation method of imitation marble glaze heat-resistant porcelain formula, comprising the following steps:

[0066] S1: Weigh the color base material and additives by mass percentage for later use;

[0067] S2: Preparation of bottom glaze, details are as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com