Method for plating gold on surface of titanium alloy

A surface gold plating, titanium alloy technology, applied in the field of titanium alloy surface gold plating, can solve the problem of poor bonding force of the film base and achieve the effect of improving the bonding force of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

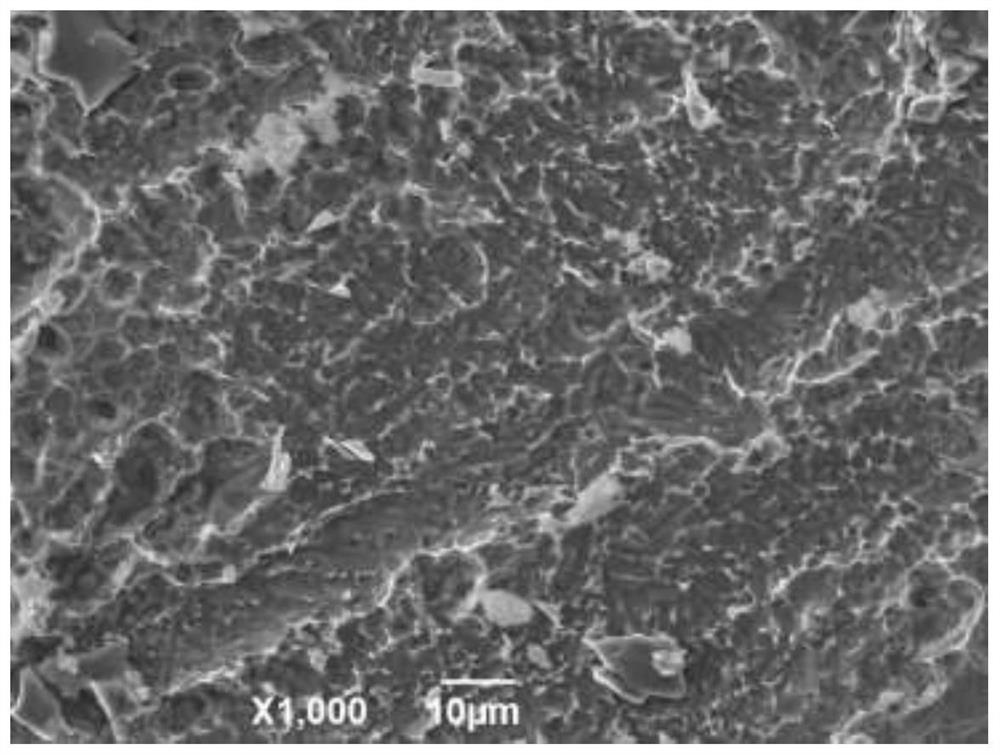

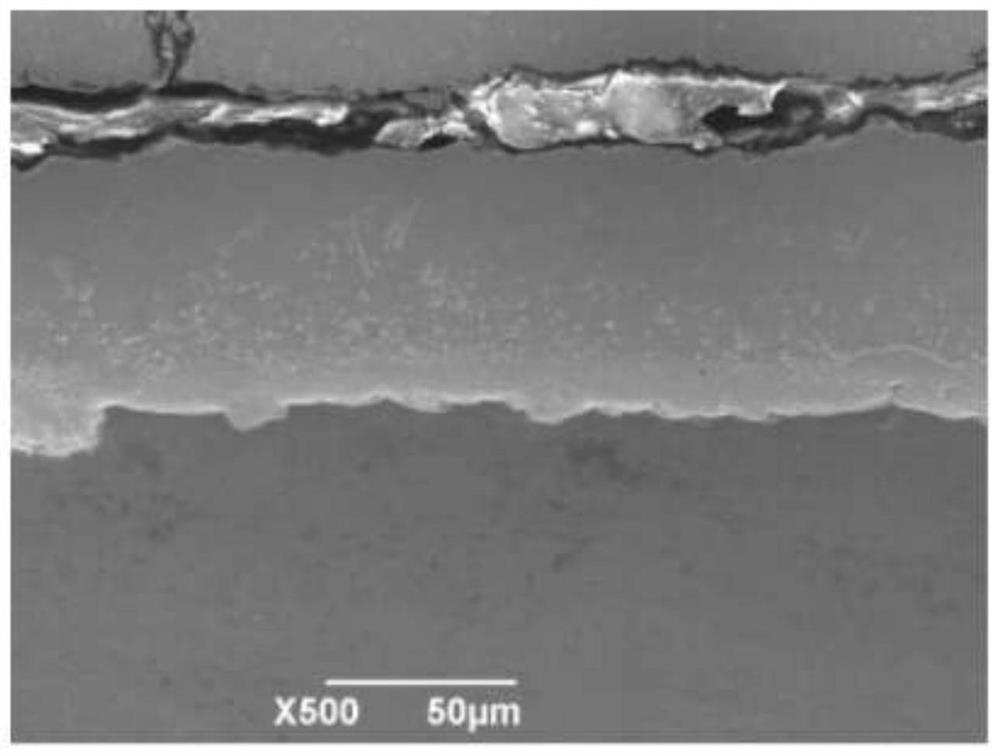

[0020] Please refer to figure 1 , figure 2 ,in, figure 1 A schematic diagram of the surface morphology of the titanium alloy after acid etching of the method for gold plating on the surface of the titanium alloy provided by the present invention; figure 2 It is a schematic cross-sectional view of a nickel-plated gold layer on a titanium alloy after heat treatment in the method for gold-plated titanium alloy surface provided by the present invention. The method for gold plating on the surface of titanium alloy comprises the following steps:

[0021] First, put a 30×50×2mm titanium alloy plate made of Ti6Al4V into a solution with a mass concentration of 15% sodium hydroxide + 20% sodium bicarbonate for alkaline cleaning at 60°C for 8 minutes, rinse and soak in pure water for later use , and then put the degreased titanium plate into the oxalic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com