Backlight assembly

A technology for backlight components and light sources, applied in optical elements, light guides, optics, etc., can solve the problems of uneven heating of aluminum substrates, decreased heat dissipation effect, and impact on the life of light-emitting diode components, and achieve good optical performance, uniform deformation, and good heat dissipation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

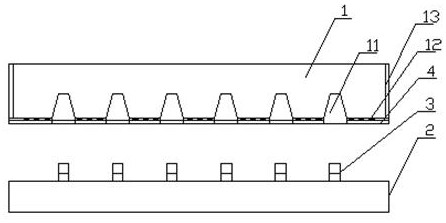

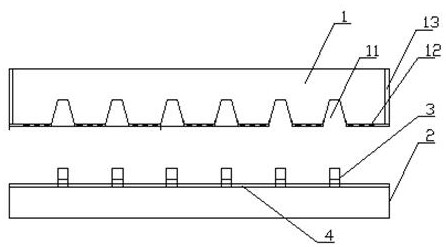

[0028] Such as Figure 1-3 The shown backlight assembly includes a light guide plate 1, a substrate 2, and several light sources 3; the light source can be an LED chip or a lamp bead. The light board includes the board body. The board body can be made of high-temperature resistant PS plastic board or PC plastic board or miniLED packaging glue or high-temperature resistant MS plastic board. You can also choose a glass board with better light transmittance; one side of the board body is the entrance The light surface and the other side are the light-emitting surface, and the light-incoming surface is provided with a number of grooves 11. The molding process of the grooves depends on the material of the light guide plate body; 0.1-1.0mm gap, the distribution method is distributed according to the distribution method of the light source on the substrate; the peripheral side of the board is provided with a first reflective layer, and the rest of the groove on the light incident sur...

Embodiment 2

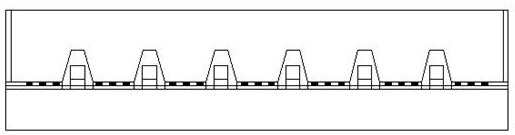

[0029] Embodiment 2: Same as other technical features of Embodiment 1, in order to further enhance the uniformity of light output, a second reflective layer 111 can be provided on the bottom wall of the groove, especially when using LED chips or lamp beads that emit light from the top. This setting is more necessary; combined with Figure 4 As shown, the second reflective layer is not limited to being flat, and may also be curved. The second reflective layer is a reflective sheet or a specular ink layer.

[0030] On the one hand, the function of the heat-conducting reflective layer is to reflect the light emitted by the light source toward the substrate to avoid light leakage; on the other hand, it is to efficiently and uniformly transmit the heat generated by the light source to the substrate to avoid excessive working temperature of the backlight assembly. Existing heat-conducting reflective layers usually use PET-based heat-conducting reflective sheets containing heat-cond...

Embodiment 3

[0031] Embodiment 3: The research and application direction of the mirror ink in the prior art lies in how to improve its reflectivity, and we are surprised to find that on the basis of Embodiment 1, the side of the printed conductive circuit on the substrate, or the entrance of the light guide plate The high-temperature-resistant mirror ink layer formed by glossy screen printing or spraying high-temperature-resistant mirror ink not only has a reflectivity close to 100%, but also can quickly and evenly conduct heat to the substrate, so that the substrate can fully dissipate heat and avoid overheating of the backlight assembly. The high temperature-resistant mirror ink and its preparation method can be, but not limited to, the technical scheme disclosed in the invention patent with the patent application number CN202110687449.X; The choice of points should give consideration to reflective performance and thermal conductivity as much as possible.

[0032]In the above embodiments...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com