Overturning Test System of Catenary Overhaul Vehicle

A technology of a test system and an operating vehicle, which is applied in the field of overturning test systems for overhauling overhauling overhaul vehicles, can solve problems such as the center of gravity of the vehicle is biased to one side, prone to overturning, and economic losses, so as to avoid overturning accidents, improve safety, and avoid The effect of economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

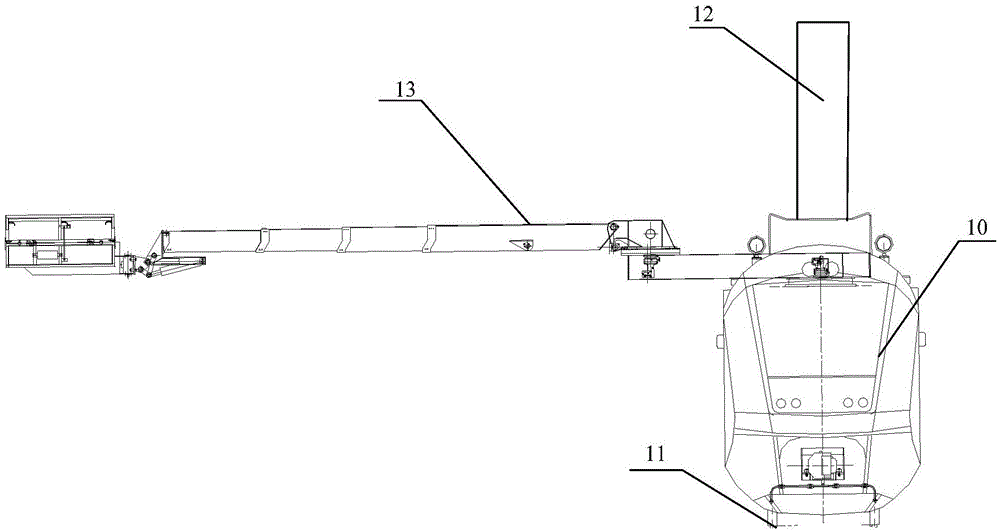

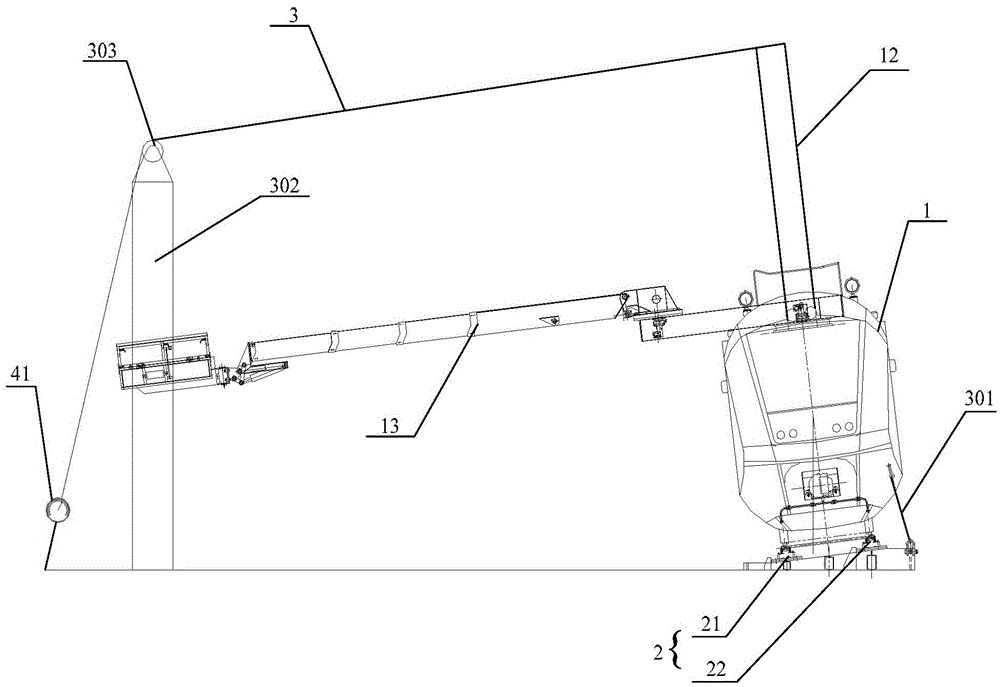

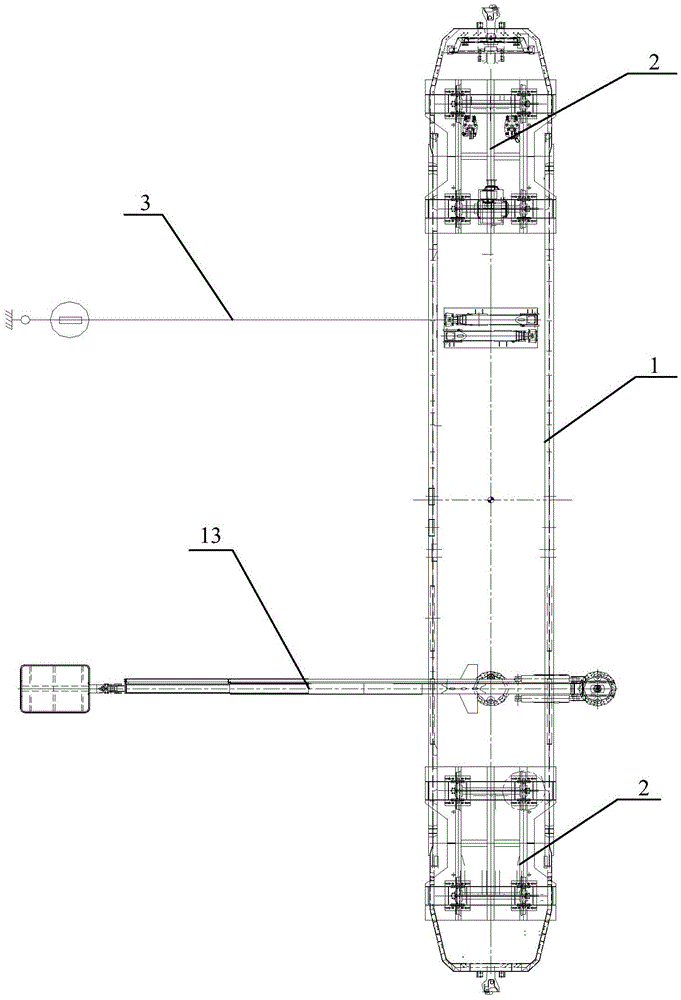

[0016] figure 2 It is a schematic diagram of the use state of the embodiment of the overturning test system of the catenary maintenance work vehicle of the present invention; image 3 for figure 2 top view of ; Figure 4 for figure 2 Schematic diagram of the structure of the middle rail row. Please refer to Figure 2-4 , this embodiment provides a catenary maintenance vehicle overturning test system, including: at least one set of rail rows 2 , connecting ropes 3 , a first sensor 41 and at least two second sensors 42 . At least one set of rail rows 2 is used to support the catenary maintenance vehicle 1 to be tested; each rail row 2 includes a first rail 21 and a second rail 22 that are parallel to each other, and the second rail 22 is higher than the first rail; connecting ropes One end of 3 is used to be fixedly connected to the support arm 12 of the catenary maintenance vehicle 1, and the other end of the connecting rope 3 is fixedly connected to the ground or the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com