Hot melt adhesives for multilayer structure enclosures

A composite adhesive and tackifier technology, applied in the bonding field of kraft paper and composite film, can solve problems such as generation and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

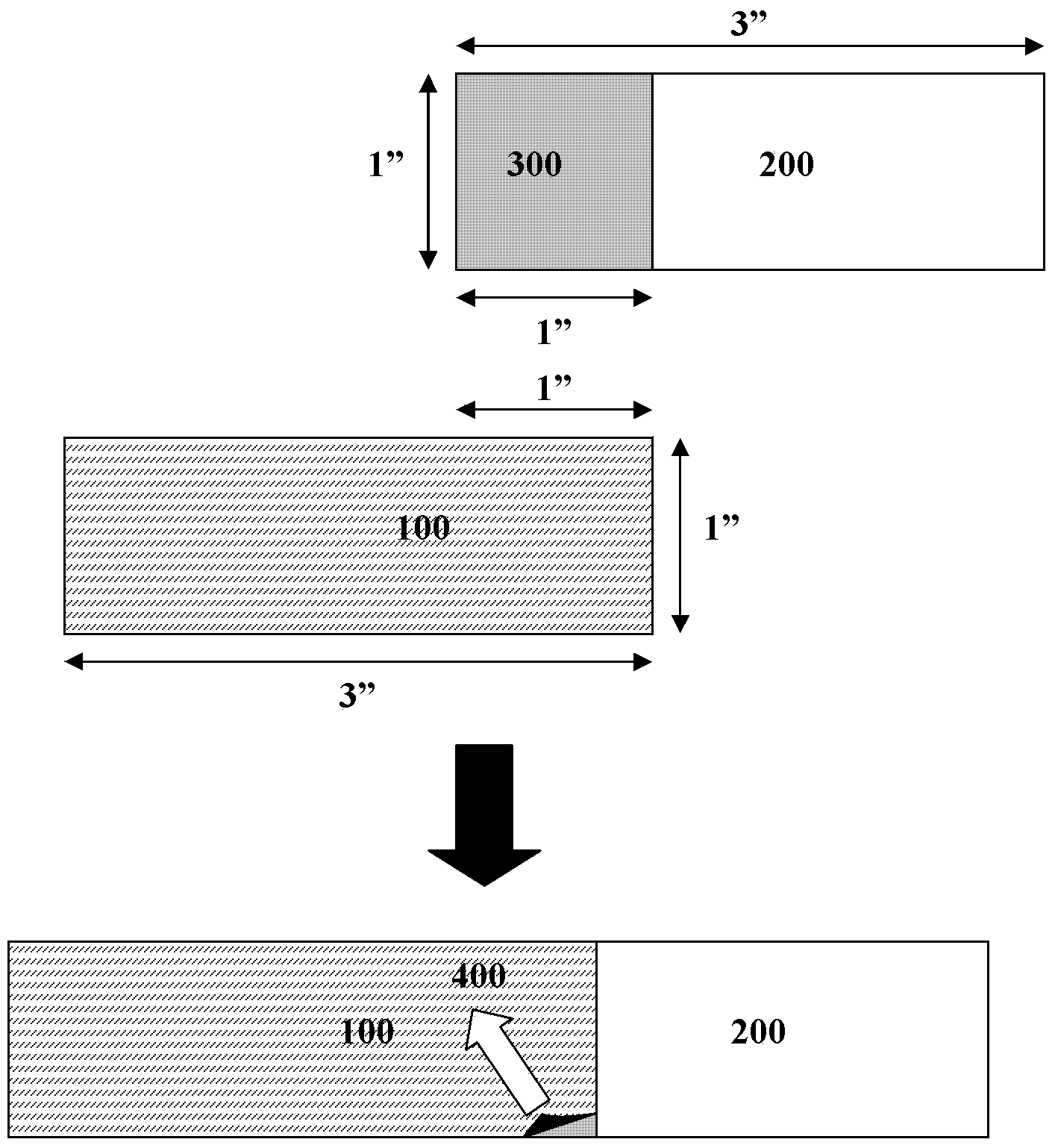

[0059] In another embodiment, the method of sealing the pinch bottom bag comprises:

[0060] (i) applying the above adhesive to both open end flaps of a preformed tubular, wherein said preformed tubular is a laminate having multiple layers consisting of a composite film, kraft paper and optionally Made of plastic lining;

[0061] (ii) folding a flap of a sufficient amount to seal one end, thereby causing the adhesive to seal the end of the tube;

[0062] (iii) cooling the remaining adhesive to room temperature;

[0063] (iv) heating to reactivate the remaining adhesive; and

[0064] (v) Folding a sufficient amount of the remaining opening flaps to seal the remaining ends, thereby allowing the reactivated adhesive to seal the remaining ends.

[0065] In another configuration, by rolling or folding the sides of the bag inwardly a sufficient amount and folding the flap, and then sealing the flap with the adhesive and / or reactivated adhesive, the This inner seals the tube.

...

Embodiment

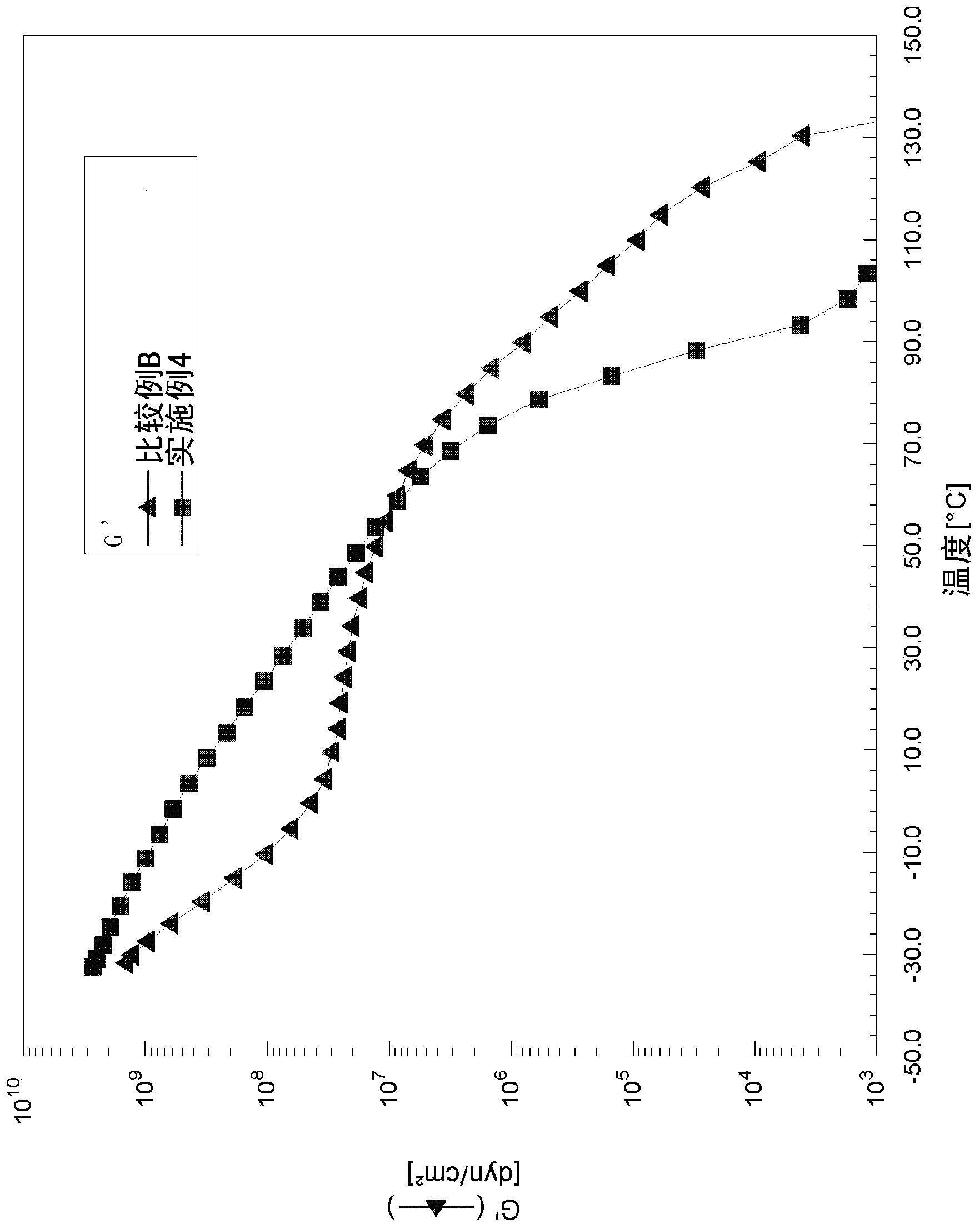

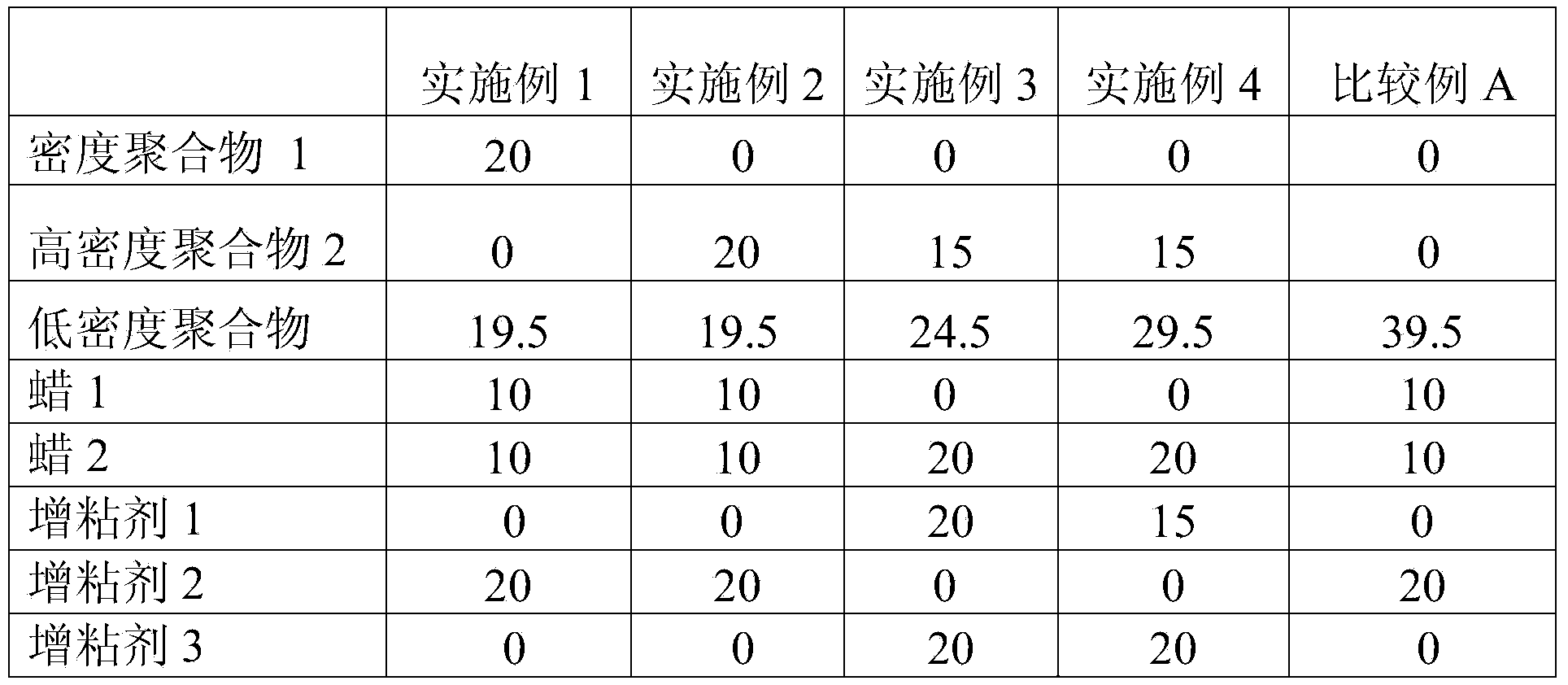

[0073] The samples listed in Table 1 were prepared using techniques known in the art. The components of each adhesive sample are listed in this table. An exemplary procedure includes placing about half of the total amount of tackifier into a jacketed mixing pot with a rotor and raising the temperature to a range of about 100°C to 200°C. When the tackifier is molten, start stirring and add the remaining ingredients until a homogeneous mass is obtained.

[0074] High Density Polymer 1 is a metallocene catalyzed polyolefin with 0.885 g / cm measured according to ASTM D792 3 density of.

[0075] High Density Polymer 2 is a metallocene catalyzed polyolefin with 0.902 g / cm measured according to ASTM D792 3 density of.

[0076] The low density polymer is a metallocene catalyzed polyolefin having 0.870 g / cm measured according to ASTM D792 3 density of.

[0077] Wax 1 is a polyethylene wax with a Brookfield viscosity of <50 cps at 140°C.

[0078] Wax 2 is a polyethylene wax grafte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com