Preparation method of ZIFs/LDHs composite material

A technology of composite materials and mixed solutions, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

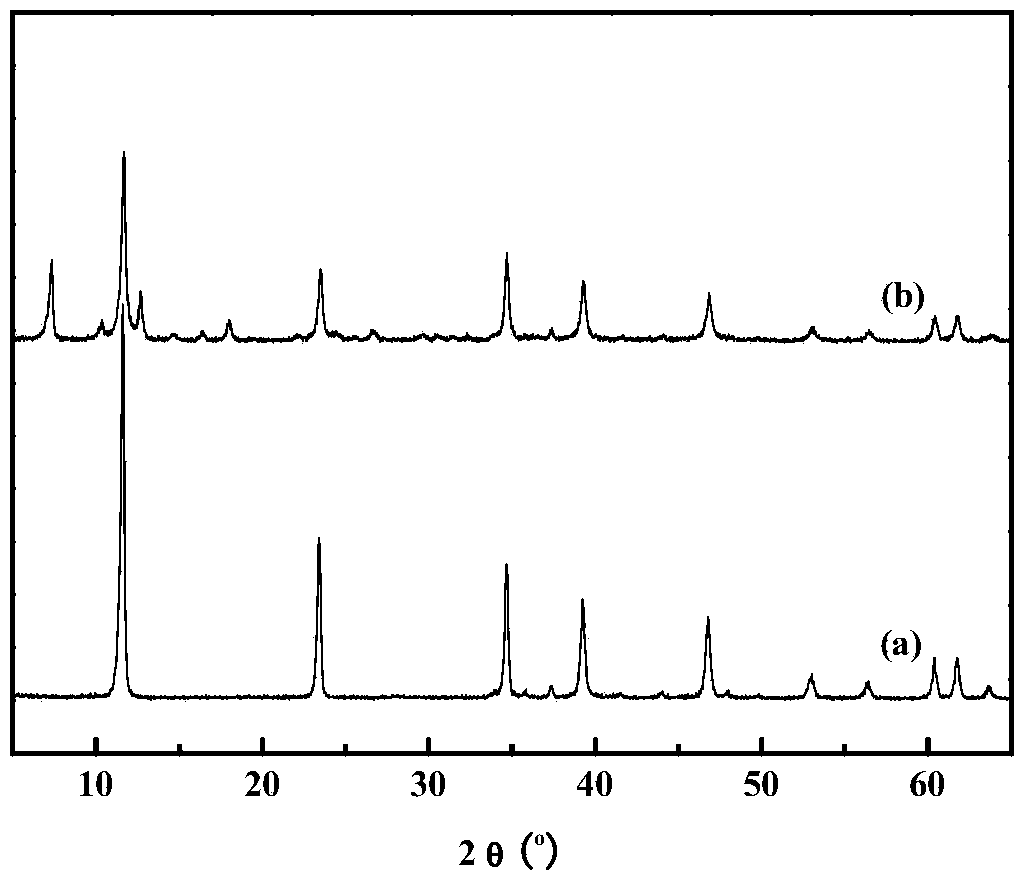

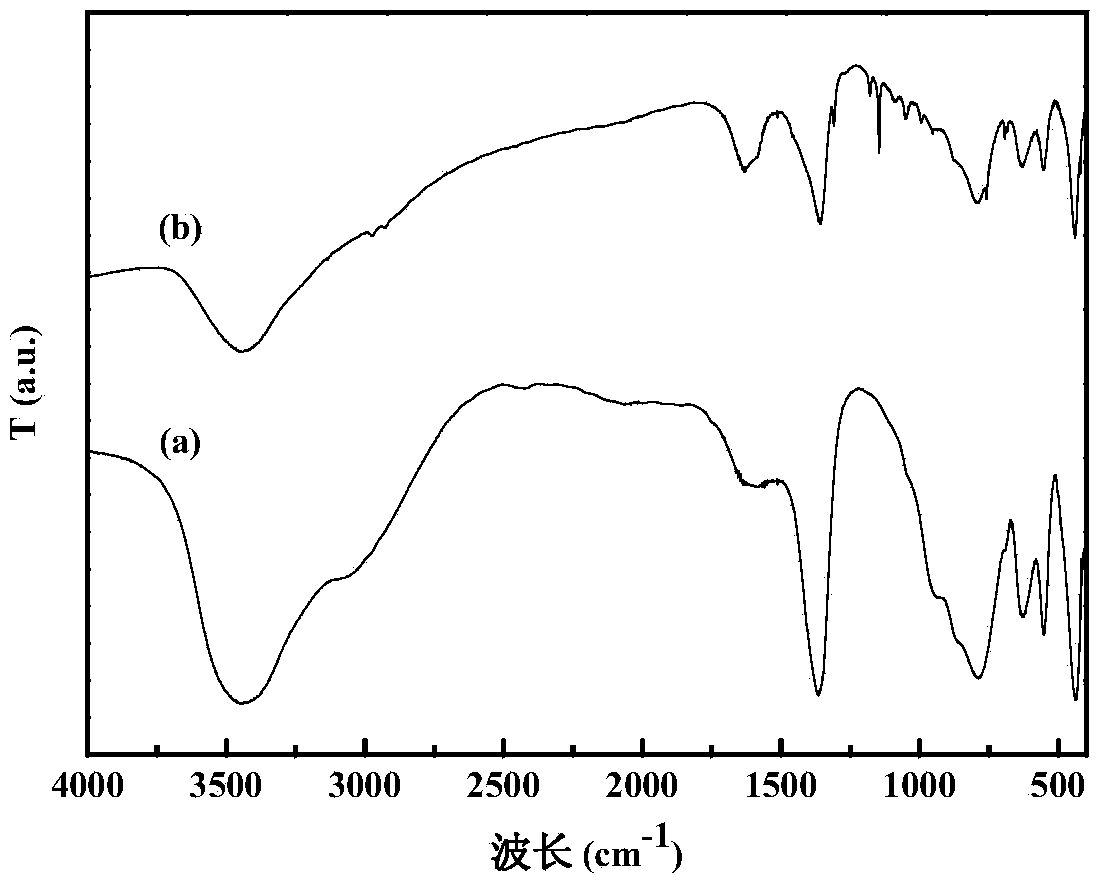

Image

Examples

Embodiment approach

[0011] Realize the embodiment of the present invention as follows:

Embodiment approach 1

[0012] Implementation mode 1: 60 mL containing 2 mmol Zn(NO 3 ) 2 ·6H 2 O, 4 mmol Mg(NO 3 ) 2 ·6H 2 O and 1.5 mmol Al(NO 3 ) 3 9H 2 The mixed solution of O and 2.0 mol / L NaOH solution were simultaneously dropped into 50 mL of 0.14 mol / L NaOH solution 2 CO 3 solution, the pH value was kept constant at 11 by adjusting the drop rate of NaOH solution, and then the prepared white emulsion was loaded into a 100 mL stainless steel reactor equipped with a polytetrafluoroethylene liner, and the o C / min is heated up to 140 ° C, crystallized for 2 hours, and the obtained sample is filtered and washed to neutrality, 80 o C dried for 8 hours to obtain ZnMgAl-LDH samples.

Embodiment approach 2

[0013] Implementation mode 2: 60 mL containing 2 mmol Zn(NO 3 ) 2 ·6H2 O, 0.5 mmol Ni(NO 3 ) 2 ·6H 2 O and 5 mmol Al(NO 3 ) 3 9H 2 The mixed solution of O and 2.0 mol / L NaOH solution were simultaneously dropped into 50 mL of 0.14 mol / L NaOH solution 2 CO 3 solution, the pH value was kept constant at 8 by adjusting the drop rate of NaOH solution, and then the prepared white emulsion was loaded into a 100 mL stainless steel reactor equipped with a polytetrafluoroethylene liner, and the o C / min is heated up to 180 ° C, crystallized for 20 hours, the resulting sample is filtered, washed to neutral, 80 o C dried for 8 hours to obtain ZnNiAl-LDH samples.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap