Round sieve machine

A sieve machine and circular sieve technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of downtime and low work efficiency, and achieve the effect of eliminating the hidden danger of bearing wear and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

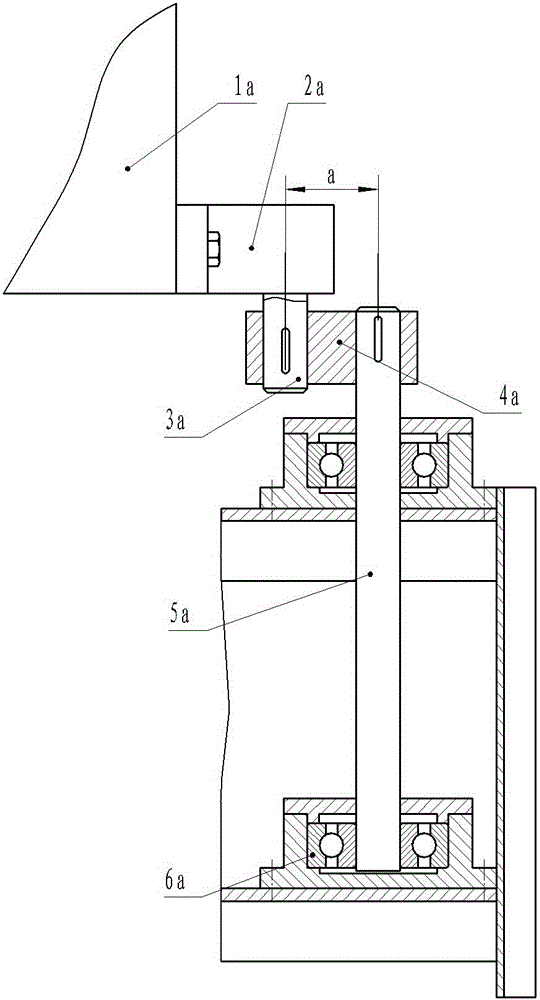

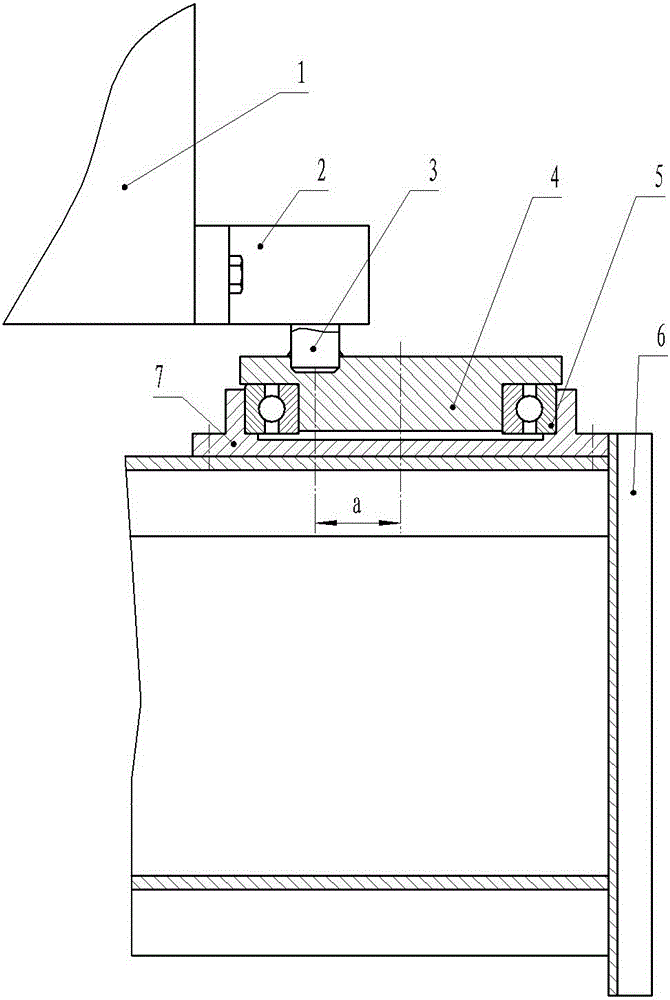

[0010] Such as figure 1 Shown is the circular screen machine of prior art, and this circular screen machine comprises the circular screen 1a that is installed on the frame through active eccentric device and driven eccentric device respectively, and active eccentric device is connected with power machine; The bearing 6a is installed on the rotating shaft 5a on the frame, the upper part of the rotating shaft 5a is equipped with an eccentric block 4a, and the eccentric block 4a is equipped with an eccentric shaft 3a which is offset from the rotating shaft 5a, and the eccentric shaft 3a is mounted on the eccentric shaft through the bearing. On the seat 2a, the eccentric seat 2a is fixed on the lower part of the circular screen 1a by bolts. When the eccentric shaft 3a of this structure rotates around the rotating shaft 5a with the circular screen 1a, since...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com