Horizontal multi-arc coating chamber

A coating chamber, horizontal technology, applied in the field of horizontal multi-arc coating chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

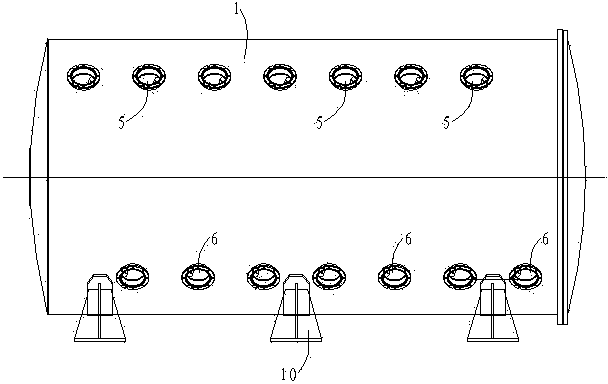

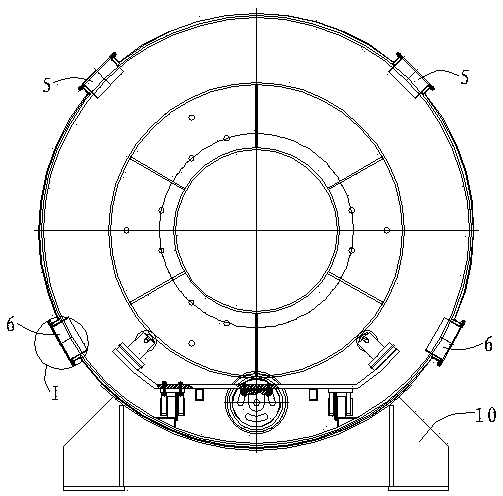

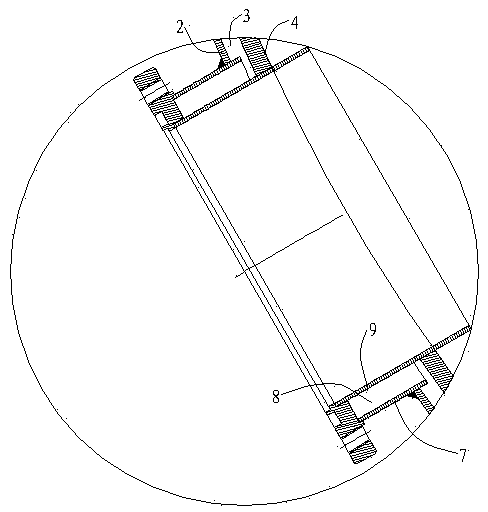

[0012] see figure 1 - image 3 , a horizontal multi-arc coating chamber of the present invention has a coating chamber tank body 1, the coating chamber tank body 1 has an outer wall 2, an intermediate cooling jacket layer 3 and an inner wall 4, and the upper and lower walls of the coating chamber tank body 1 are evenly distributed Arc source mounting holes 5 and 6 are installed, and the bottom of the coating chamber tank body 1 has a mounting bracket 10. The arc source mounting holes 5 and 6 include an installation outer wall 7 connected to the outer wall 2 of the coating chamber tank body 1, and an installation outer wall 7 connected to the coating chamber tank body 1. The installation inner wall 9 connected to the inner wall 4 of the tank body 1 and the installation jacket layer 8 communicated with the intermediate cooling jacket layer 3 of the tank body 1 of the coating chamber, the installation inner wall 9 protrudes from the inner wall 4 of the tank body 1 of the coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com