A roof insulation method

A floor and top surface technology, applied in the direction of roof insulation materials, building roofs, roof coverings, etc., can solve the problems of poor air quality, easy peeling off of heat insulation coatings, and unpleasant odors, etc., to prevent indoor The temperature rises too high, the heat insulation effect is obvious, the laying is convenient and the effect is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

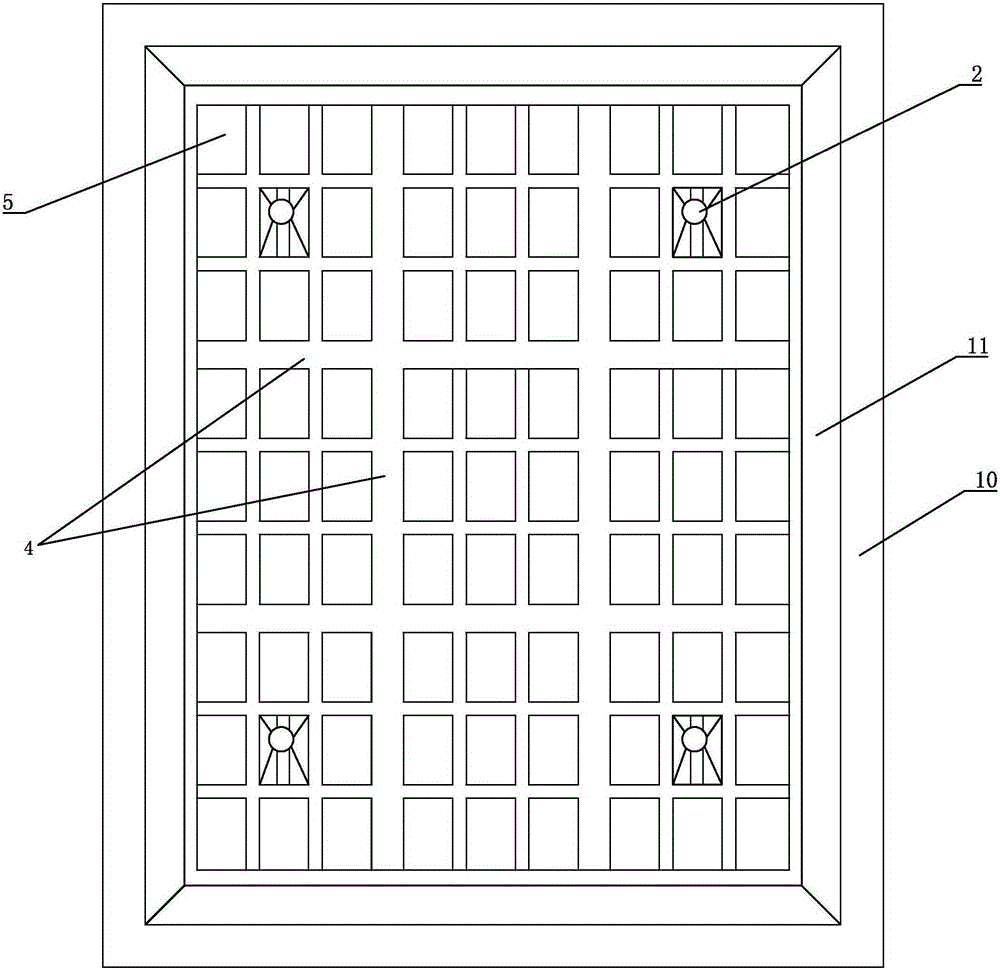

[0027] figure 1 Show the plan view of laying white tiles 5 on the roof of the present invention, the roof is provided with enclosure wall 10 and water slope 11, after the waterproof layer 3 of the roof is divided into a plurality of adjacent cells, in the area surrounded by the cells White tiles 5 are laid, and the white tiles 5 are located in the area surrounded by the cells. The gap between the white tiles 5 and the water slope 11 is filled with white cement, and expansion joints 4 are reserved between adjacent cells. The seam 4 is filled with white glass glue, and the gap between the white tiles 5 in the cell is filled with white cement. When laying white ceramic tile 5 at drainage pipe 2 places, white ceramic tile 5 can be cut into fritters earlier, and then spliced together again.

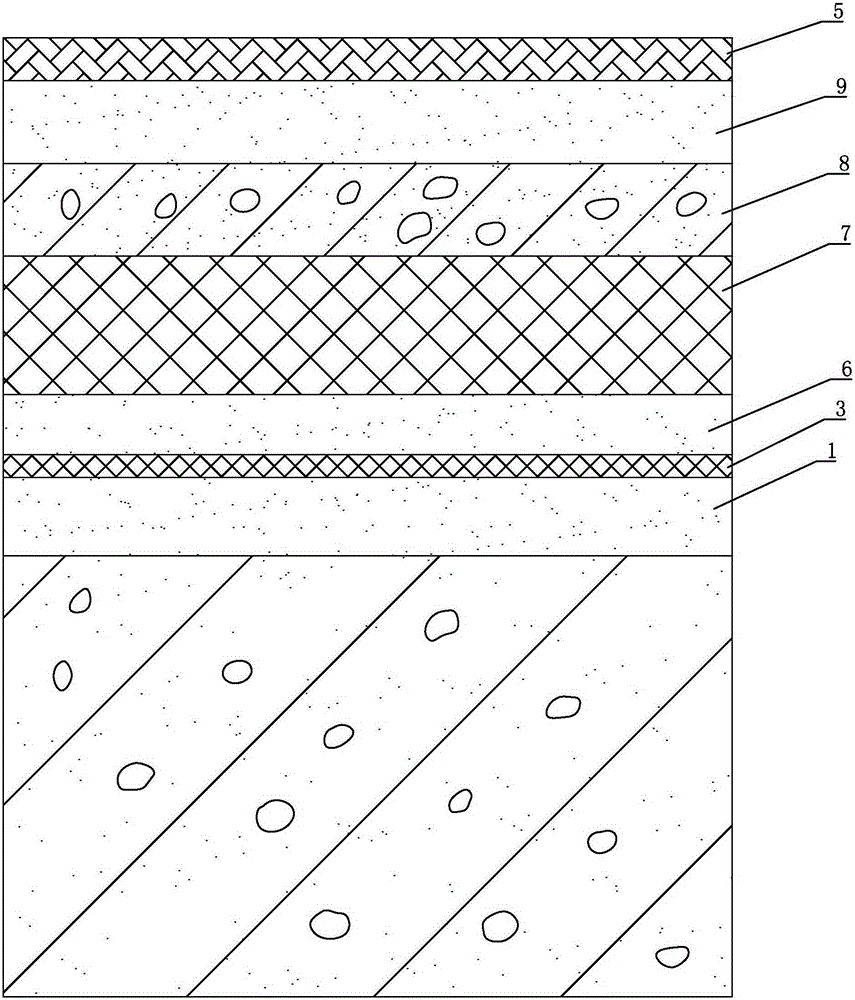

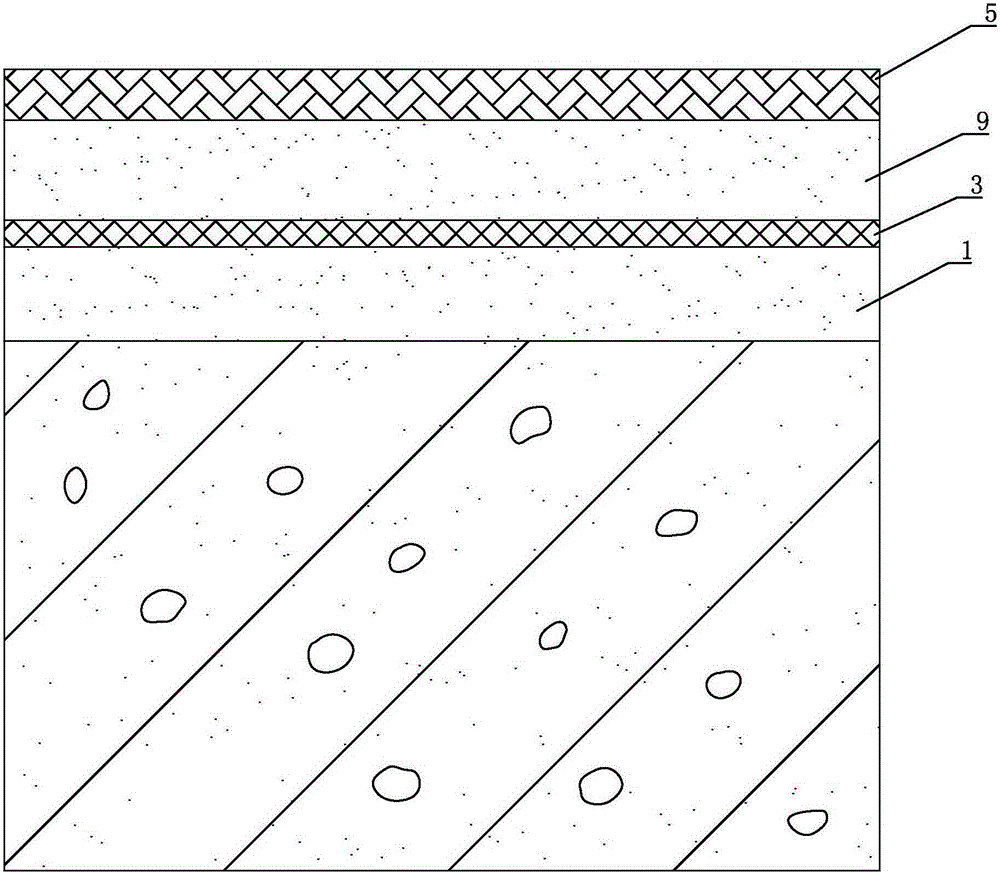

[0028] figure 2 The first embodiment of the present invention is shown. When heating facilities are installed in the building, regardless of the size of the floor area of the roof, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com