Sucker with sealing element

A technology of sealing parts and sealing discs, which is applied to suction cups, connecting components, mechanical equipment, etc., can solve the problems of insufficient suction force of suction cups, insufficient friction force, air leakage of vacuum chamber, etc., to ensure the adsorption force, prevent shrinkage, Guarantee the effect of vacuum adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with accompanying drawing:

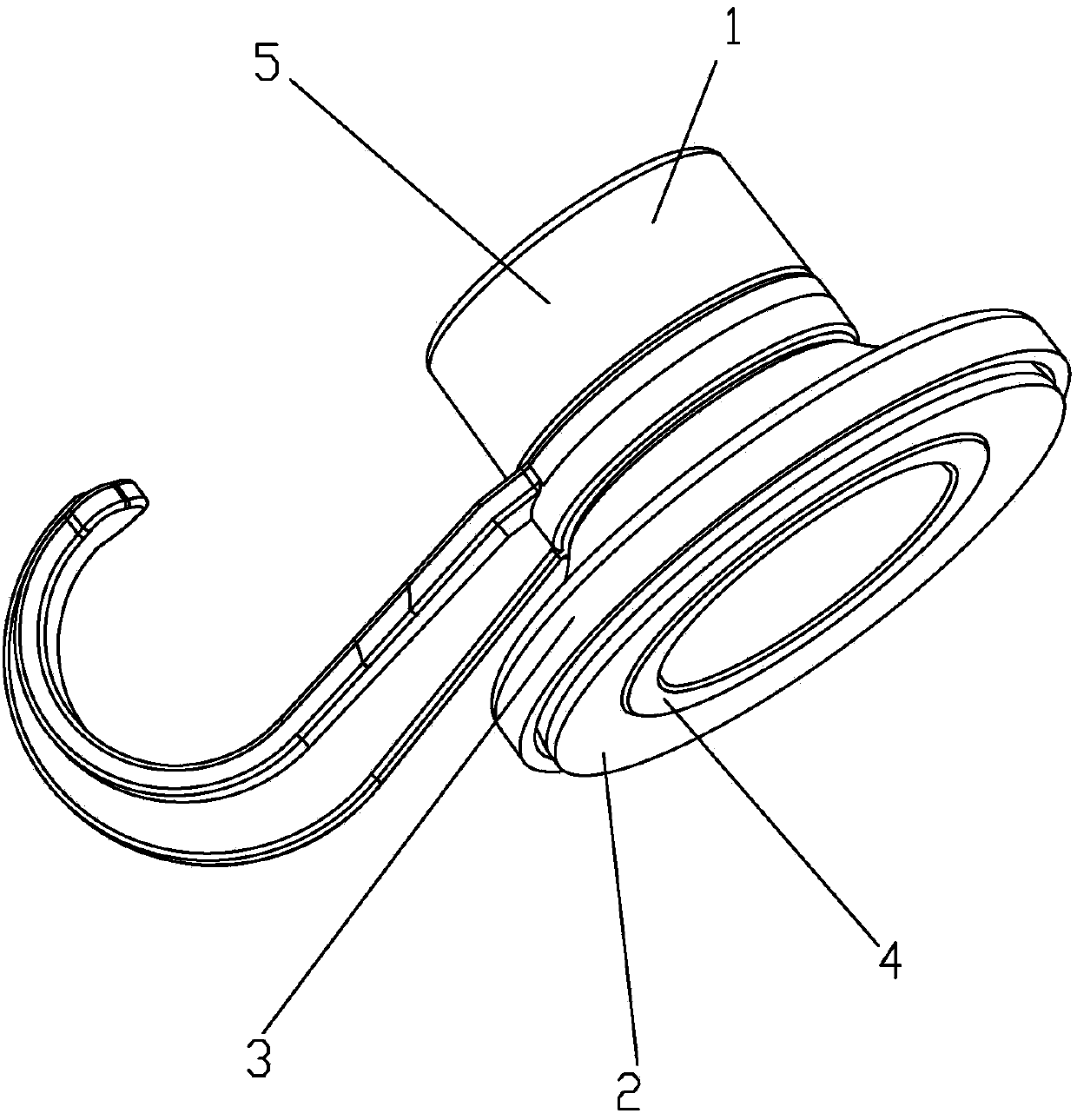

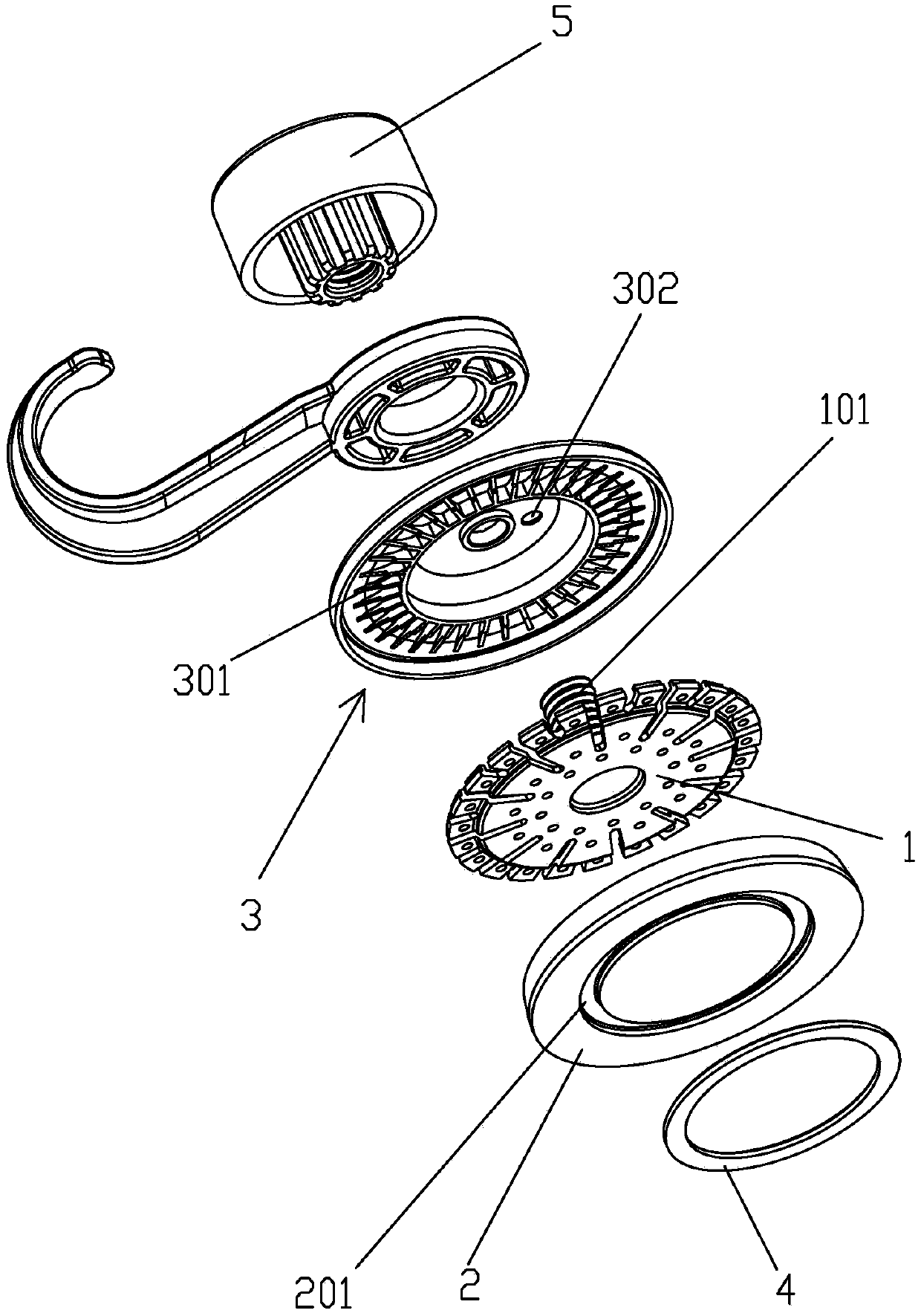

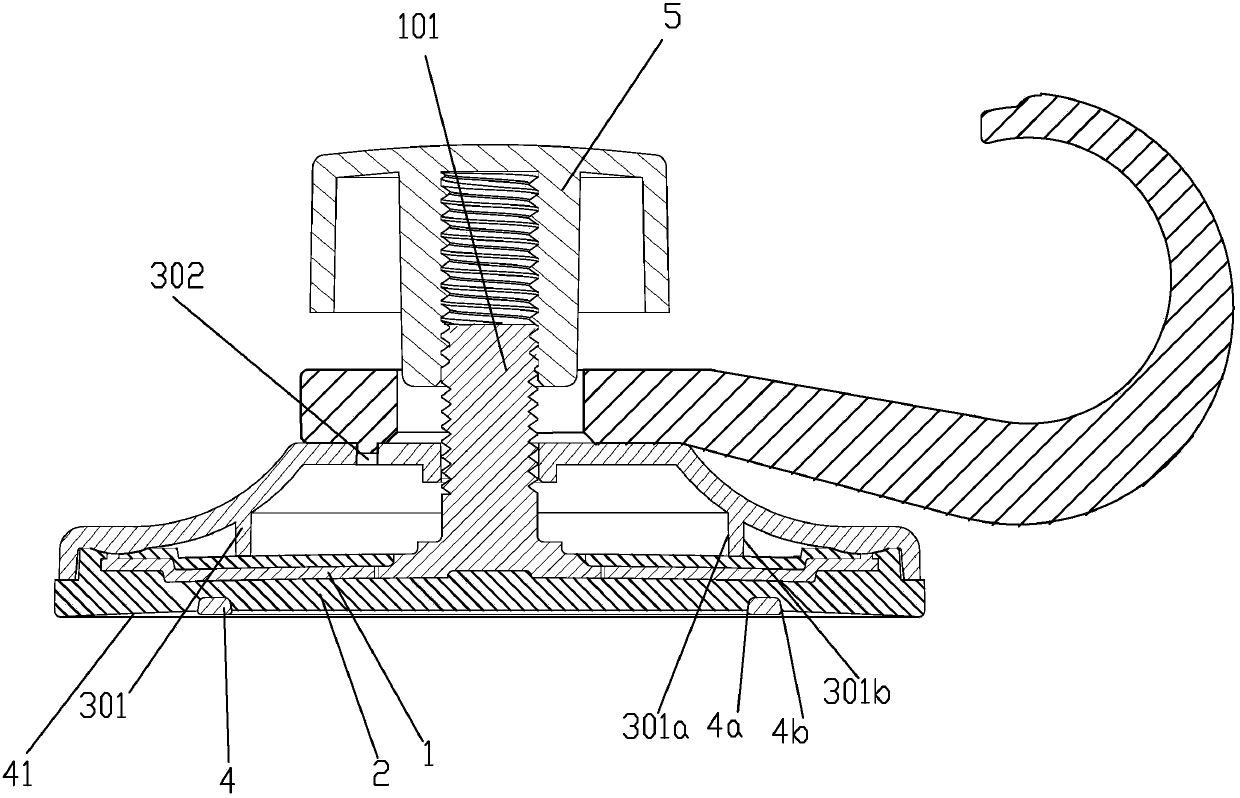

[0059] A suction cup with a seal, including a skeleton 1 covered with elastic colloid 2, a connecting rod 101 is provided on the back of the skeleton 1, and a suction cup cover is set on the connecting rod 101 3. A seal 4 is provided at the bottom of the elastic colloid 2, and a protruding ring 301 that presses against the back of the elastic colloid 2 is provided on the suction cup cover 3, and the back side of the suction cup cover 3 is provided with There is a pressing piece 5 pressed against the back of the suction cup cover 3 and connected with the connecting rod 101 .

[0060] The sealing member 4 is a ring-shaped sealing ring, and is arranged between the bottom edge and the center of the elastic colloid 2, so as to form a contact friction surface 41 on the periphery of the sealing ring. The sealing ring is set between the center and the edge of the elastic colloid 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com