A slider type cardan shaft

A cardan shaft and slider-type technology, applied in the direction of couplings, elastic couplings, lubricating parts, etc., can solve the problems of high maintenance cost, low lubrication efficiency, insufficient filling volume, etc., and achieve high transmission efficiency , low cost and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

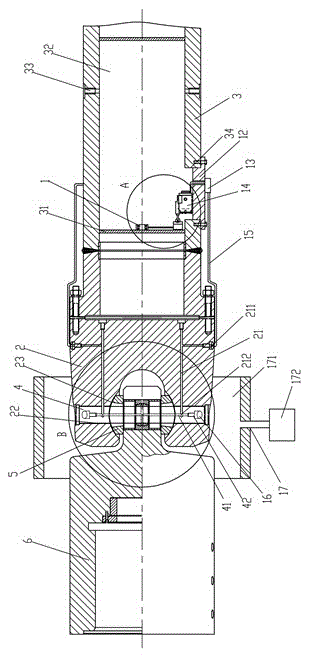

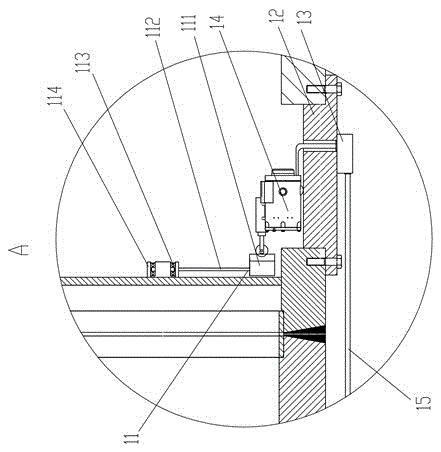

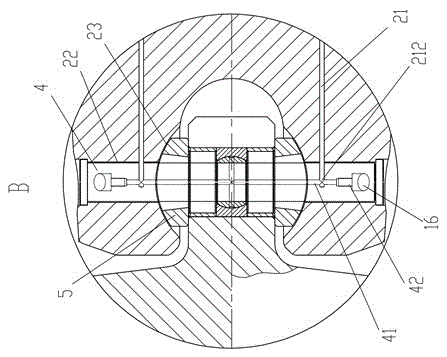

[0019] like figure 1 Shown, the present invention comprises flat joint sleeve 6, tiger's mouth half joint 2, connecting shaft 3, power transmission shaft 4, slide block 5, lubricating device 1, collecting device 17, the left end of tiger's mouth half joint 2 is provided with tiger's mouth 23, passes through tiger's mouth 23 is provided with a transmission shaft installation hole 22 along the axial direction perpendicular to the tiger's mouth half-joint 2, the slider 5 is movably arranged in the tiger's mouth 23, the right end of the flat head sleeve 6 is movably arranged in the slider 5, and the transmission shaft 4 passes through The slider 5 and the flat head socket 6 are installed in the transmission shaft installation hole 22, and the connecting shaft 3 is fixedly arranged on the right end of the half joint 2 of the tiger's mouth. The lubrication device 1 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com