Plate-type chain and installation method thereof

A chain and plate technology, applied in the direction of metal chains, belts/chains/gears, chain elements, etc., can solve the problems of reducing the service life of the chain, short transmission distance, breakage, etc. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

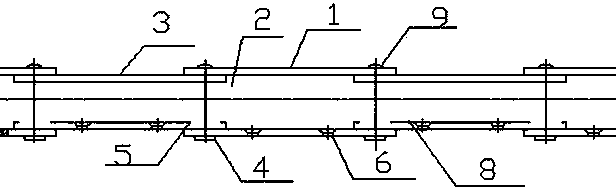

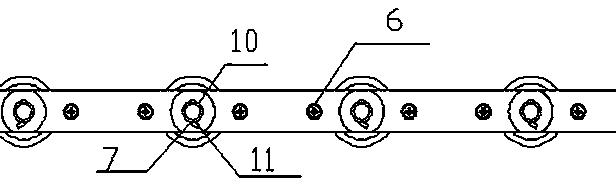

[0019] Attached below figure 1 Detailed description of the preferred embodiment of the present invention: a flyer chain, including an outer chain plate 1, an intermediate roller 2, an inner chain plate 3 and a chain pin 4, the intermediate roller 2 is provided with a middle hole 5, the outer chain plate 1 and the inner The chain plates 3 have the same geometric structure, the inner chain plate 3 and the outer chain plate 1 are provided with link holes 6, and the chain pins 4 are sequentially connected in series with the link holes 6 of the inner link plate 3, the middle hole 5 of the middle roller 2 and the outer chain Link hole 6 of board 1. The outer chain plate 1 and the inner chain plate 3 with the same geometric structure are convenient for installation, and at the same time, the installed flyer chain maintains the consistency of movement during use.

[0020] The intermediate roller 2 is a roller with a tire 8 . The setting of the tire 8 fixes the running track of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com