Masonry construction structure of heating furnace bottom

A masonry structure and heating furnace technology, applied in the direction of lining repair, etc., can solve the problems of prolonging the maintenance period and wasting refractory materials, and achieve the effects of improving operation rate, reducing consumption costs, and reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

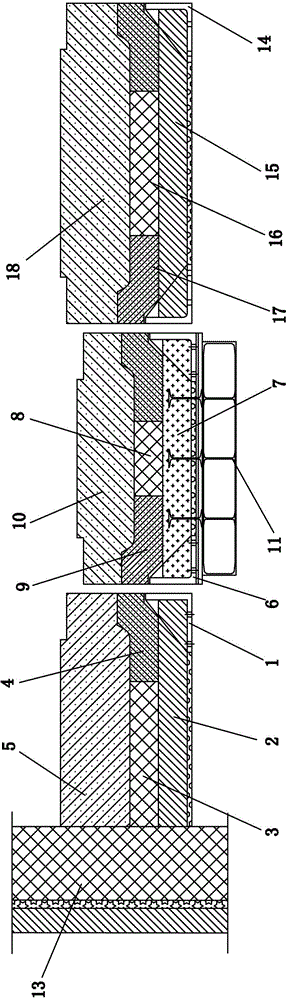

[0011] like figure 1 As shown, a heating furnace bottom masonry structure includes a first fixed bottom, a first movable bottom and a second fixed bottom, the first fixed bottom includes a fixed furnace bottom brick base 1, and the fixed furnace bottom brick base 1 is connected with Furnace floor 2; the first high-strength lightweight brick 3 and the first special-shaped brick 4 are arranged on the furnace floor 2; the first special-shaped brick 4 is built with the first high-strength lightweight brick 3, and the first special-shaped brick 4 is located in the first The right side of the high-strength lightweight brick 3; the first high-strength lightweight brick 3 and the first special-shaped brick 4 are provided with a first unshaped refractory layer 5; the first movable bottom is located on the right side of the first fixed bottom, and There is a certain gap between the first fixed bottoms; the first movable bottom can move up and down relative to the first fixed bottom; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com