Device and method for detecting assembly accuracy of wind turbine wind turbine shroud and hub

A technology for wind turbines and assembly accuracy, which is applied to measuring devices, mechanical devices, mechanical measuring devices, etc., can solve problems such as poor intuition, slow detection speed, and insufficient data, so as to facilitate automatic detection and intuitive display of assembly deviations. clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

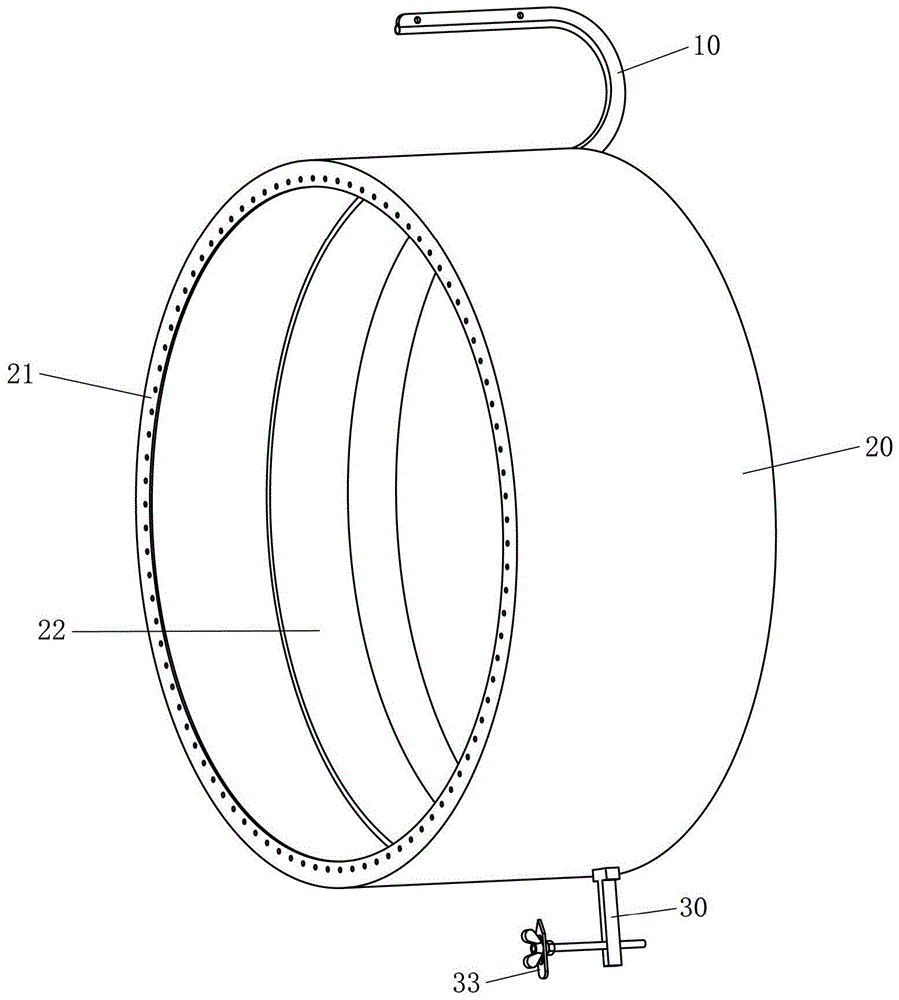

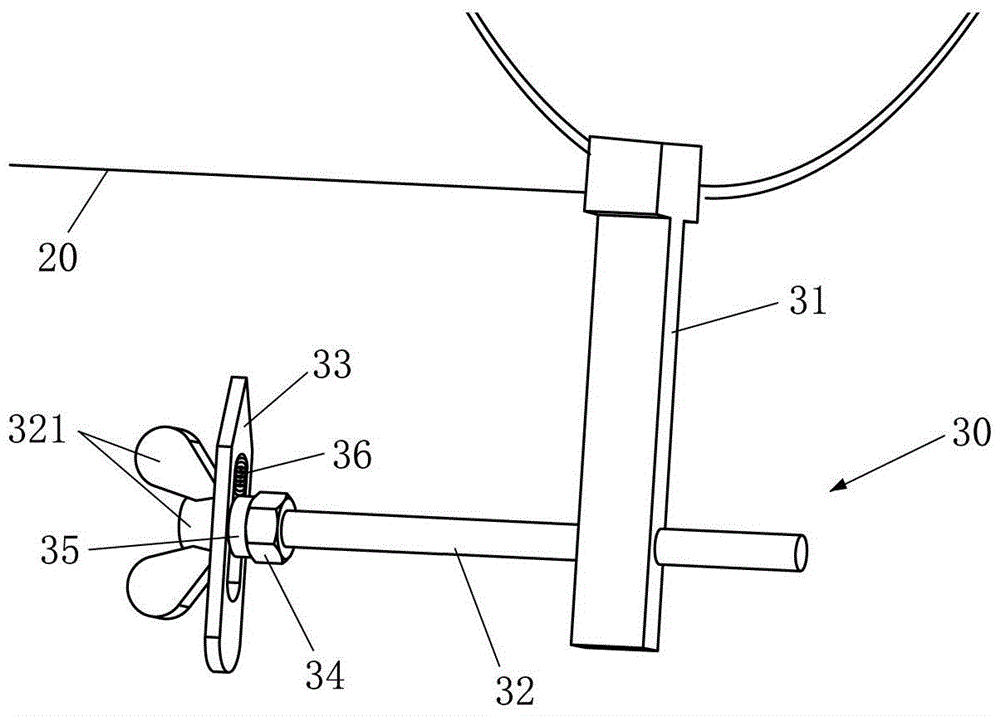

[0026] Such as figure 1 As shown, the detection device for the assembly accuracy of the wind turbine wind turbine shroud and the hub according to the embodiment of the present invention includes a hook 10 and a cylinder 20 .

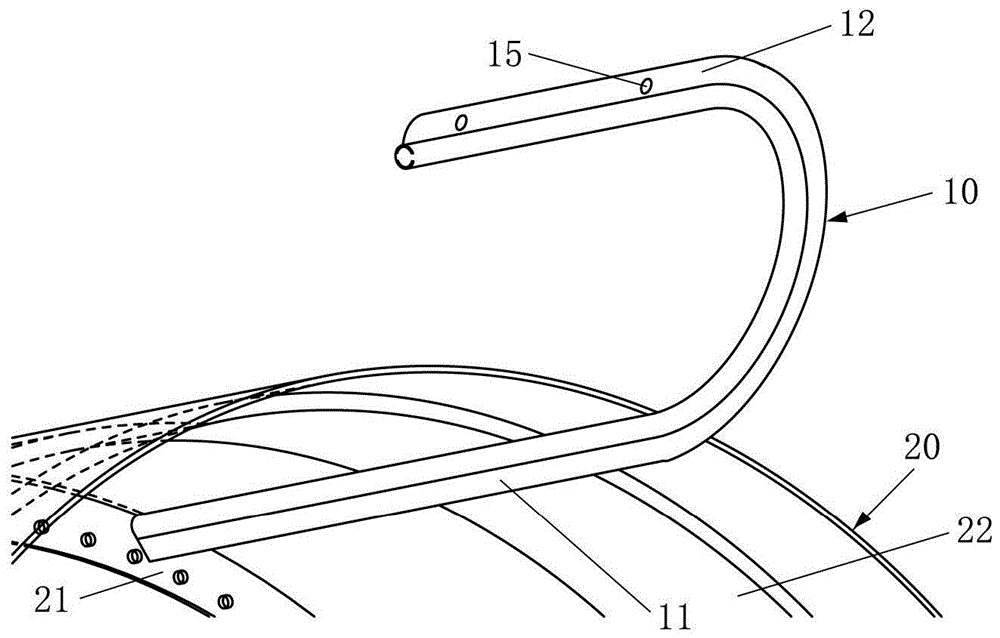

[0027] refer to figure 1 and figure 2 , the hook 10 is U-shaped, and is fixedly connected with the cylinder body 20 . There are at least two lifting holes 15 on the hook 10, a sling shackle can be installed on the lifting holes 15, and the whole detection device can be lifted by a crane by the sling, and installed on the hub pitch slewing bearing.

[0028] The outer diameter of the cylinder body 20 is the same as that of the blade root, and the number of bolt holes and the pitch circle diameter on the cylinder body flange 21 are consistent with those of the blade root flange. During use, the cylindrical body 20 and the hub pitch sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com