Wagon bogie swinging rigidity online detection device and method

A technology for swing stiffness and railway wagons, applied in railway vehicle testing, measuring devices, testing of mechanical components, etc., can solve problems such as the influence of wagon dynamic performance, discrete performance parameters, safety hazards of railway wagon bogies, etc., and achieve data The effect of powerful processing capability, good real-time performance and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

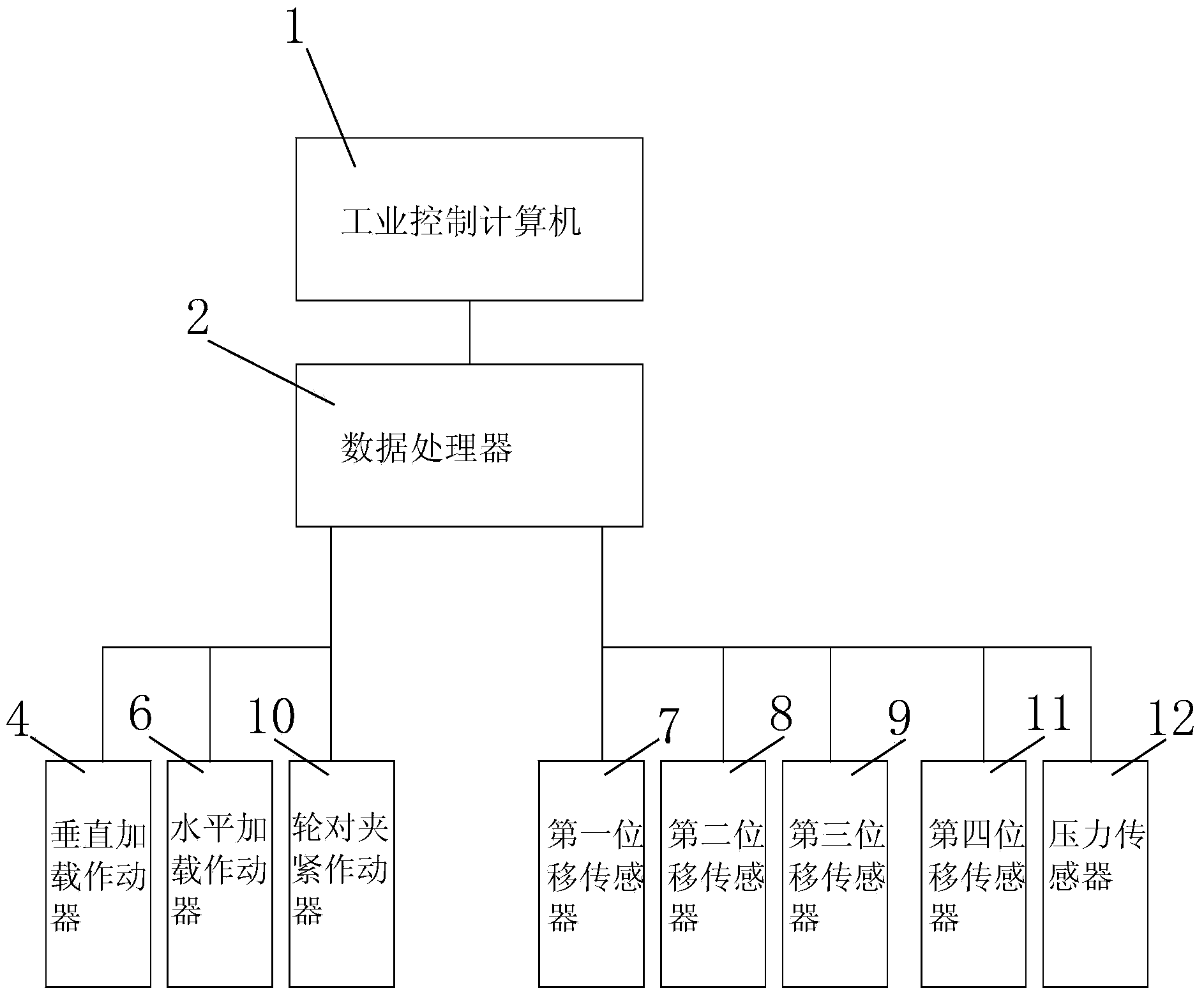

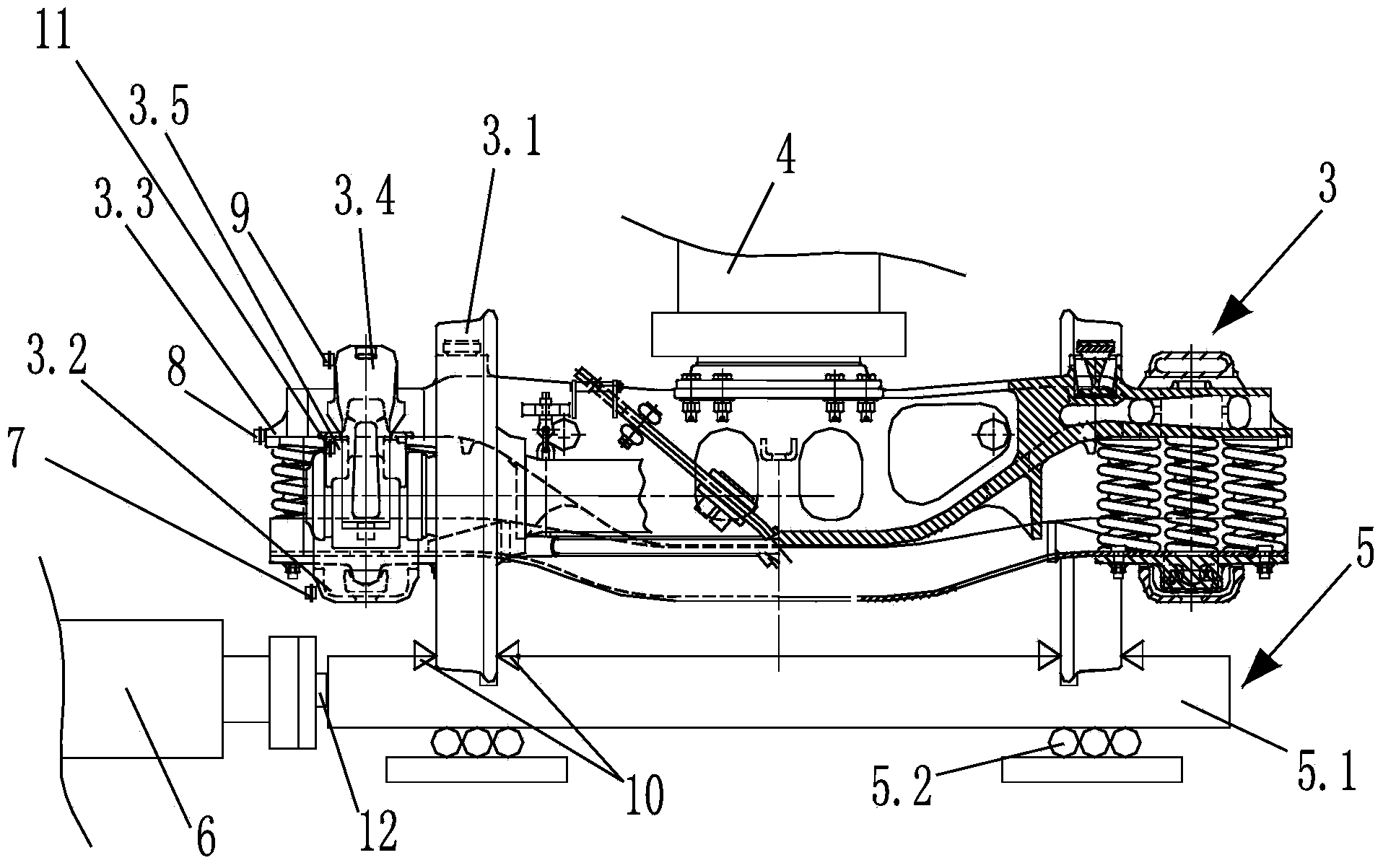

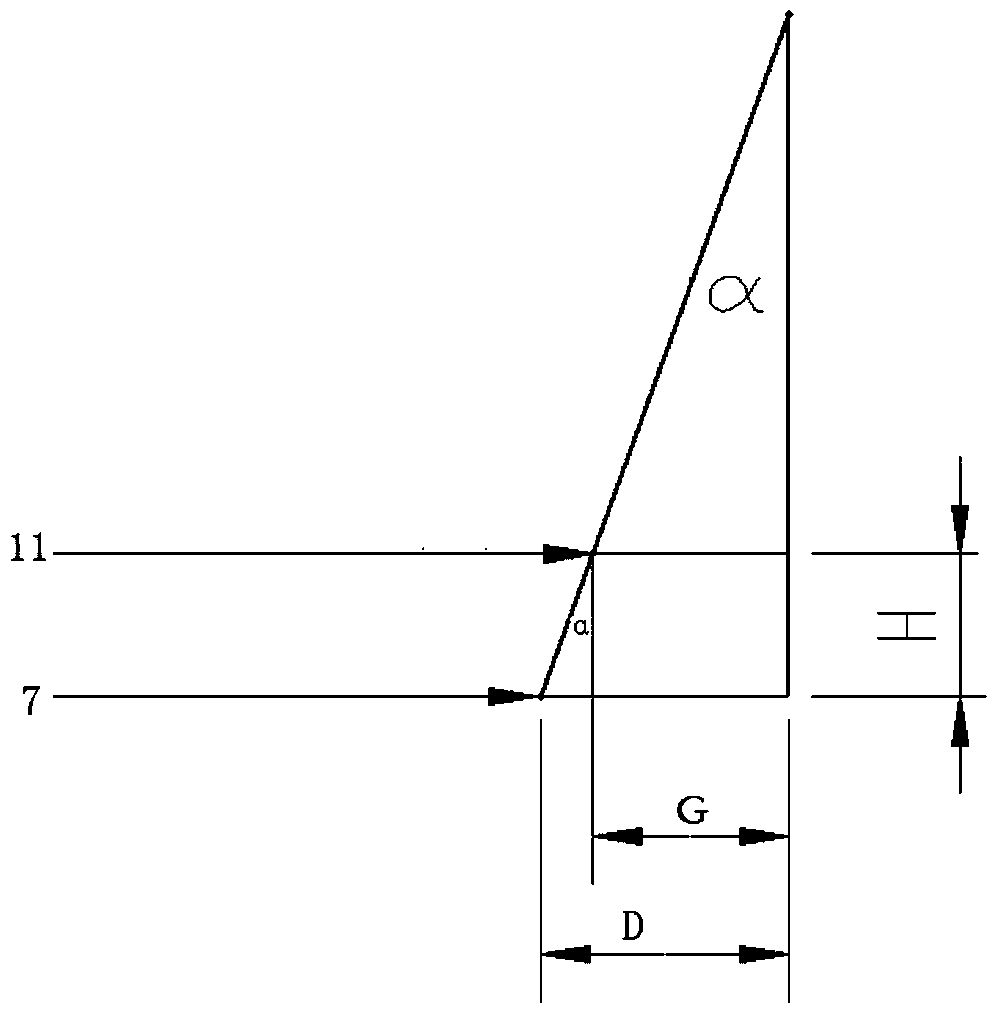

[0036] Such as figure 1 with 2 The shown railway truck bogie swing stiffness on-line detection device includes an industrial control computer 1, a data processor 2 connected to the industrial control computer 1 at the data communication end, and is arranged on the top of the freight car bogie 3 for applying pressure to the freight car bogie 3. A vertical loading actuator 4 for vertical test pressure, a mobile platform 5 arranged at the bottom of the truck bogie 3 for placing the truck truck 3 , and a mobile platform 5 arranged on the mobile platform 5 for clamping the wheels 3.1 of the truck bogie 3 The wheel set clamping actuator 10, the horizontal loading actuator 6 arranged on one side of the mobile platform 5 for applying a horizontal lateral thrust to the mobile platform 5, the first side frame hem point position 3.2 of the truck bogie 3, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap