A performance evaluation method for on-line monitoring sensor of metal particles in flowing oil

A technology for monitoring sensors and metal particles, which is applied in the evaluation field, can solve problems such as unreliability and randomness, increase evaluation costs, and inaccuracy, and achieve accurate and reliable evaluation results, reduce evaluation costs, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

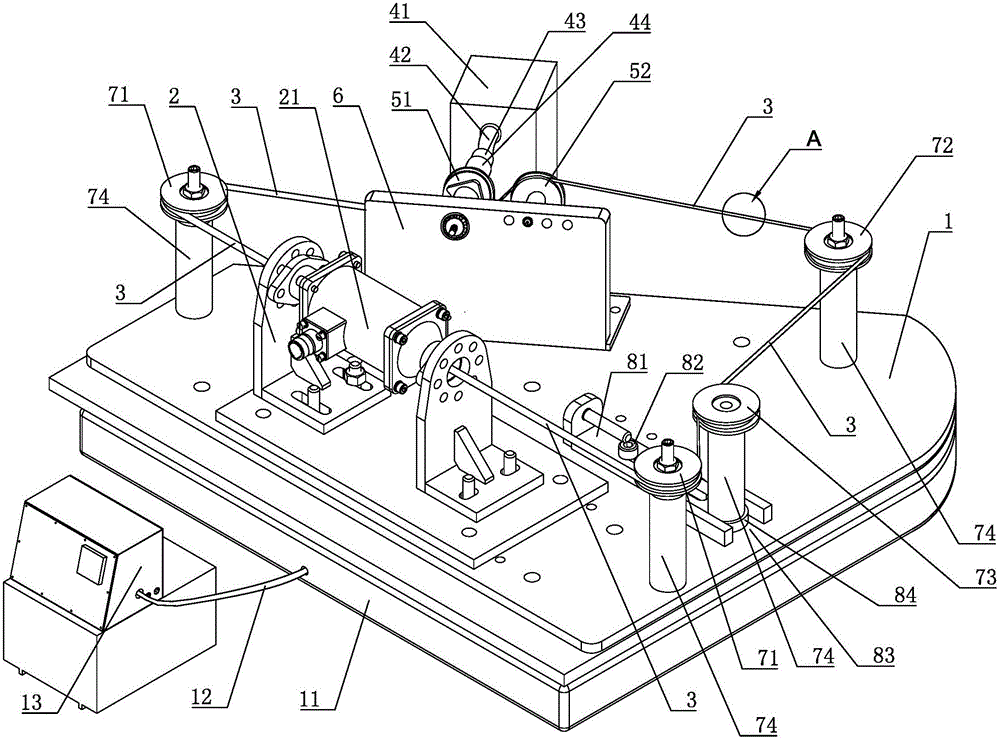

[0029] Embodiment one: if figure 1 As shown, an evaluation method for online monitoring sensor performance of metal particles in flowing oil, including the following steps:

[0030] 1) A bottom plate 1 is set on an existing vibrating table 11, and the vibrating table 11 is connected with the vibrating table control box 13 through the transmission control line 12.

[0031] 2) Fix the support assembly and the sensor installation platform 2 on the bottom plate, and install the conveyor belt driving device on the support assembly. The support assembly includes the main support frame 6 and the auxiliary support frame. The auxiliary support frame is composed of four auxiliary installation columns 74, which will be The evaluated on-line monitoring sensor 21 is fixedly installed on the sensor installation platform 2 .

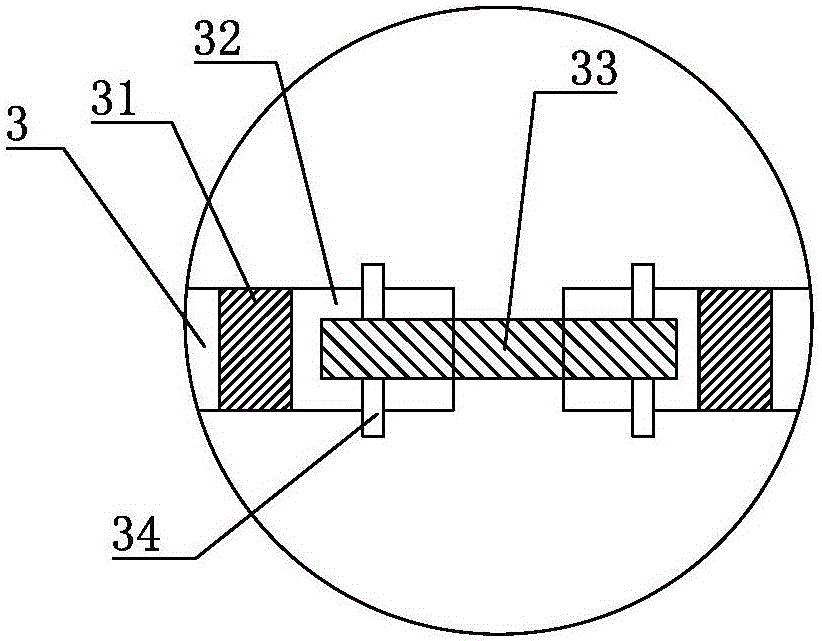

[0032] 3) Install the conveyor belt driving device: the conveyor belt driving device includes a motor 41, a drive shaft, a driving wheel group and a driven wheel grou...

Embodiment 2

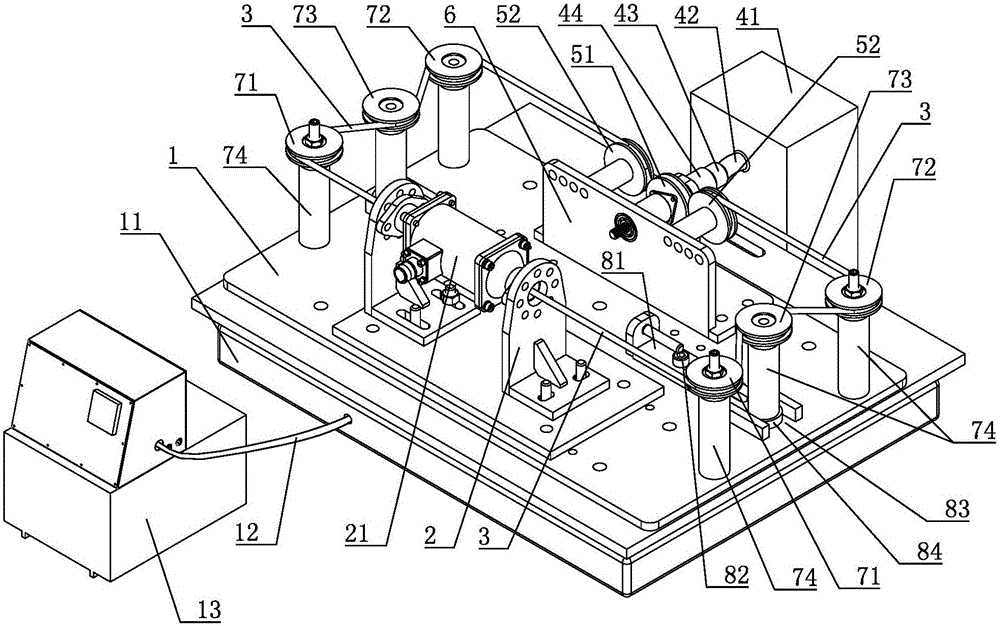

[0039] Embodiment two: if image 3 and Figure 4 As shown, the remaining parts are the same as in Embodiment 1, the difference is that there are two main tension pulleys 52, the main drive pulley 51 is located between the two main tension pulleys 52, there are two slave drive pulleys 72, and there are two slave tension pulleys. 73 is two, and the auxiliary support frame is made up of six auxiliary mounting posts 74, and two slave driving wheels 72 are arranged on both sides of the main driving wheel 51, and the slave driving wheels 72 are positioned at the adjacent end limit wheel 71 and the main tension wheel. 52, the slave tension wheel 73 is located between the slave drive wheel 72 and the end limiting wheel 71 adjacent to the slave drive wheel 72.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com