Method for magnetizing main and subsidiary magnets of external-magnetic dual-magnet loudspeaker

A magnetization method and loudspeaker technology, applied in the field of loudspeakers, can solve the problems of wasting time and space, instability of main magnetism and auxiliary magnetism, inconvenient production, etc., and achieve the effects of saving time, avoiding the jumping of auxiliary magnetism, and stabilizing magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

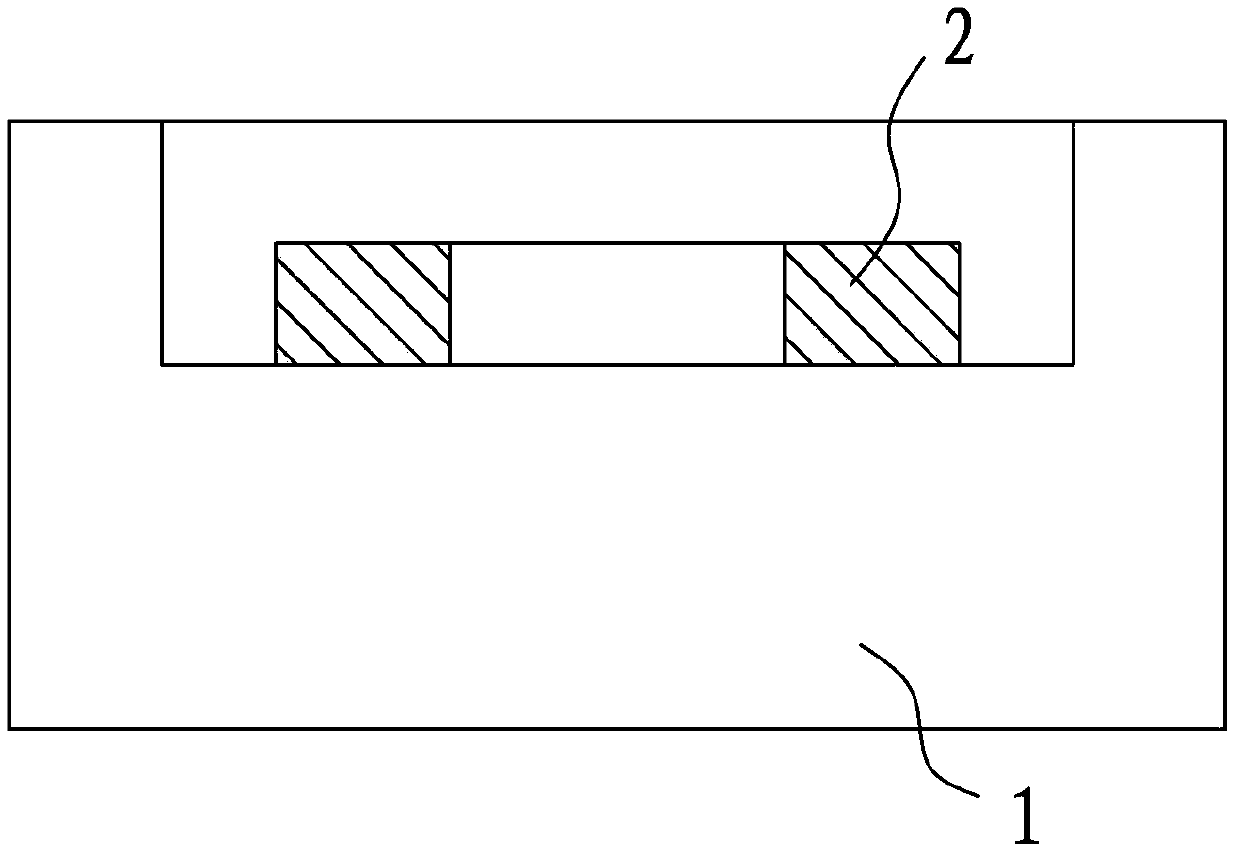

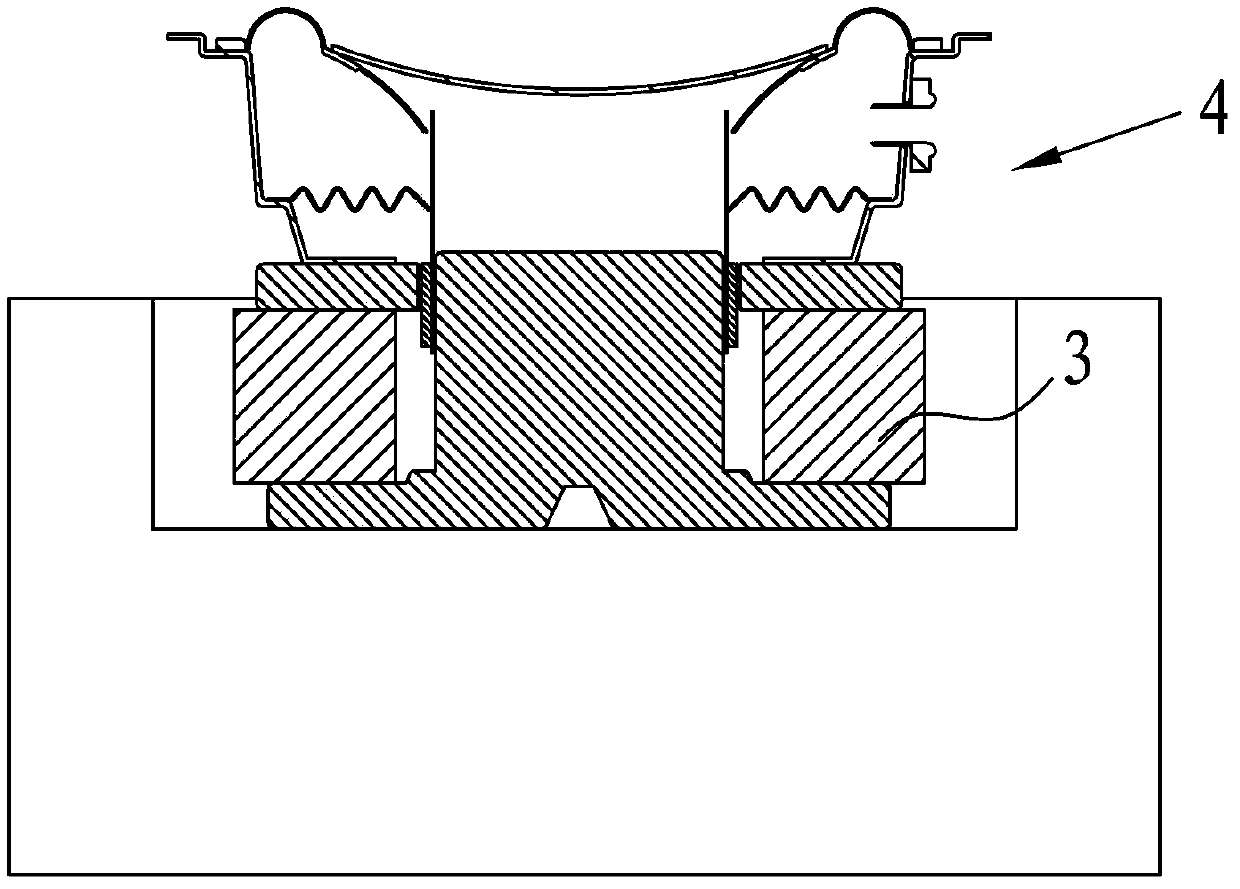

[0017] Embodiment one: see attached image 3 As shown, place the auxiliary magnet 2 on the magnetizer machine 1, then place the speaker frame 4 with the main magnet 3 on the auxiliary magnet 2, and apply a certain downward pressure on the speaker frame 4 to ensure that the During the magnetization process, the positional relationship between the main magnet 3 and the auxiliary magnet 2 remains unchanged, and the magnetizer switch is turned on for magnetization.

[0018] After magnetization, the magnetic poles of the main magnet 3 and the auxiliary magnet 2 are opposite to each other, which will weaken the magnetic field strength of the speaker, and the auxiliary magnet 2 can be assembled upside down during assembly.

Embodiment 2

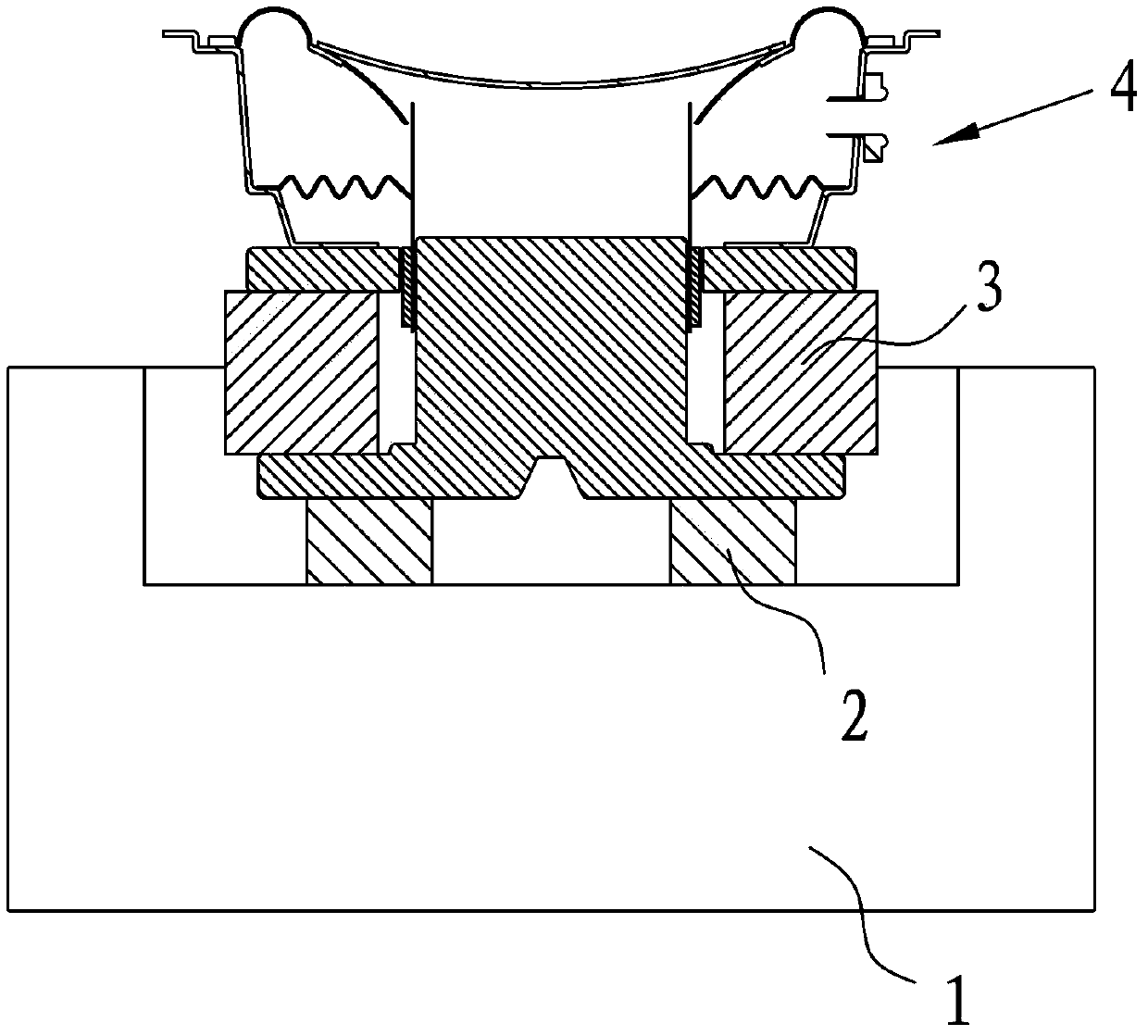

[0019] Embodiment two: see attached Figure 4 As shown, the auxiliary magnet 2 is set in the magnetic shield 5, the magnetic shield 5 is turned upside down on the magnetizer machine 1, and the speaker frame 4 with the main magnet 3 installed is placed above the auxiliary magnet 2, and the speaker frame 4 Apply a certain downward pressure on the top to ensure that the positional relationship between the main magnet 3 and the auxiliary magnet 2 remains unchanged during the magnetization process, and turn on the switch of the magnetizer for magnetization.

[0020] After magnetization, turn over the magnetic shield 5 and assemble it with the speaker frame 4 .

[0021] In the above embodiment, the main magnet 3 and the auxiliary magnet 2 are magnetized at the same time, only one magnetizer is needed to complete the magnetization process, and after magnetization, the subsequent assembly can be carried out without transportation, which saves time, manpower and production Resou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com