Phase change heat sink

A heat dissipation device and phase change technology, applied in the field of phase change heat dissipation devices, can solve the problems of staff's discomfort in operation and unusable heat dissipation fins, and achieve the effect of avoiding excessive temperature rise and high utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

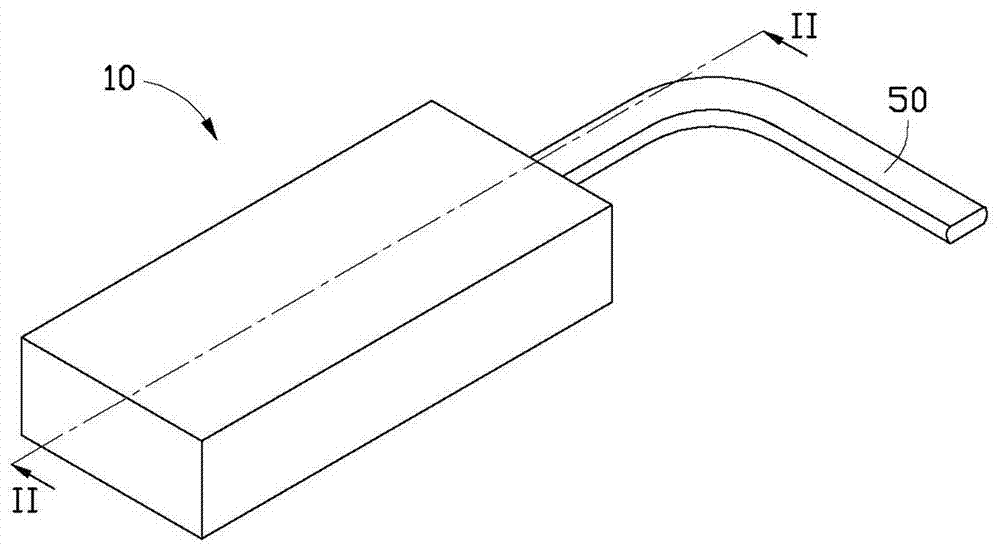

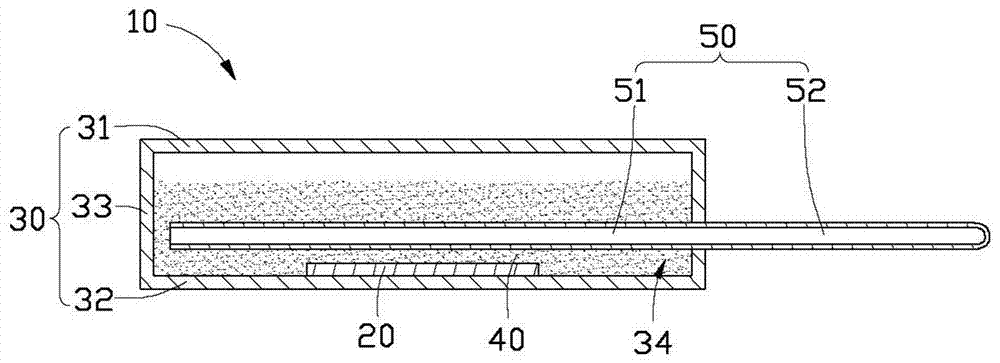

[0012] The phase change heat dissipation device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] Please also see Figure 1 to Figure 2 , the phase change heat sink 10 of a preferred embodiment of the present invention is used to dissipate heat from the heating element 20 in the electronic device (not shown), which includes a housing 30 and a working medium arranged in the housing 30 40 and a heat pipe 50 connected to the shell 30.

[0014] Specifically, the housing 30 includes an upper cover 31 , a lower cover 32 opposite to the upper cover 31 , and a side wall 33 connecting the upper cover 31 and the lower cover 32 . Both the upper cover 31 and the lower cover 32 are flat and the size of the upper cover 31 is slightly larger than the size of the lower cover 32. The side wall 33 is formed by bending and extending upward from the periphery of the lower cover. The edge of the upper cover 31 is in contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com