Universal dispenser

A technology for dispensing machines and casings, which is used in coatings, devices for coating liquids on surfaces, etc., and can solve problems such as low glue coating accuracy, low efficiency, and unreasonable flow control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

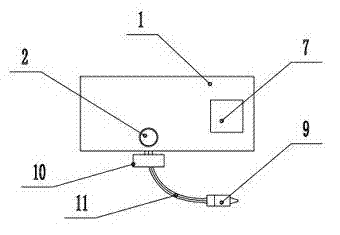

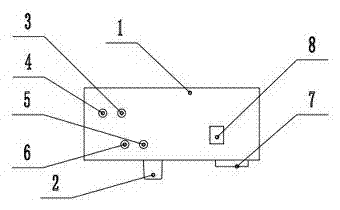

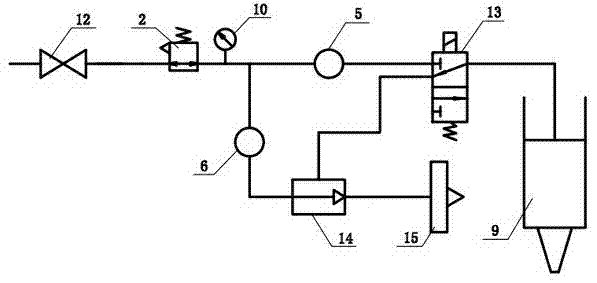

[0012] The present invention will be further explained below in conjunction with the drawings in the specification:

[0013] The universal glue dispenser of the present invention includes a casing 1 and an air source 12. The front end of the casing 1 is provided with a dispensing head 9 and a pressure gauge 10, the upper end of the casing 1 is provided with a dispensing pressure regulating valve 2 and a time relay 7, and the casing 1 The back end is equipped with air source inlet 3, power cord 4, glue discharge air flow regulating valve 5, vacuum flow regulating valve 6 and power switch 8. The gas source 12 is connected to the gas source inlet 3, between the gas source inlet 3 and the glue nozzle 9 It is the air pipe 11, and the air pipe 11 between the air source inlet 3 and the rubber ejection head 9 is provided with an ejection pressure regulating valve 2, a pressure gauge 10, a rubber ejection air flow control valve 5, and a solenoid valve 13 in sequence; 5 A vacuum flow regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com