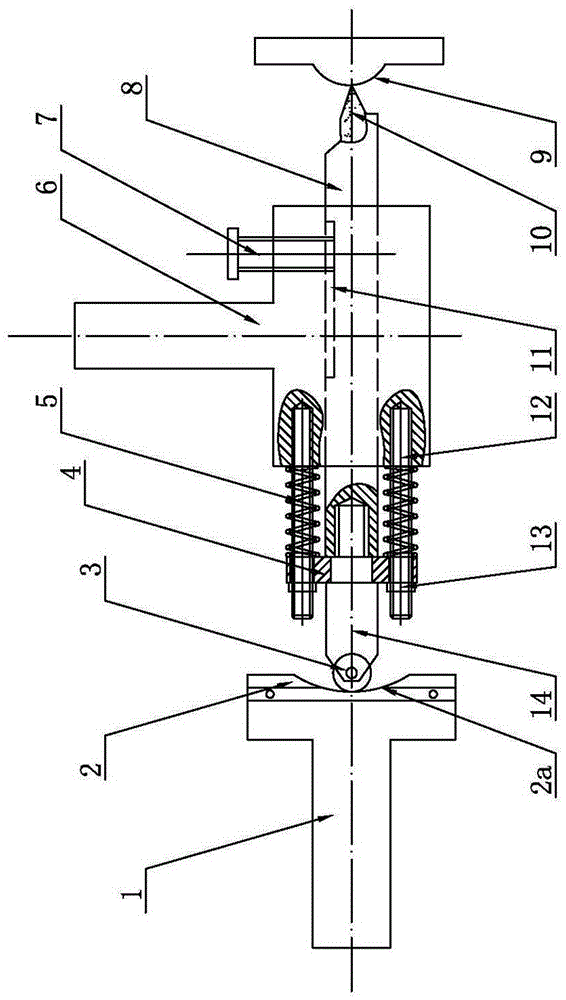

Triangular door steel waterproof curved surface processing device

A processing device and arc surface technology, applied in metal processing equipment, manufacturing tools, replication process control systems, etc., can solve the problems of low strength of rubber materials, difficult processing, and quality level affecting the safe operation of hydraulic gates. Simple, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

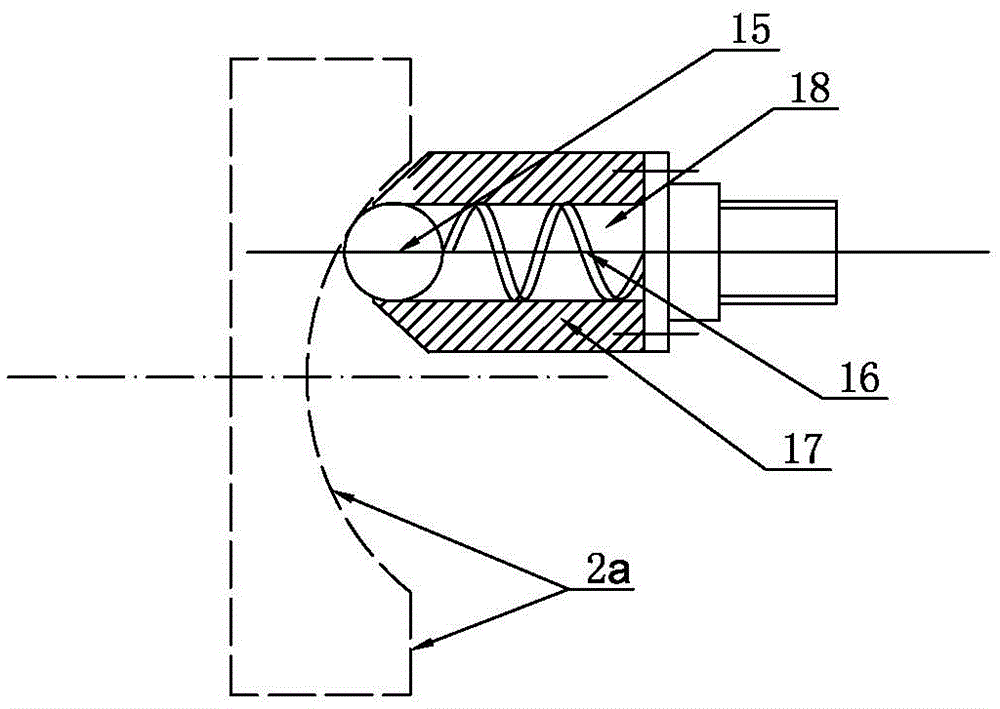

Embodiment 2

[0017] Such as image 3 As shown, the difference from Embodiment 1 is that the guide device includes a guide ball 15 that abuts on the profiled surface 2a, and the guide ball 15 is arranged in the central hole 18 of the guide ball frame 17, and the guide ball frame 17 and the tool bar 8 ends are fixedly connected, and a support spring 17 is provided in the central hole to support on one side of the guide ball 15, and the elasticity of the support spring 17 is much greater than that of the return spring 5. When the workpiece is processed, the support spring 17 can ensure that the guide ball is always in contact with the profiling surface 2a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com