Horizontally wound coil assembly and disassembly mechanism

A loading and unloading mechanism and coil technology, applied in hand-held tools, manufacturing tools, inductance/transformer/magnet manufacturing, etc., to avoid failure due to bending and deformation of the winding shaft, simple and reasonable loading and unloading mechanism, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

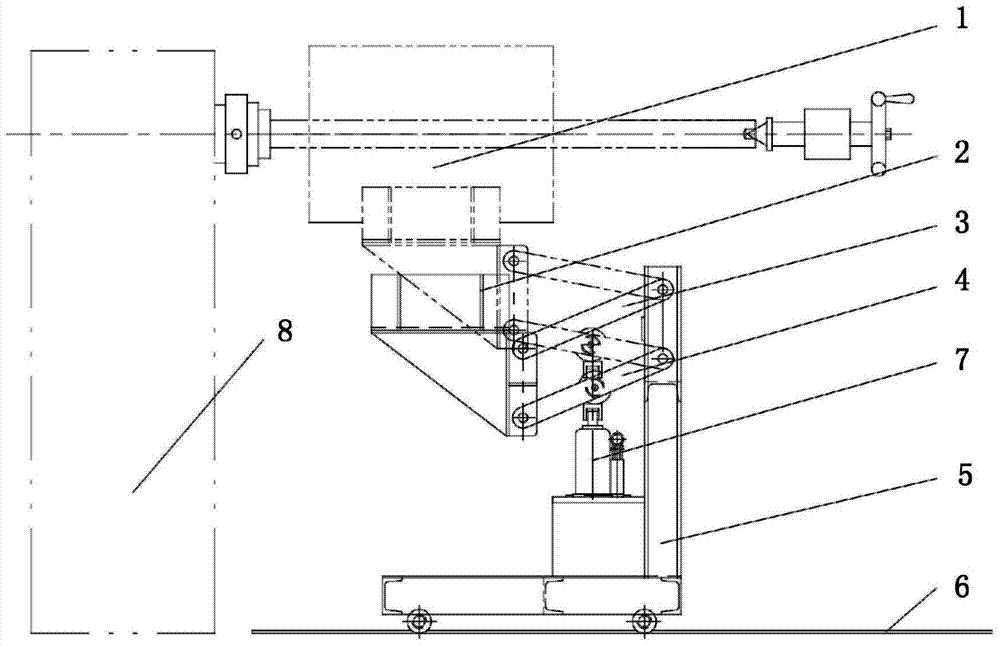

[0037] A horizontal wound coil loading and unloading mechanism, such as figure 1 As shown, including trays, linkages, jacks, racks and rails, for loading and unloading of small and medium-sized circular and oval coils,

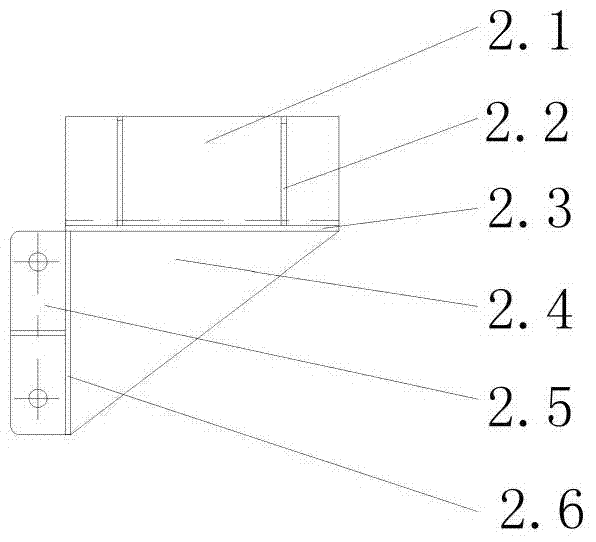

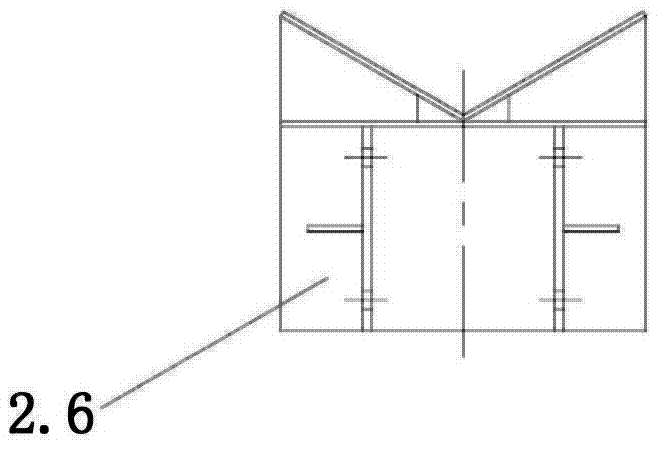

[0038] The tray has a supporting plate bent at a certain angle, which is used to hold the coil and prevent it from rolling; the connecting rod has an upper connecting rod and a lower connecting rod, and the two ends of the upper connecting rod and the lower connecting rod are respectively It is rotatably connected with the tray and the frame, and the part of the shaft connection on the same side forms a parallelogram to ensure the stable lifting of the coil during the process of unloading and loading the coil;

[0039] The frame is used to bear the weight of the coil and the action of all parts of the installation mechanism, and cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com