a cable winch

A towing winch, stranding machine technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of slow braking speed of the brake belt, difficult rotation of the drum, and poor resilience of the brake belt, etc. Guaranteed installation requirements and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

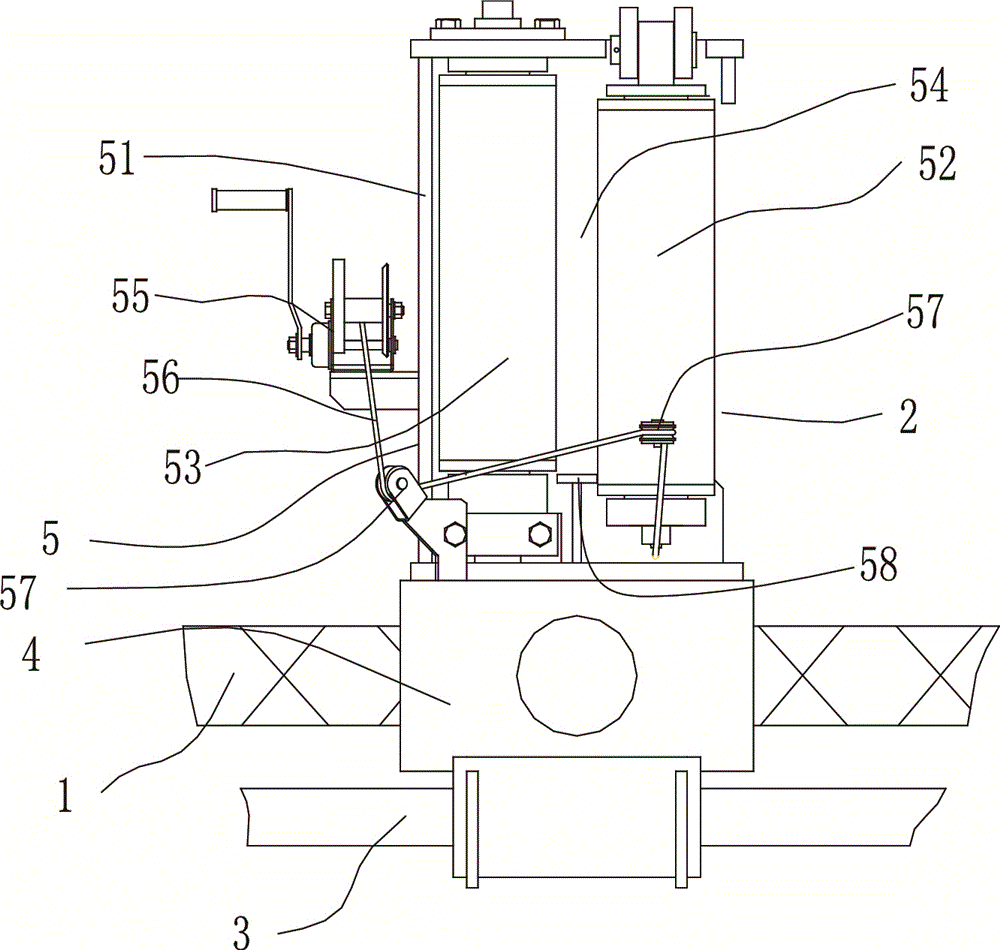

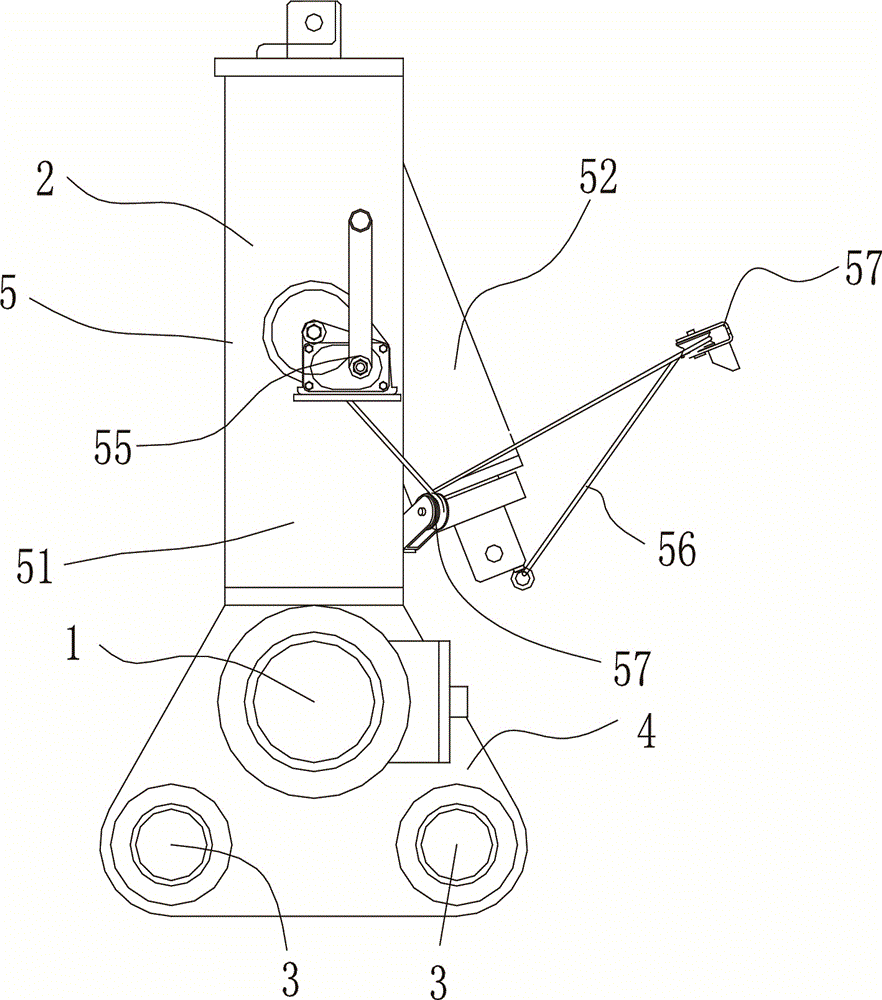

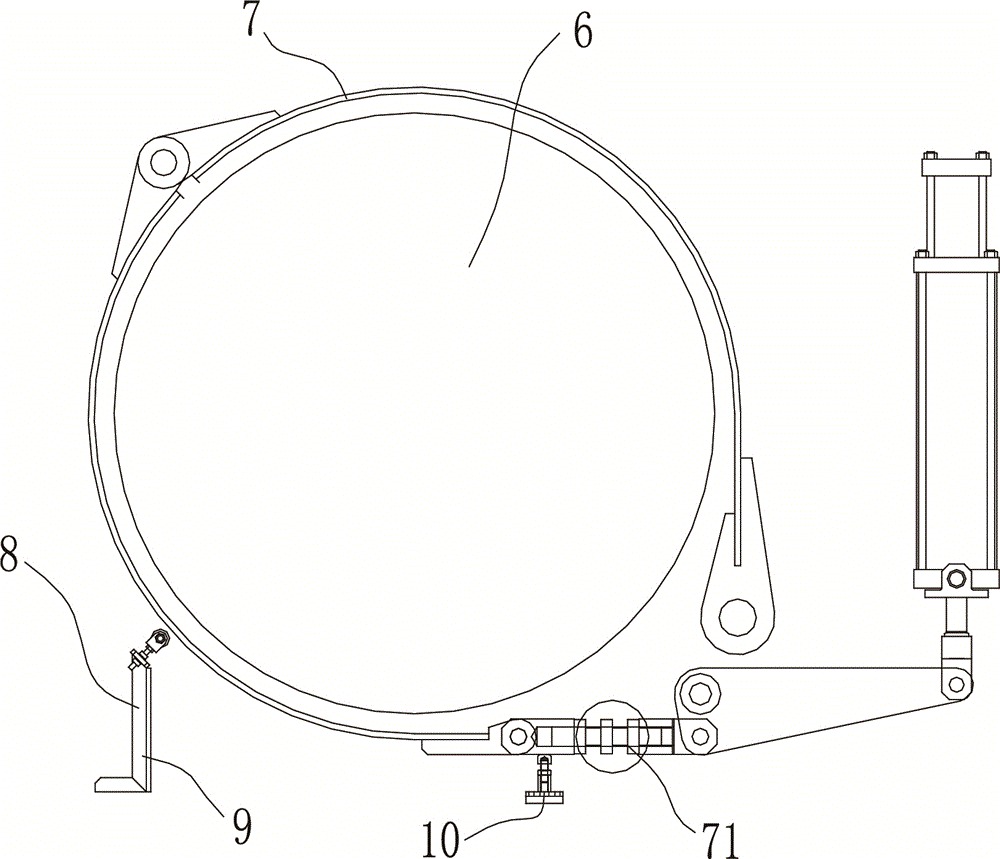

[0025] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 6 , a tow cable winch, including a cable arrangement, the cable arrangement includes a two-way screw 1, a guide wheel 2, a guide rod 3, the guide wheel 2 includes a base 4 and a guide part 5, the two-way screw 1 and the guide rod 3 The guide rod 3 passes through the base 4 of the guide wheel 2, the two-way screw 1 is parallel to the guide rod 3, and the guide part 5 is composed of a frame body 51 and a first rotating shaft arranged in the frame body 51. 52 and the second rotating shaft 53, the frame body 51, the first rotating shaft 52, and the second rotating shaft 53 form a wire hole 54, the rear side drum 6 of the cable arrangement device, and the outer side of the drum 6 is set There is a brake band 7, the upper end of the first rotating shaft 52 is rotationally connected with the frame body 51, the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com